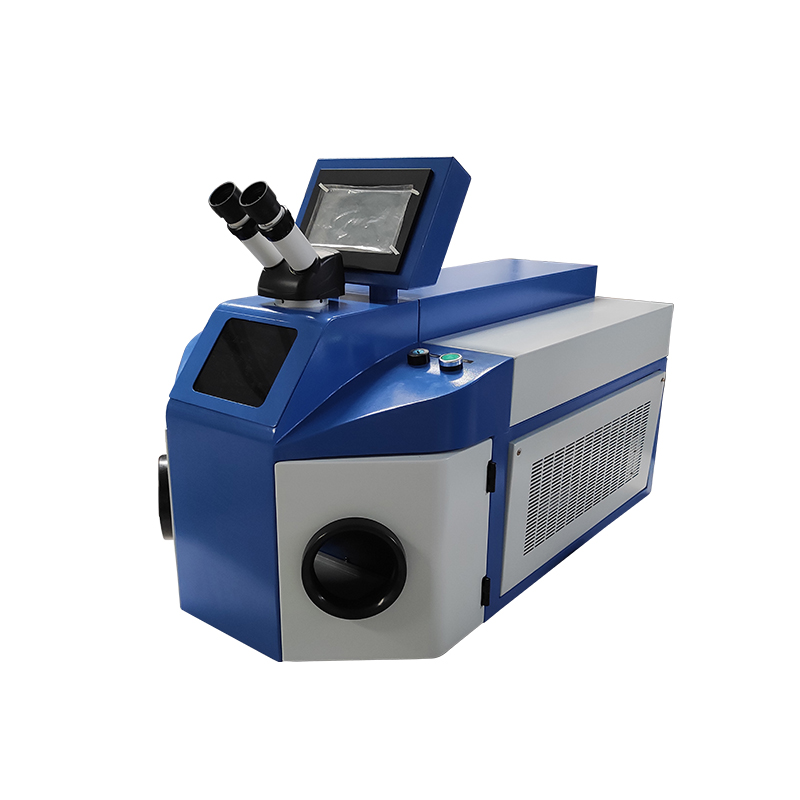

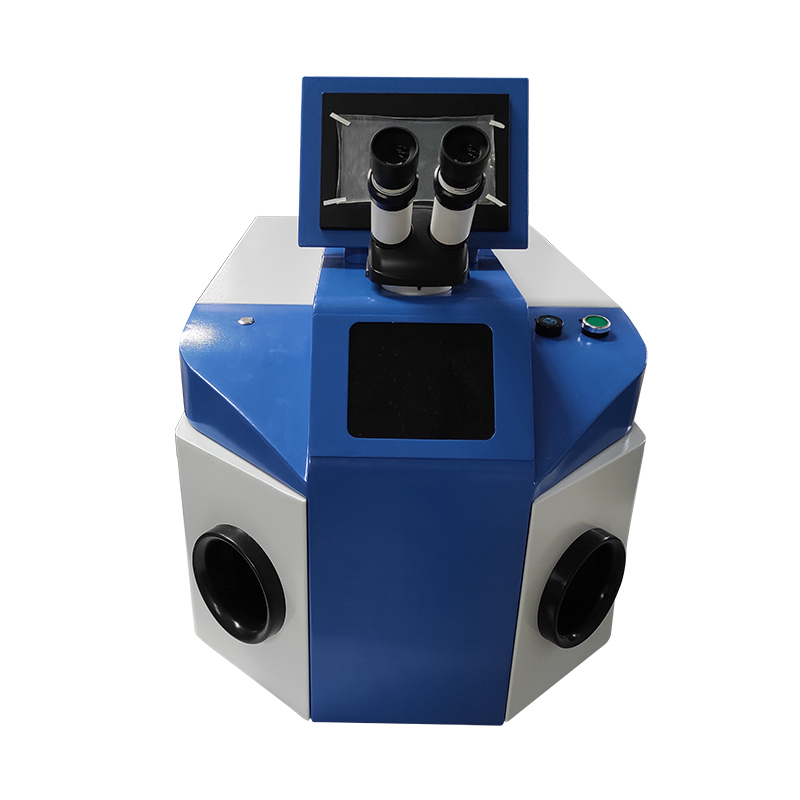

Laser Welding Machine For Metal1500w - Desktop jewellery soldering machine – Gold Mark Detail:

