“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for 100% Original Factory China 300W YAG Laser Spot Welding Machine for Metal&Jewelry, Our company has been devoting that “customer first” and committed to helping clients expand their organization, so that they become the Big Boss !

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for China Welder, Spot Welder, We’ve got been in operation for more than 10 years. We are dedicated to quality products and consumer support. We currently own 27 product utility and design patents. We invite you to visit our company for a personalised tour and advanced business guidance.

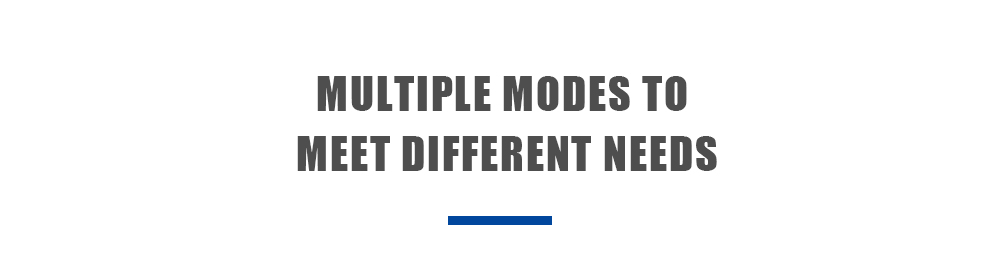

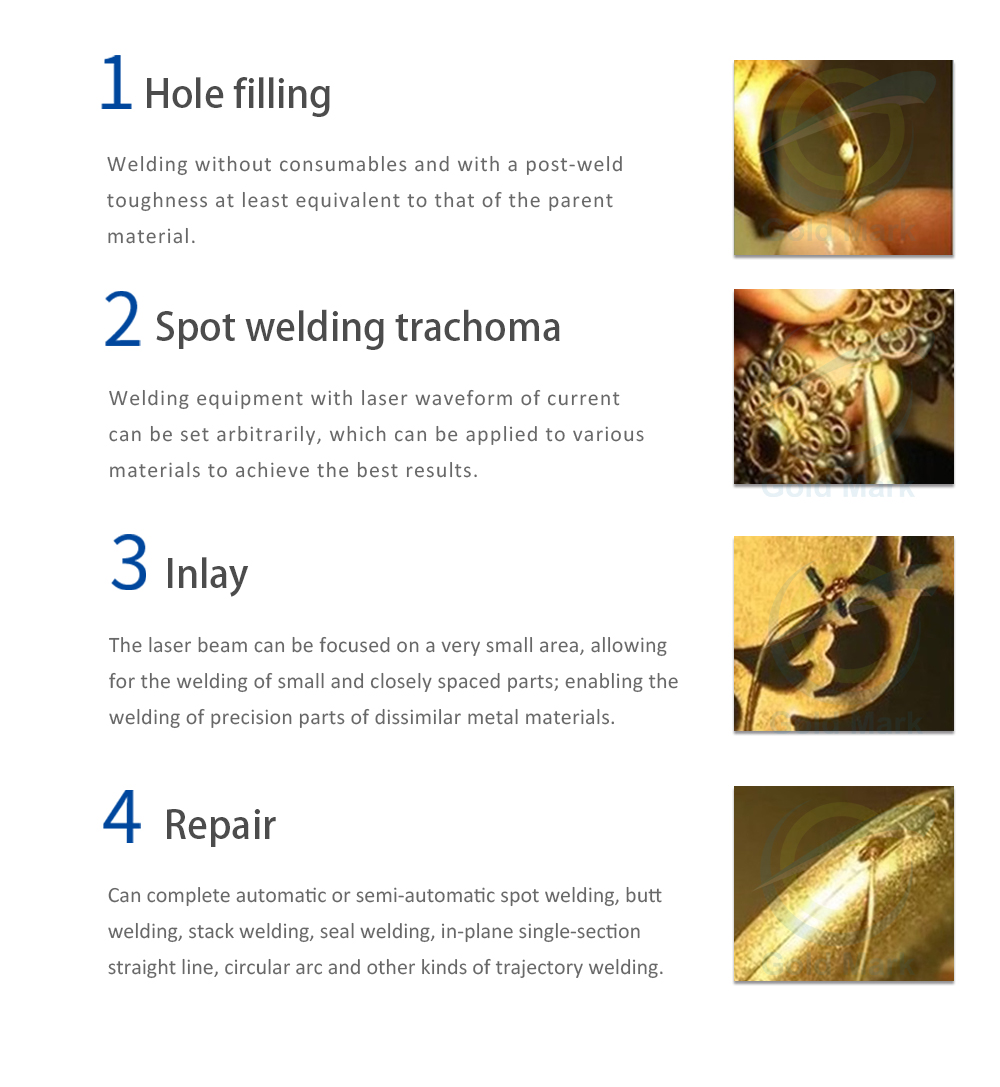

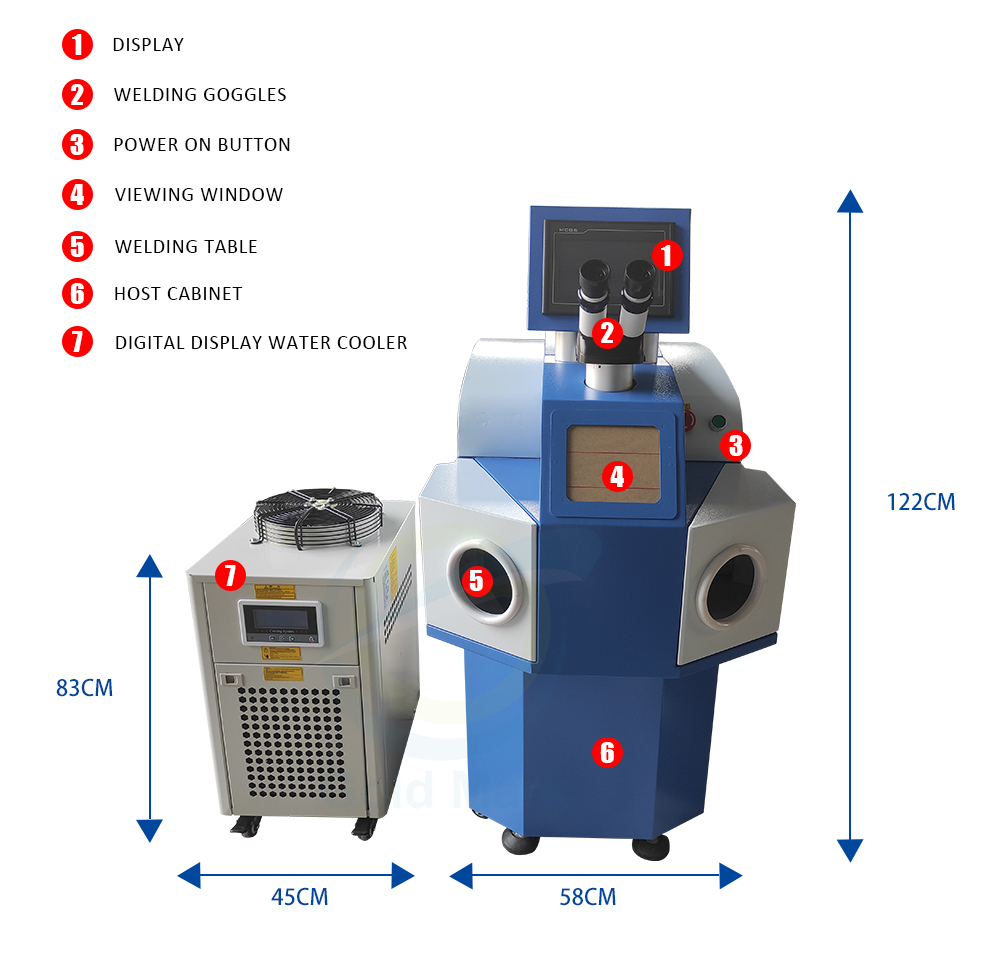

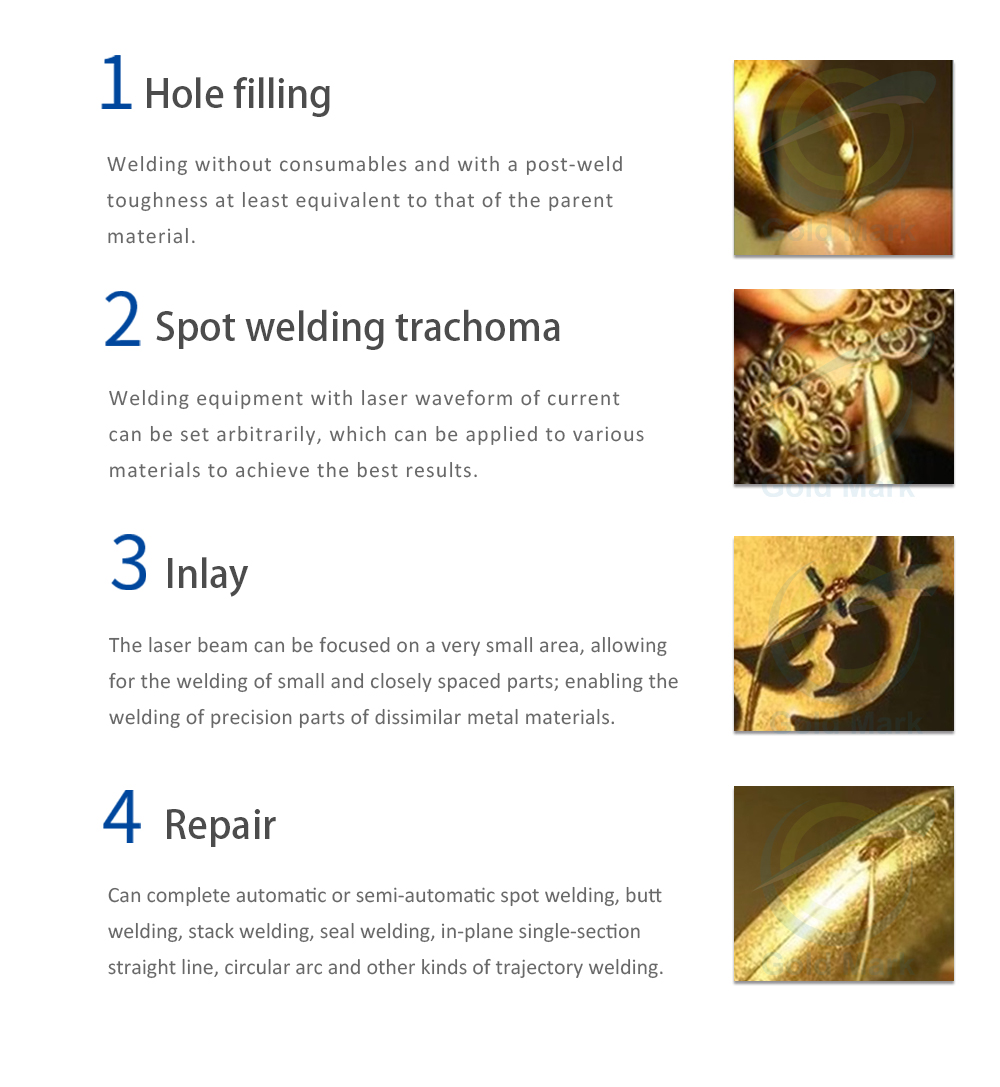

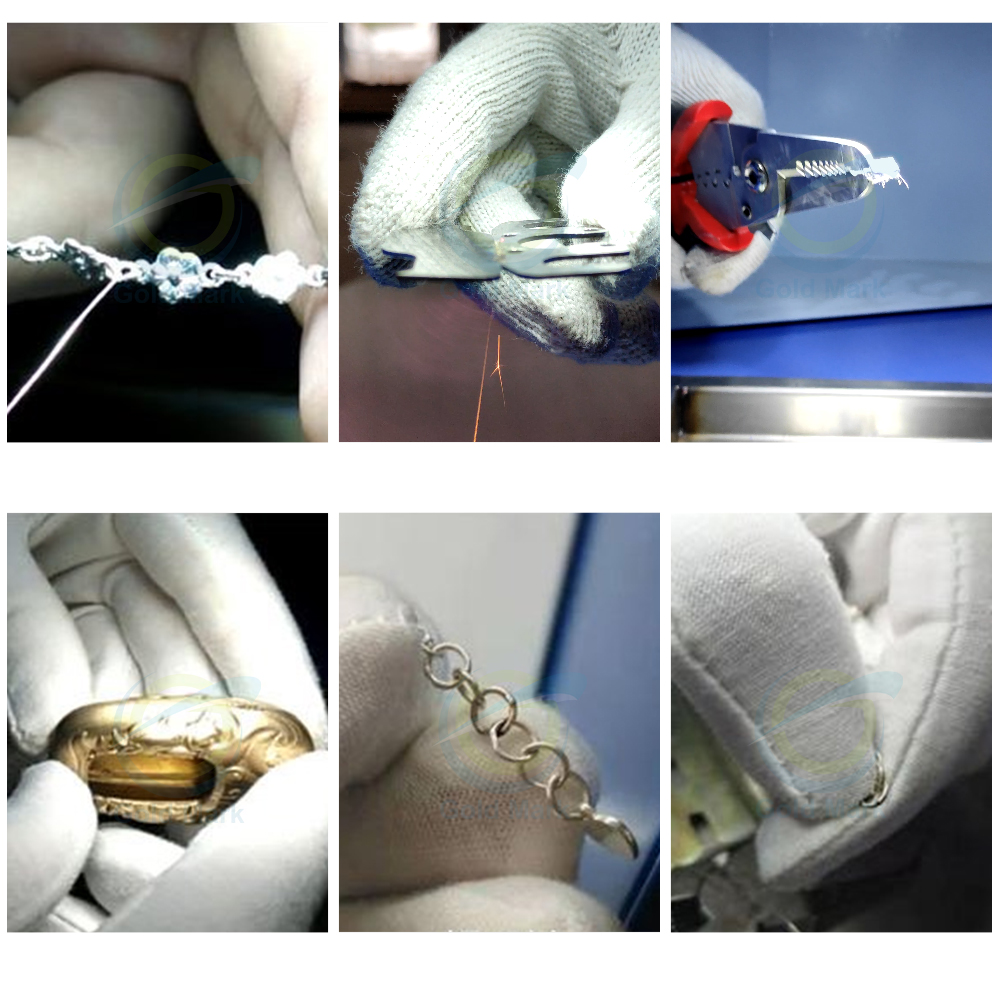

This laser spot welding machine is specially used for gold and silver jewelry, golf balls, electronic components to fill holes, spot welding trachoma, welding inlay, etc.. The welding is firm, beautiful, no deformation, simple operation, easy to learn and use, etc. It has the advantages of fast speed, high efficiency, large depth, small deformation, small heat-affected zone, etc. The welding quality is high, and the welded joint is pollution-free and environmentally friendly.

Widely used in cell phone communication, electronic components, new energy,jewelry and accessories, hardware products, precision instruments, auto parts, craft gifts and other industries.

Micro parts precision processing including: jewelry, jewelry, golf head and aluminum alloy denture, etc., especially suitable for gold and silver jewelry patching holes, spot welding trachoma, repairing seam lines and inlay parts claw foot parts, etc.

