Highly reactive materials to the laser, due to the absorption rate is not high, either cutting or welding is generally not very effective, resulting in poor stability of the processing process has been in the field of laser processing is the traditional problem, laser welding machine in the welding usually produces a higher degree of return than the cutting or longer duration of the phenomenon. So for the high anti- material, how to weld the best results, the following follow GOLD MARK to learn more.

When welding highly reflective materials such as aluminum and copper, different welding waveforms have a significant impact on weld quality. Using a laser waveform with a front spike can break through the high reflectivity barrier. The instantaneous high peak power can quickly change the state of the metal surface, causing the temperature to rise to the melting point, thus reducing the reflectivity of the metal surface and improving the utilization of energy. In addition, since materials such as copper and aluminum conduct heat quickly, the appearance of the solder joint can be optimized by using a slow-drop waveform.

On the other hand, the laser absorption rate of materials such as gold, silver, copper and steel decreases with increasing wavelength, and for copper, the absorption rate of copper is close to 40% when the laser wavelength is 532 nm.

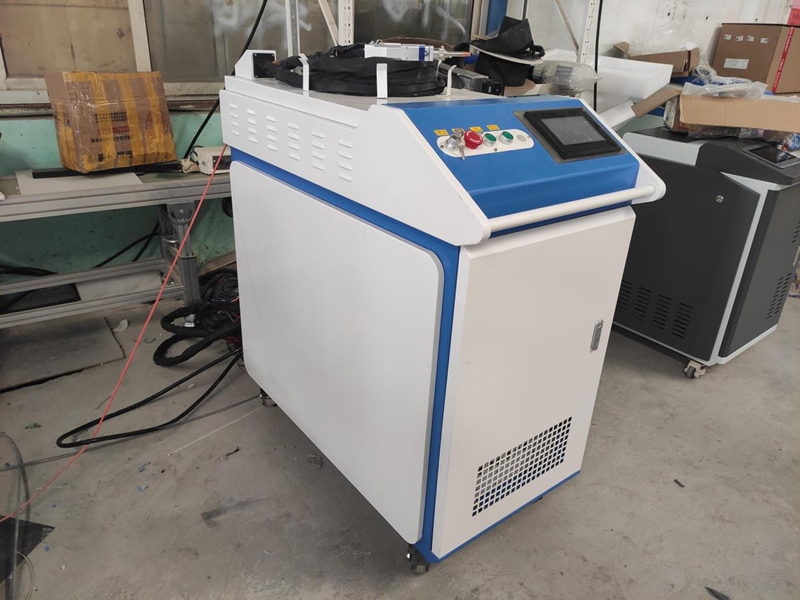

Jinan Gold Mark CNC Machinery Co., Ltd. is a high-tech industry enterprise specialized in researching, manufacturing and selling the machines as follows: Laser Engraver, Fiber Laser Marking Machine, CNC Router. The products have been widely used in advertisement board, crafts and molding, architecture, seal, label, woodcutting and engraving, stonework decoration, leather cutting, garment industries, and so on. On the base of absorbing the international advanced technology, we provide the clients the most advanced production and perfect after-sale service. In recently years, our products have been sold not only in China, but also as far as Southeast Asia, Middle east, Europe, South America and other overseas Markets.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Post time: Dec-21-2021