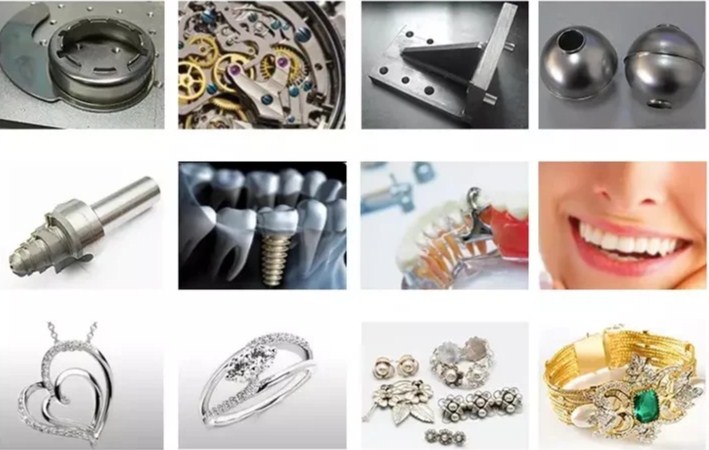

The desktop jewellery laser spot welding machine is a professional laser equipment for metal welding in the jewellery industry, mainly used for filling holes, spot welding trachoma and repair welding of gold and silver jewellery. It has the advantages of high precision, low loss and super fast, mainly used for filling holes, spot welding trachoma and repair welding of gold and silver jewellery, suitable for gold, silver, platinum, stainless steel, titanium and other heavy metals and their alloy materials, also can be used for filling trachoma of dentures and tiny precision devices such as battery nickel tape, integrated circuit leads, clock and watch filaments, picture tubes, electronic gun assembly and other fields of welding.

Product features

● Equipped with Chaomi Laser’s automatically developed voltage regulated pulse power supply, which is compact in size and has 15% more energy per pulse than ordinary power supplies. It is more suitable for the welding of gold, silver and other highly reflective materials.

● The core component “laser cavity” is a gold-plated reflective cavity, which provides more stable performance and longer service life, providing users with efficient and economical processing solutions.

● The machine’s structure is optimised for compactness and portability, making it a true high-performance mini-welding machine.

● High welding quality and beautiful weld seam, the weld seam can be of the same strength as the base material without secondary processing, effectively improving the qualification rate of the finished product.

● Can weld refractory materials, especially suitable for precision welding of micro and small parts and jewellery.

● Highly customisable, the machine can be tailor-made to meet customer requirements.

Product parameters

|

Model

|

LM-200 Laser Welding Machine

|

|

Output Power

|

100 W I 200 W I 300 W – based on requirement

|

|

Single-pulse energy

|

0-100 J

|

|

Machine Design Type

|

Desktop I Vertical

|

|

Laser Source

|

ND: YAG

|

|

Laser Wavelength

|

1064 nm

|

|

Pump lamp

|

Pulsed Xenon Lamp

|

|

Pulse Width

|

0.1.15 ms adjustable

|

|

Pulse Repeated Frequency

|

1 – 20 Hz adjustable

|

|

Welding spot diameter

|

0.2-1.5 mm adjustable

|

|

Observing System

|

Microscope I CCD – based on requirement

|

|

Cooling System

|

Water chiller

|

|

Power Supply

|

Single Phase AC 220V ± 10%, 50Hz I 60HZ, 4 KW

|

|

Running Environment

|

Temperature 5°C-28°C Humidity 5%-70%

|

Sample Show

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Value and Efficient Service" for Laser Welding Machine For Metal1500w - Desktop jewellery soldering machine – Gold Mark, The product will supply to all over the world, such as: Moscow, Zambia, Bangladesh, Our items are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!