|

Model

|

LM-200 Laser Welding Machine

|

|

Output Power

|

100 W I 200 W I 300 W – based on requirement

|

|

Single-pulse energy

|

0-100 J

|

|

Machine Design Type

|

Desktop I Vertical

|

|

Laser Source

|

ND: YAG

|

|

Laser Wavelength

|

1064 nm

|

|

Pump lamp

|

Pulsed Xenon Lamp

|

|

Pulse Width

|

0.1.15 ms adjustable

|

|

Pulse Repeated Frequency

|

1 — 20 Hz adjustable

|

|

Welding spot diameter

|

0.2-1.5 mm adjustable

|

|

Observing System

|

Microscope I CCD – based on requirement

|

|

Cooling System

|

Water chiller

|

|

Power Supply

|

Single Phase AC 220V ± 10%, 50Hz I 60HZ, 4 KW

|

|

Running Environment

|

Temperature 5°C-28°C Humidity 5%-70%

|

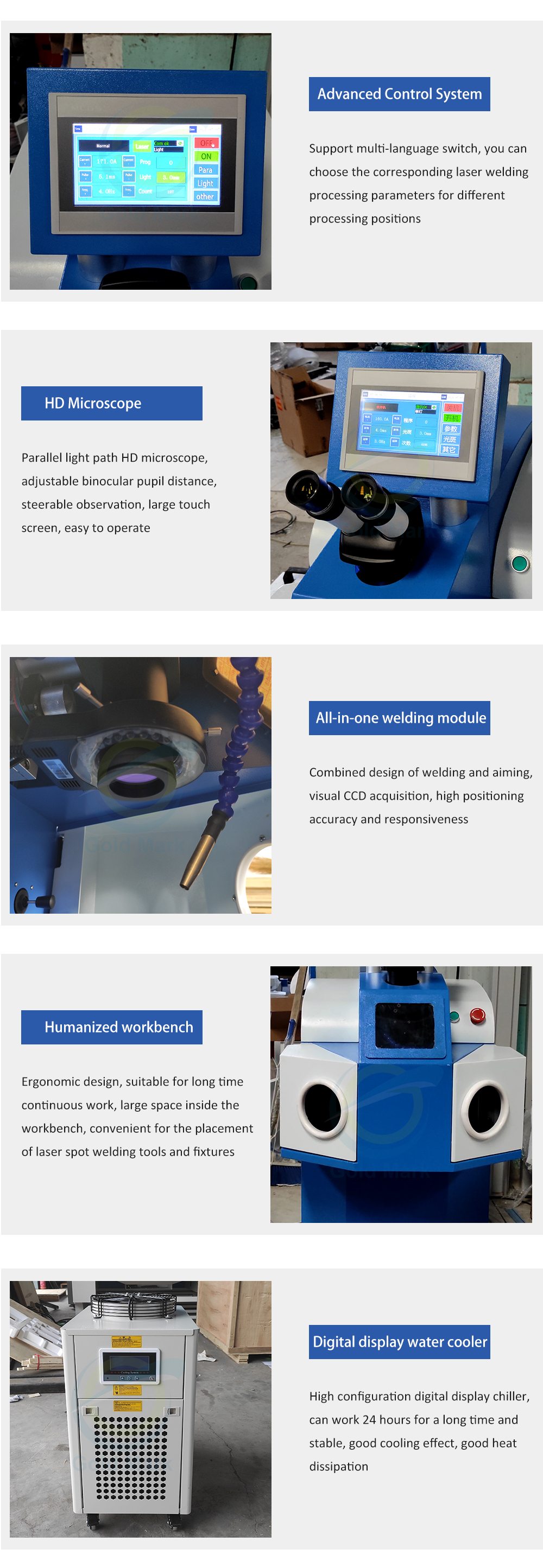

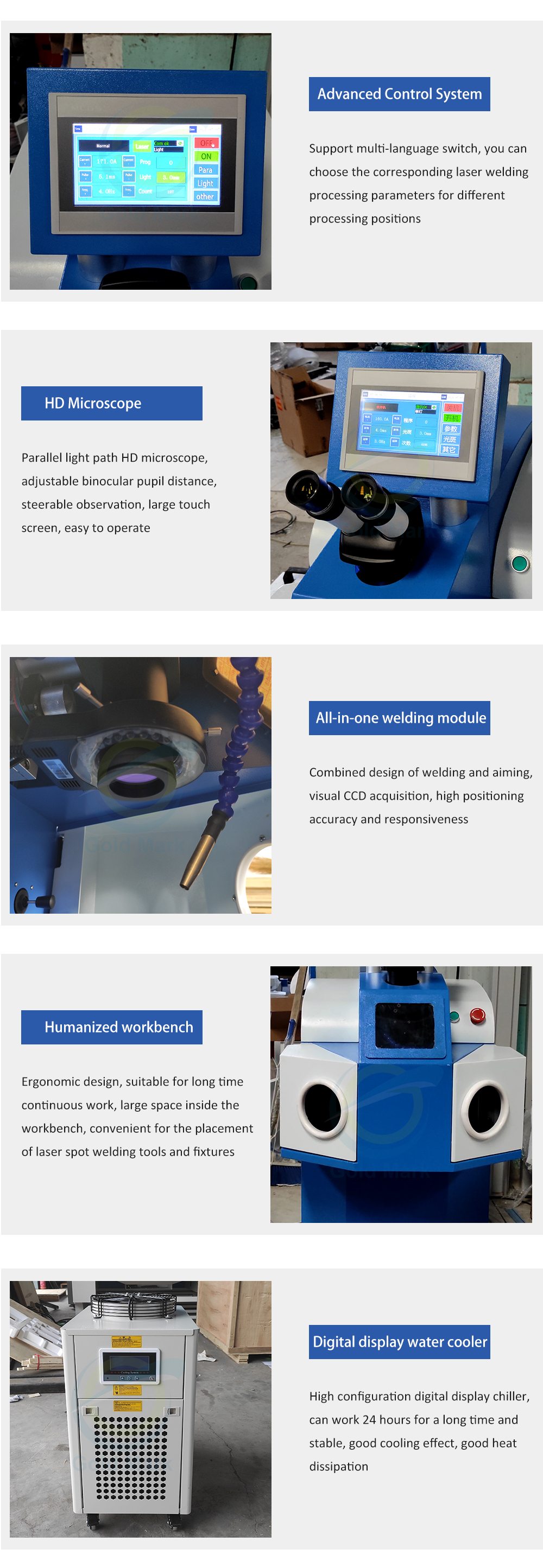

