Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for High Quality China Max Laser Cutter 1000W 2000W 3000W High Precision Fiber Laser Cutting Machine 3015 Cutting Area, Honesty is our principle, skilled procedure is our perform, service is our target, and customers’ satisfaction is our long term!

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for China Laser, Cutting Machine, As operation principle is “be market-oriented , good faith as principle, win-win as objective”, holding on “customer first, quality assurance, service first” as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

Advantage of Fiber laser cutting machine:

1. Moving crossbeam, imported high precision racks and linear guide rail, stable transmission, high precision.

2. Machine frame, crossbeam and worktable adopt integral welding structure.

3. X, Y and Z axes use imported Japan servo motor with high precision and speed.

4. Using professional and powerful Shanghai Cypcut fiber cutting controlling system that based on Windows

operating system, with good Human Machine Interaction and easy operation.

5. Laser is produced without gas and it could use air to cut sheet metal.

Specification:

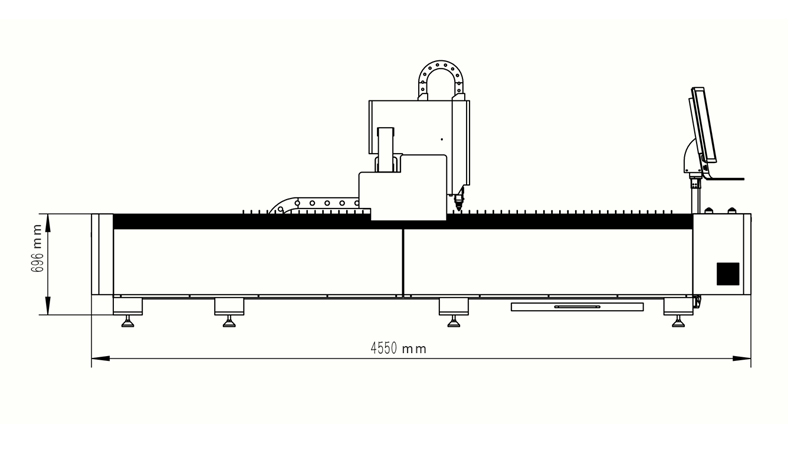

| Model | TS-3015 |

| Dimension | 4600*2450*1700mm |

| Laser power | 1KW |

| Working area for metal sheet | 3000*1500mm |

| Y-axis stroke | 3000mm |

| X-axis stroke | 1500mm |

| Z-axis stroke | 120mm |

| X/Y axis position accuracy |

±0.03mm |

| X/Y axis reposition accuracy | ±0.02mm |

| Max. Moving speed | 80m/min |

| Maximum acceleration | 1.0G |

| Max. Working capacity of sheet table | 900kg |

| Specified voltage and frequency | 380V/50Hz/60Hz/60A |

| Continuous working time | 24h |

Main components:

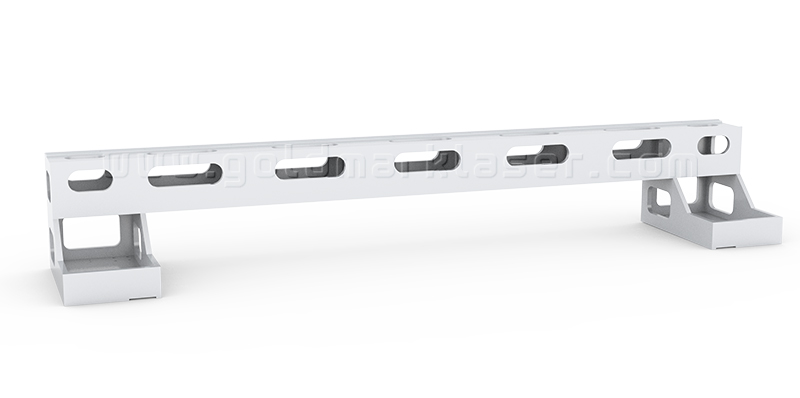

Fiber laser cutting machine bed:

Excellent lubrication performance and lower themal sensitivity,higher strength and hardness.

Greatly reduce equipment use loss and machine bed vibration processing error,machine tool accuracry will be manintained for a long time,unchanged for 50 years.

Fiber laser cutting machine Crossbar:

Adopting aerospace standard manufacturing aviation aluminum, the beam is hard, light, anti-corrosion, anti-oxidation, low density, and greatly improve the processing speed.

Sample Show:

Fiber laser cutting machine can be used to process materials: stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum,

aluminum alloy, galvanized plate, aluminum zinc plate, pickled plate, copper, silver, gold, titanium and other metal plates and tubes cutting.

