Metal steel aluminum alloy round tube stainless steel automatic spot welding laser welding machine

Our improvement depends on the highly developed gear ,outstanding talents and repeatedly strengthened technology forces for New Arrival China China Handheld Fiber Laser Welder 1000W 1500W 2000W Stainless Steel Laser Welding Machine, As a leading manufacture and exporter, we take pleasure in a great name in the international markets, especially in America and Europe, because of our top quality and realistic charges.

Our improvement depends on the highly developed gear ,outstanding talents and repeatedly strengthened technology forces for China Laser Welding Equipment, Metal Laser Welder, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our merchandise, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

|

NO. |

Name |

Parameter |

|

1 |

Machine model |

Hand-held fiber laser welding machine |

|

2 |

Laser source |

Raycus |

|

3 |

laser power |

1000W、1500W、 |

|

4 |

laser wave length |

1070 NM |

|

5 |

Uptime |

24 hours |

|

6 |

operate mode |

continuation/ modulate |

|

7 |

Welding speed range |

0~120 mm/s |

|

8 |

Laser pulse width |

0.1-20ms |

|

9 |

Cooling chiller |

Industrial water chiller |

|

10 |

Working environment temperature range |

15~35 ℃ |

|

11 |

Humidity range of working environment |

< 70% No condensation |

|

12 |

Welding thickness recommendations |

0.5-3mm |

|

13 |

Welding gap requirements |

≤0.5mm |

|

14 |

working voltage |

220 V |

|

15 |

Dimensions |

1140*670*1400 mm |

|

16 |

Weight |

270kg |

Product Advantages

1. Handheld welding head is flexible and convenient, which can realize outdoor welding.

2. High welding efficiency, 2 to 10 times faster than conventional welding.

3. The operation mode of the handheld torch enables the workpiece to be welded at any angle in any part.

4. It is suitable for spot welding of various complex welded joints and various equipment.

5. Compared with traditional welding, the weld seam is flat and beautiful, with very few defects, deeper welding depth and smaller thermal stress deformation.

6. can be precisely controlled, with a small focused light point, which can be positioned with high precision and easily automated.

7. can realize the welding between some kind of dissimilar materials.

8. can realize spot welding, butt welding, stack seal welding, etc.

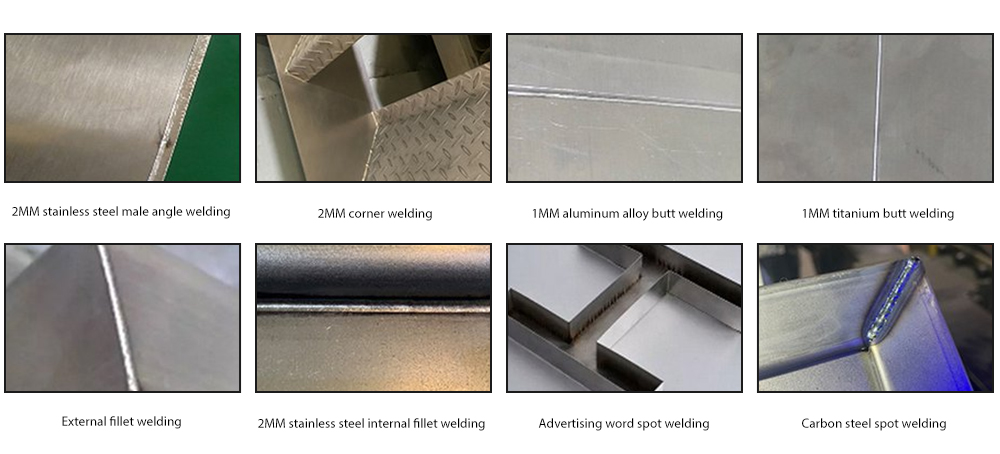

Weldable method

Sample Show

AFTER-SALE SERVICE

1.We have a professional and experienced after-sales team. We support door-to-door after-sales service. In order to effectivelysolve customer problems and help customers use the machine better, we will conduct skill assessments on our after-sales team every year.

2. We support e-mail, telephone, Wechat, Whatsapp, video and so on. As long as we can help you, you can choose the most convenient way you think

3. We support 2 years warranty,when you have any questions, you cancontact us anytime.