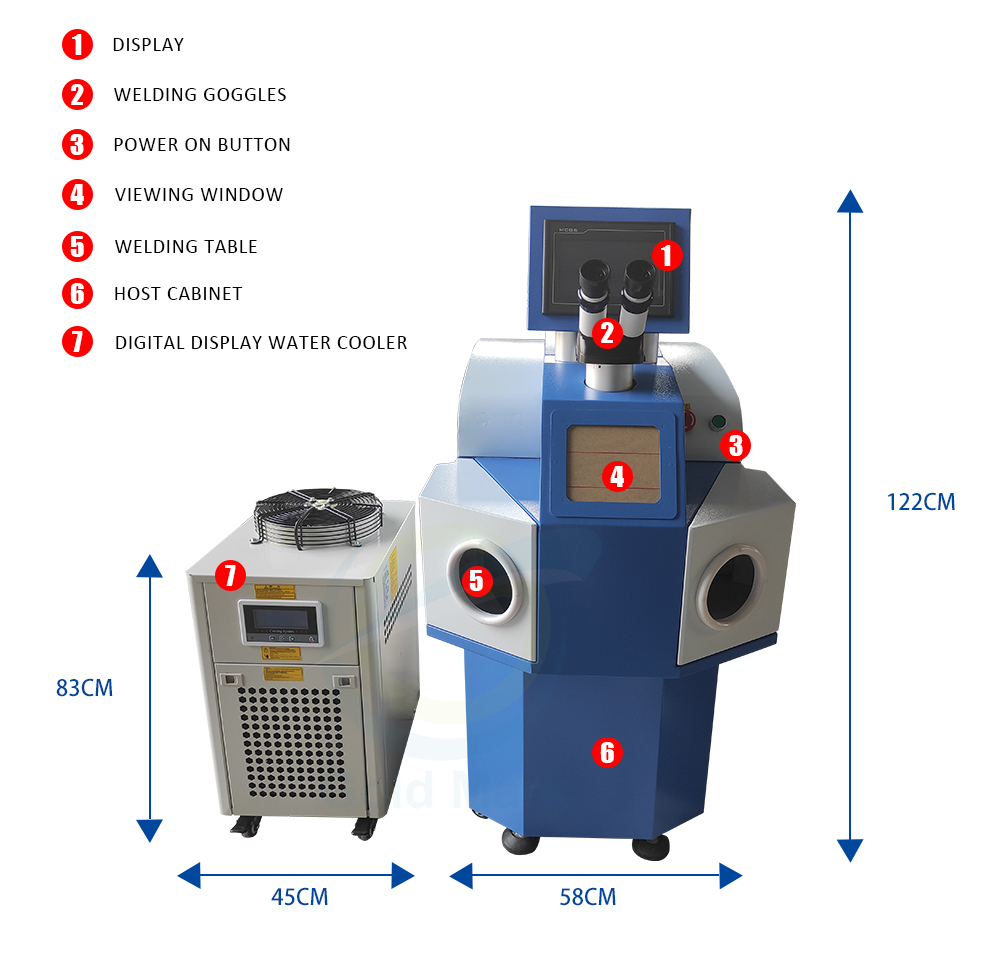

● Energy, pulse width, frequency, spot size, etc. can be adjusted in a wide range to achieve a variety of welding effects. Parameters are adjusted by the control lever inside the closed cavity, simple and easy to operate .

● Adopting British imported ceramic spotting cavity, corrosion resistant, high temperature resistant, high photoelectric conversion efficiency, spotting cavity life (8-10 years), xenon lamp life over 8 million times.

● Adopt the world’s advanced automatic shading system to avoid the stimulation of eyes during working hours.

● With 24-hour continuous working capability, the whole machine has stable working performance and is maintenance-free within 10000 hours.

● Humanized design, ergonomic, long working hours without fatigue.