Product Description

Plasma txiav tshuab nrog ob sab tsav, ruaj khov, kev teeb tsa zoo thiab kev ua haujlwm siab, tuaj yeem siv rau loj, nruab nrab thiab me steel phaj kos strips nyob rau hauv ntau yam carbon steel, manganese steel thiab lwm yam ntaub ntawv hlau.Nws tuaj yeem teeb tsa nrog ntau lub teeb hluav taws xob raws li cov neeg siv khoom xav tau, thiab tuaj yeem teeb tsa nrog CNC zoo li lub teeb teeb raws li qhov xav tau, nrog kev xaiv cov nplaim hluav taws xob tsis siv neeg qhov siab hloov kho.

Khoom nta

Plasma tej tshuab kev loj hlob mus rau tam sim no, cov roj ua hauj lwm yuav siv tau (ua hauj lwm roj yog cov plasma arc conductive nruab nrab, tab sis kuj lub tshav kub nqa lub cev, tab sis kuj yuav tshem tawm cov molten hlau nyob rau hauv lub incision) ntawm cov yam ntxwv ntawm cov plasma. arc thiab txiav zoo, ceev muaj qhov cuam tshuam loj.Feem ntau siv plasma arc ua haujlwm gases yog argon, hydrogen, nitrogen, oxygen, cua, dej vapor thiab qee cov roj sib tov.

Plasma tej tshuab yog dav siv nyob rau hauv ntau yam industries xws li tsheb, locomotive, siab hlab ntsha, tshuaj machinery, nuclear kev lag luam, dav machinery, engineering machinery thiab steel lug!Kev nyab xeeb, yooj yim, zoo, ntau yam thiab ib puag ncig tus phooj ywg txoj kev thermal ua (txiav, vuam, brazing, quenching, txau, thiab lwm yam) ntawm cov hlau los ntawm 0.3 hli tuab los ntawm kev tau txais cov ntshav los ntawm cov dej vapor yog thawj zaug hauv keeb kwm. ntawm kev lag luam hlau.

Txoj cai ntawm kev ua haujlwm

Plasma yog cov pa roj uas kub kub heev thiab muaj ionised heev, nws hloov lub zog ntawm lub arc mus rau lub workpiece, lub siab kub ua rau lub workpiece yaj thiab raug tshuab tawm, ua rau lub xeev ua hauj lwm ntawm plasma arc txiav.Compressed cua nkag mus rau hauv lub teeb thiab muab faib los ntawm cov pa roj chamber nyob rau hauv ob txoj kev, piv txwv li los tsim cov plasma roj thiab cov auxiliary gas.Lub plasma arc ua hauj lwm rau yaj cov hlau, thaum lub auxiliary gas cools lub teeb Cheebtsam thiab tshuab los ntawm melted hlau.Kev txiav fais fab muaj ob ntu: lub ntsiab Circuit Court thiab tswj Circuit Court.Lub hauv paus ntsiab lus ntawm hluav taws xob: lub ntsiab Circuit Court muaj ib tug contactor, ib tug peb-theem fais fab transformer nrog siab toughness, peb-theem choj rectifier, ib tug high-frequency arc-directing coil thiab tiv thaiv Cheebtsam.Lub siab toughness tsis kam yog coj mus rau hauv tus yam ntxwv sab nraud ntawm cov khoom siv fais fab.Kev tswj Circuit Court yog ua tiav los ntawm lub laub-khawm hloov ntawm lub teeb rau tag nrho cov txheej txheem txiav: ua ntej qhov cua - lub hauv paus hluav taws xob hluav taws xob - kev pib arc siab - kev txiav - arc so - nres.Lub hwj chim mov rau lub ntsiab Circuit Court yog tswj los ntawm ib tug contactor;cov roj ntws yog tswj los ntawm lub solenoid valve;tswj Circuit Court tswj lub siab zaus oscillator kom ignite lub arc thiab nres lub siab zaus tom qab lub arc tau tsim.