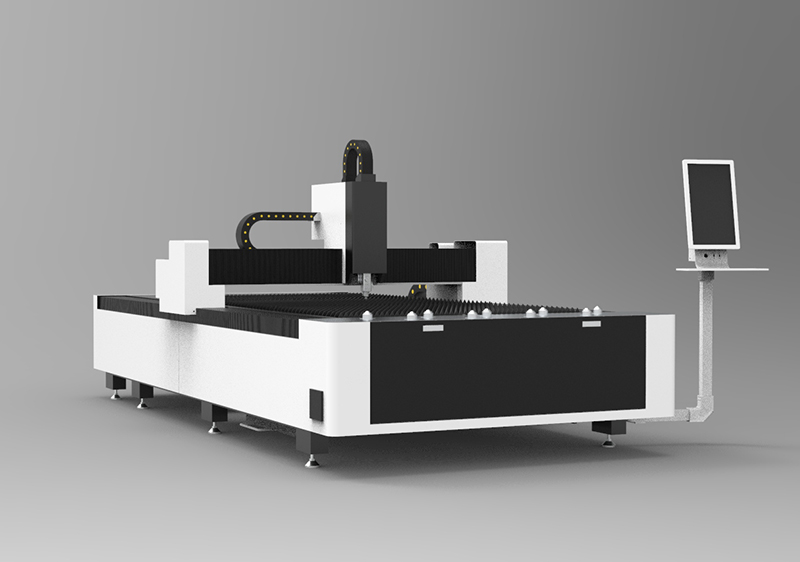

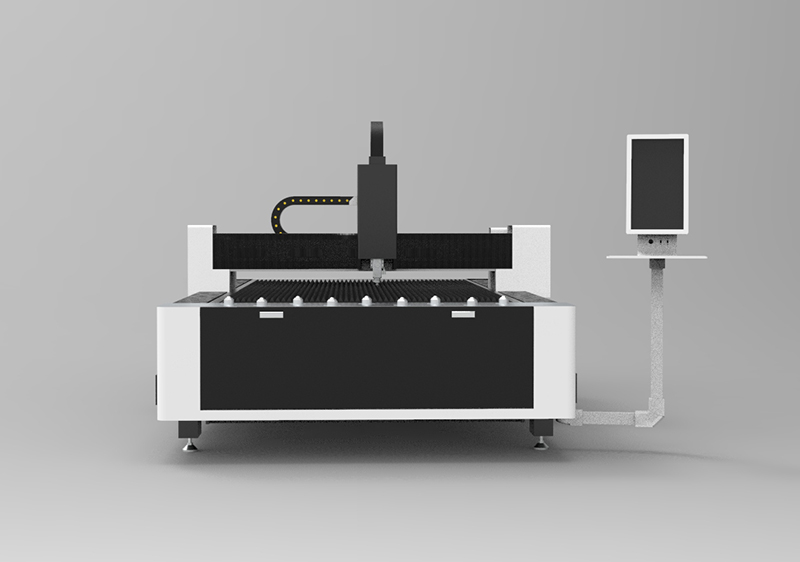

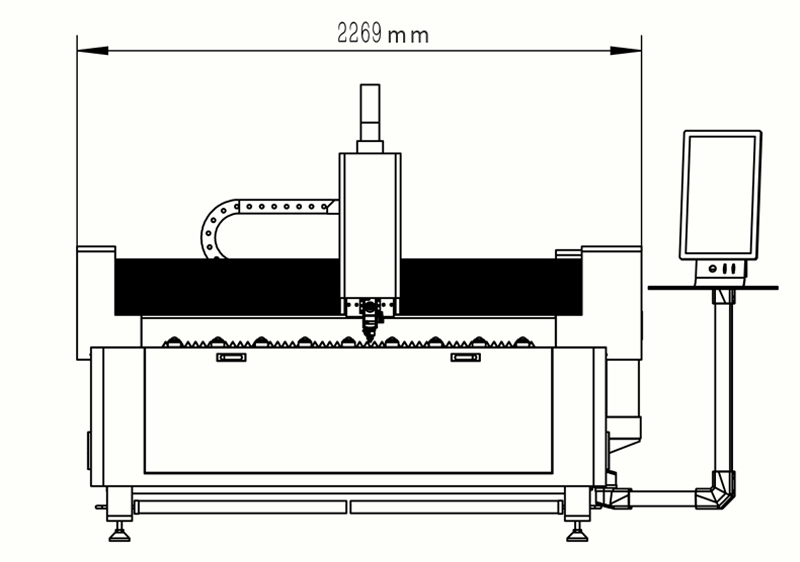

Machine Show: