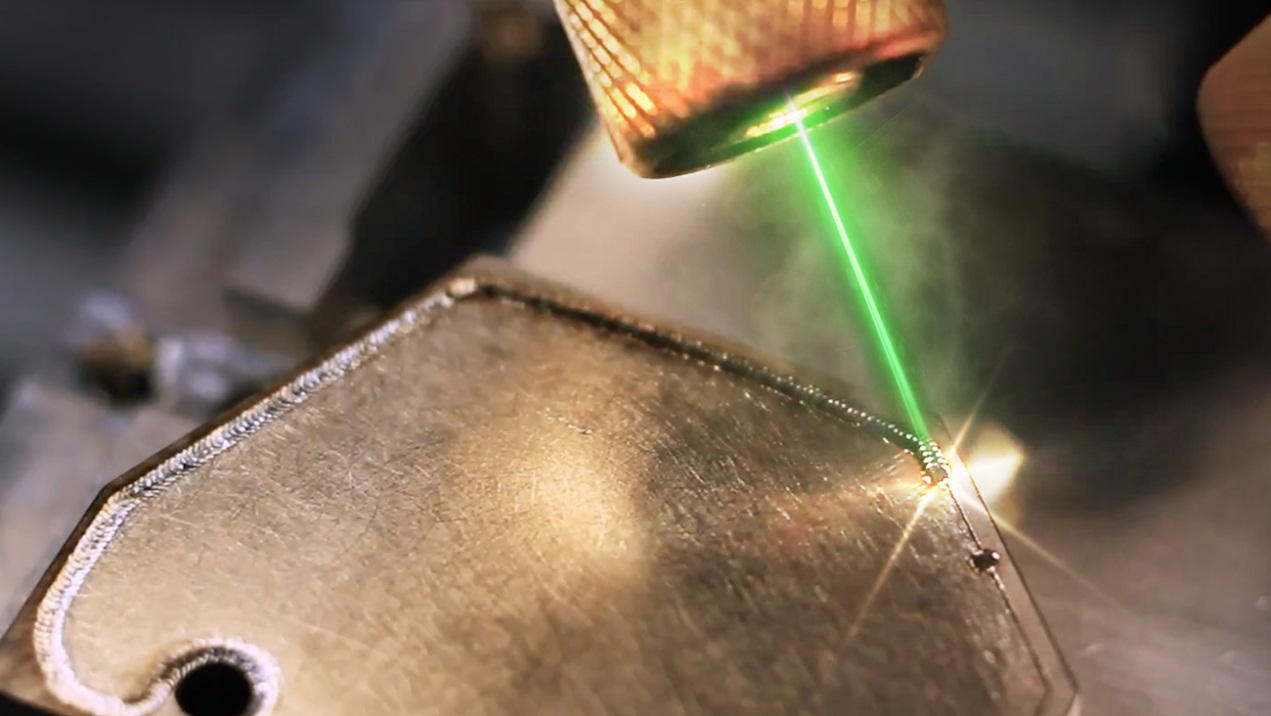

Laser welding machine as a new type of processing equipment, gradually replaced the traditional welding equipment, is widely used in various industries, in the process of using laser welding machine often encountered a variety of situations, for inexperienced friends, often overwhelmed do not know how to solve. In fact, there are some problems we can still solve themselves, so how to solve the common problems in the use of laser welding machine? The following follow the Gold Mark laser to see.

1 sputtering fire out of the pit.

1, the pressure is small, usually between 3-4 air pressure, according to the air pressure table on the spot welder shall prevail.

2, the buffer valve screwed outward counterclockwise to reduce the stroke of the buffer.

3, the pre-pressure moment is too short, adjust the pre-pressure moment, according to the length of the electrode stroke to adjust the pre-pressure moment, (pre-pressure moment is the electrode downward movement to the moment of pressing the workpiece discharge), the greater the stroke the longer the pre-pressure moment.

4, check whether the workpiece is rust, oil, if these two conditions idea disposal rust live oil;.

5, such as when welding wire, no oil or rust to check the appearance is not too much drawing powder.

2 the welding is not strong.

1, the current is too small or welding moment is too short, usually blood oxygen probe welding way to choose a short time high current welding, so that the best welding effect can be welded. According to the resolution of welding workpiece welding moment, usually welding moment grasp in 2-5 waves (50 waves per second, the conditions of the choice of this welding moment is not noisy load condition selection), welding moment is set after adjusting the welding current, the shorter the welding moment, the larger the welding current.

2, welding workpiece appearance of rust, oil, or pulling powder .

3, spot welding machine does not weld or no power: check the power line fuse, such as the fuse is not broken; check the circuit board to control the line is not a fallen appearance; check the controller fuse; spot welding machine has electricity, the controller is normal, does not work, check the foot switch, such as the foot switch is not a problem, check the foot switch connection line; spot welding machine operation is abnormal, step down the foot switch does not work, lift the foot switch work a little, check the foot switch; cylinder press down, not lift, check the cylinder and electrode slide rod connection is not loose fall; transformer all heat.

Jinan Gold Mark CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Post time: Apr-19-2021