Khoom parameters

| Qauv | 1530 63APlasma tej tshuab (siab configuration) |

| X, Y cheeb tsam ua haujlwm | 1500 * 3000 hli |

| Z chaw ua haujlwm | 150 hli |

| Packing dimension | 2280mm * 3850mm * 1850mm |

| Tshuab dhos txaj | Heev tuab steel qauv |

| Tshuab fais fab | 16 kwv |

| Ua haujlwm voltage | 380V peb theem 60hz |

| Reposition precision | 0.02 hli |

| Ua precision | 0.1 hli |

| Qhov siab tshaj plaws txiav ceev | 12000mm / min |

| Torch Qhov siab tswj hom | Tsis siv neeg |

| Txiav thickness | Max 12 hli carbon steel |

| Plasma fais fab mov | LGK63A |

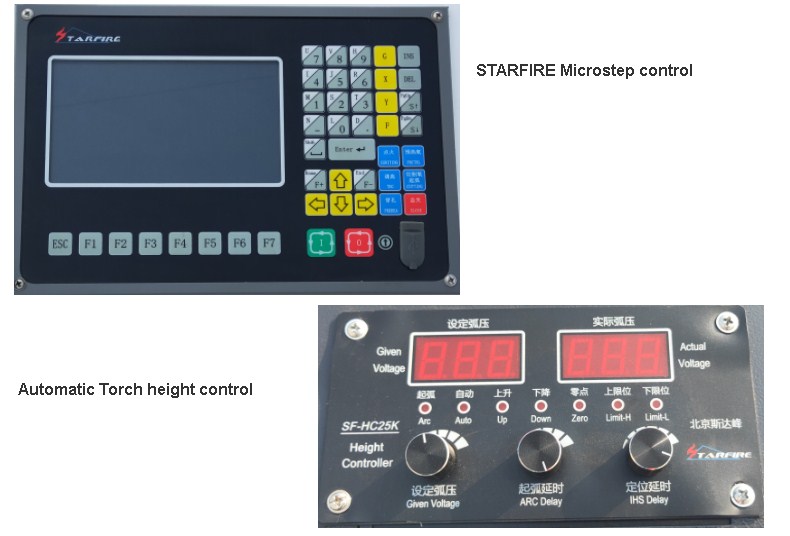

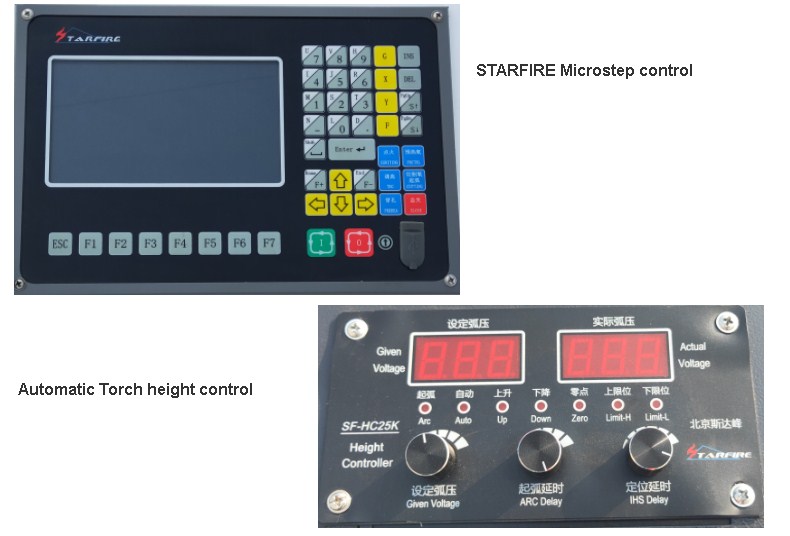

| Tswj qhov system | STARfire |

| Lub cev muaj zog | Stepper lub cev muaj zog |

| Software | Starcam |

| Qhov hnyav | 1600 KG |

| Plasma Cua Siab | Qhov siab tshaj 0.8 Mpa |

| Ua haujlwm kub | -10 ° C - 60 ° C.Tus txheeb ze humidity, 0-95%. |

