200w Fiber Laser Clean Metal Machine - 3000w fiber laser cutting machine TS-3015 for sheet metal – Gold Mark Detail:

Advantage of Fiber laser cutting machine:

1. Moving crossbeam, imported high precision racks and linear guide rail, stable transmission, high precision.

2. Machine frame, crossbeam and worktable adopt integral welding structure.

3. X, Y and Z axes use imported Japan servo motor with high precision and speed.

4. Using professional and powerful Shanghai Cypcut fiber cutting controlling system that based on Windows

operating system, with good Human Machine Interaction and easy operation.

5. Laser is produced without gas and it could use air to cut sheet metal.

Wide range of applications

Fiber laser cutting machine is mainly used for fast cutting of carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, stuffed washboard, aluminum zinc plated sheet and many other metal materials. Fiber laser cutting machine is used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, machinery, precision parts, ships, metallurgical equipment, elevators, kitchenware, household appliances, crafts and gifts, tool processing, decoration, advertising, metal external processing and other various manufacturing and processing industries.

product parameters

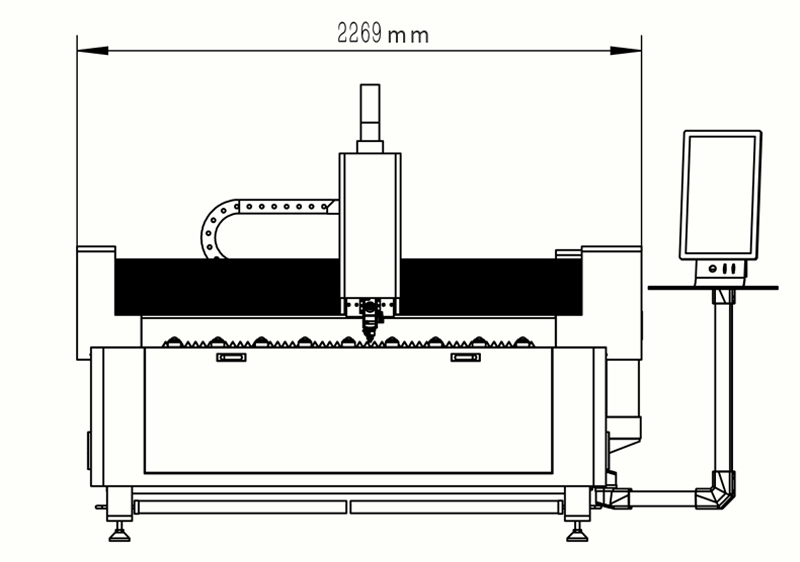

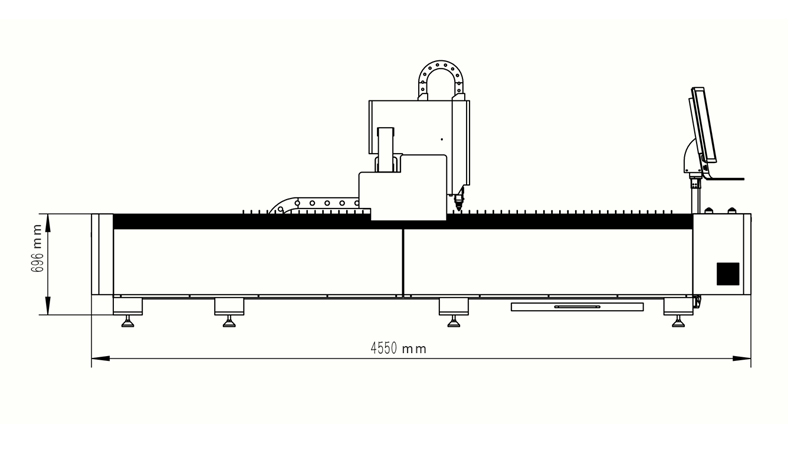

Specification:

| Model | TS-3015 |

| Dimension | 4600*2450*1700mm |

| Laser power | 3KW |

| Working area for metal sheet | 3000*1500mm |

| Y-axis stroke | 3000mm |

| X-axis stroke | 1500mm |

| Z-axis stroke | 120mm |

| X/Y axis position accuracy |

±0.03mm |

| X/Y axis reposition accuracy | ±0.02mm |

| Max. Moving speed | 80m/min |

| Maximum acceleration | 1.0G |

| Max. Working capacity of sheet table | 900kg |

| Specified voltage and frequency | 380V/50Hz/60Hz/60A |

| Continuous working time | 24h |

Main components:

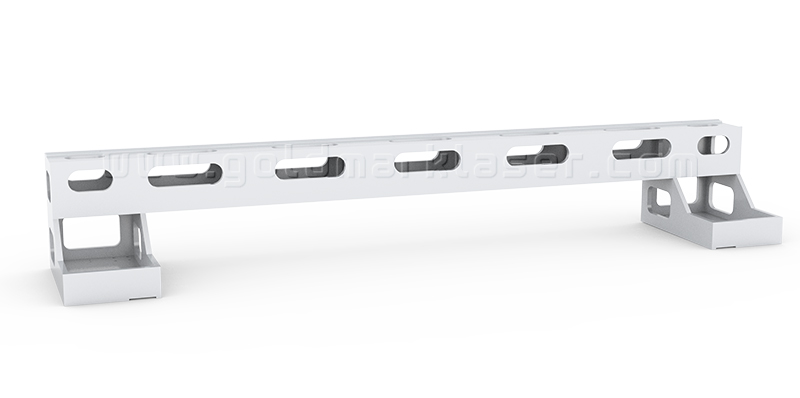

Fiber laser cutting machine bed:

Excellent lubrication performance and lower themal sensitivity,higher strength and hardness.

Greatly reduce equipment use loss and machine bed vibration processing error,machine tool accuracry will be manintained for a long time,unchanged for 50 years.

Fiber laser cutting machine Crossbar:

Adopting aerospace standard manufacturing aviation aluminum, the beam is hard, light, anti-corrosion, anti-oxidation, low density, and greatly improve the processing speed.

Sample Show:

Fiber laser cutting machine can be used to process materials: stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum,

aluminum alloy, galvanized plate, aluminum zinc plate, pickled plate, copper, silver, gold, titanium and other metal plates and tubes cutting.

Machine Show:

Product Process

Milling machine mill fiber machine guide rails and machine gantry and machine body. This way let machine has higher precision and machine working more stable when machine working

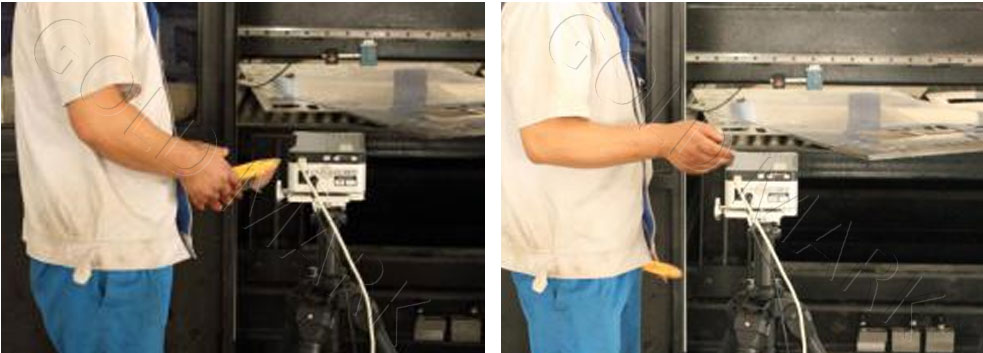

This is Laser interferometer for testing machine precision and using this Laser inte- rferometer to improve machine precision carefully. only few companies in China use this Laser interferometer to test machine precision. In Jinan only our company use Laser interferometer to test machine precision.

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for 200w Fiber Laser Clean Metal Machine - 3000w fiber laser cutting machine TS-3015 for sheet metal – Gold Mark, The product will supply to all over the world, such as: Canada, Romania, Sacramento, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.