| LCD Zaub Dimension | 7 nti |

Cov ntsiab lus ntawm cov khoom

Cov ntaub ntawv siv tau

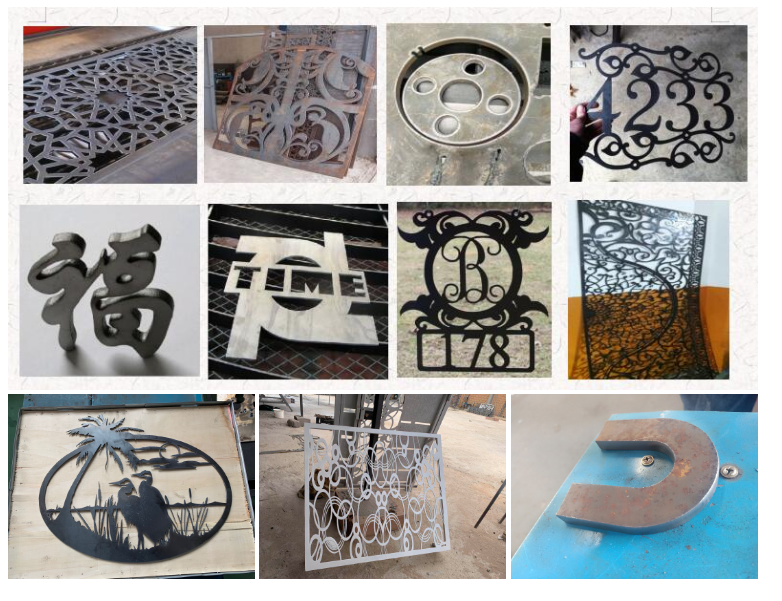

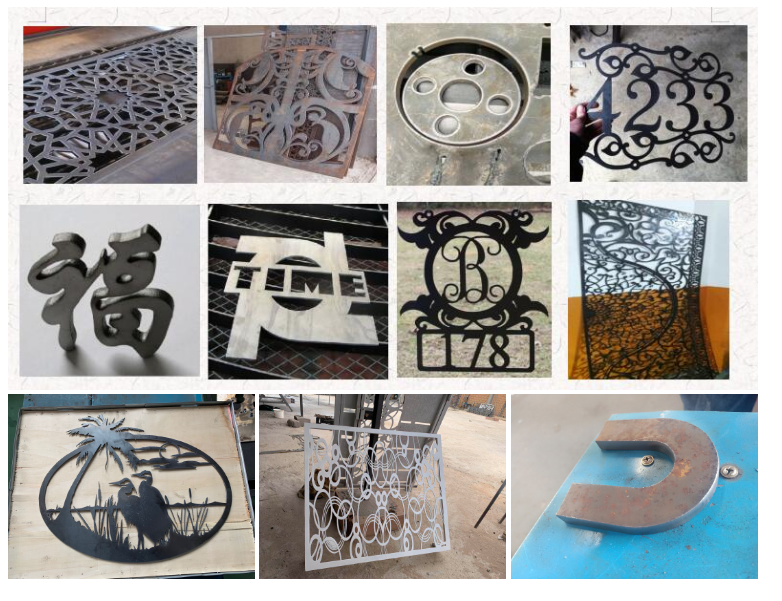

To plasma txiav tshuab1530, nws txiav tag nrho cov hlau, suav nrog tab sis tsis txwv rau txhuas ntawv, hlau ntawv, galvanized (steel) ntawv, me me hlau, titanium ntawv, stainless hlau, hlau thiab lwm yam.

Muaj kev lag luam

Kev lag luam tshaj tawm: Kev tshaj tawm cov paib, cim logo, cov khoom siv kho kom zoo nkauj, kev tsim cov ntawv tshaj tawm thiab ntau yam khoom siv hlau.

Pwm Kev Lag Luam: Engraving hlau pwm ua los ntawm tooj liab, txhuas, hlau thiab lwm yam.

Kev lag luam hlau: Rau steel, Carbon Steel, Stainless hlau, alloy steel, caij nplooj ntoos hlav steel, tooj liab phaj, txhuas phaj, kub, nyiaj, Titanium thiab lwm yam hlau phaj thiab raj.

Tshuab duab

Factory thiab shipping duab