-

Advantages and welding process of optical fiber continuous automatic laser welding machine

The optical fiber continuous automatic laser welding machine not only realizes the welding of various metals, but also with the more distinctive products that various industries want to create, and the widespread application of equipment, the entire market has become active, not only for enterpri...Read more -

New 2022 handheld fibre laser welding machine back online

Two In One Welding Machine The so-called two in one means that the welding and cutting functions are owned at the same time. The main function is welding. When using the cutting function, you need to change the cutting head. As soon as the new product was launched, it was favored by new and old c...Read more -

Advantage analysis of handheld laser welding machine

There are many methods for metal welding, such as traditional argon arc welding, electric welding and other ordinary welding machines. In recent years, laser cutting and laser welding have entered the field of metal processing and forming. The hand-held laser welding machine has obvious advantage...Read more -

What is pulsed laser cleaning machine technology?

Laser cleaning technology uses high-frequency and high-energy laser pulses to irradiate the surface of the workpiece. The coating layer can instantly absorb the focused laser energy, so that the oil stains, rust spots or coatings on the surface can be evaporated or peeled instantly, and the surfa...Read more -

Analysis of the advantages of laser welding machine in the field of thin plate welding

Laser welding is one of the important components of laser material processing. Laser welding is a precision welding technology that uses a high-energy beam as a heat source. It mainly uses a high-energy laser beam to heat the surface of the workpiece, and the heat diffuses from the surface of the...Read more -

Laser welding machine application field and processing characteristics

With the rapid development of laser technology, laser application technology has become more and more widely used in fields such as automobiles, aerospace, defense industry, shipbuilding, marine engineering, nuclear power equipment, high-tech electronics, precision processing, and biomedicine. As...Read more -

What is pulsed laser cleaning machine technology?

Laser cleaning technology uses high-frequency and high-energy laser pulses to irradiate the surface of the workpiece. The coating layer can instantly absorb the focused laser energy, so that the oil stains, rust spots or coatings on the surface can be evaporated or peeled instantly, and the surfa...Read more -

New Product Preview

Recently, we have launched two new products, namely cleaning machine and two in one welding machine. Here are the details of the new product. Firstly,...Read more -

Advantages of the Qilin double pendulum handheld automatic wire feed laser welding machine

Two In One Welding Machine The so-called two in one means that the welding and cutting functions are owned at the same time. The main function is welding. When using the cutting function, you need to change the cutting head. As soon as the new product was launched, it was favored by new and old c...Read more -

Reasons for uneven laser marking effect

Laser marking technology has a variety of applications, such as fonts on computer keyboard keys, logo signs on household appliances, fonts on car keycaps and so on. The operator may often encounter uneven marking effect during processing, which may be the following problems: The machine level is...Read more -

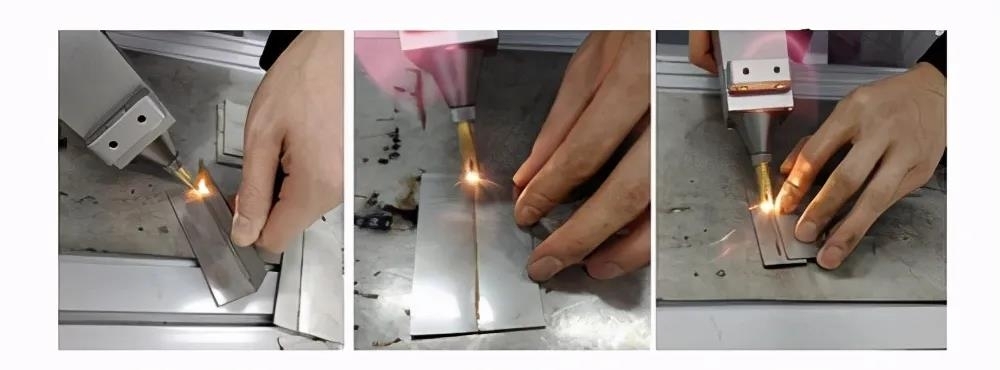

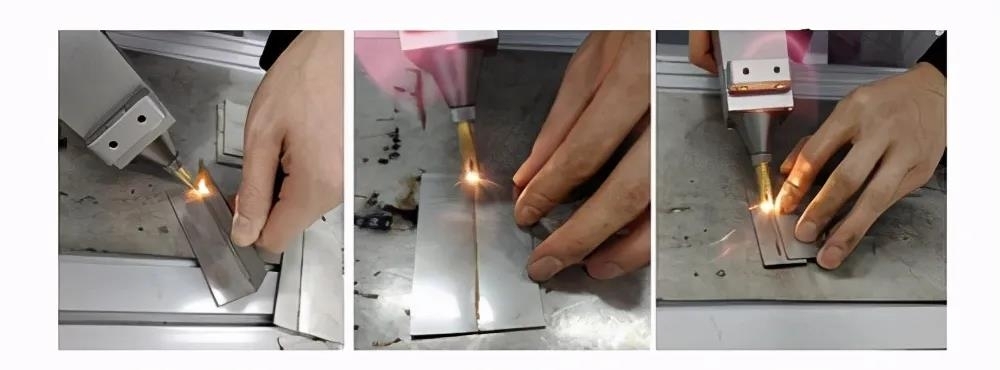

Advantages of handheld laser welding machine

Handheld laser welding machine is mainly applied to the fixed positions of large and medium-sized sheet metal, cabinet, chassis, aluminum alloy door and window frame, stainless steel wash basin and other large work pieces, such as inner right angle, outer right angle and plane weld welding. Duri...Read more -

Introduction to the features and applications of laser cleaners

The laser cleaning machine is mainly used to melt the rust, coating, oil and other surface substances on the product surface through the instantaneous high-temperature corrosion generated by the laser beam on the product surface. The high-energy density laser beam is used to irradiate the workpi...Read more -

Laser welding machine application field and processing characteristics

With the rapid development of laser technology, laser application technology has become more and more widely used in fields such as automobiles, aerospace, defense industry, shipbuilding, marine engineering, nuclear power equipment, high-tech electronics, precision processing, and biomedicine. A...Read more -

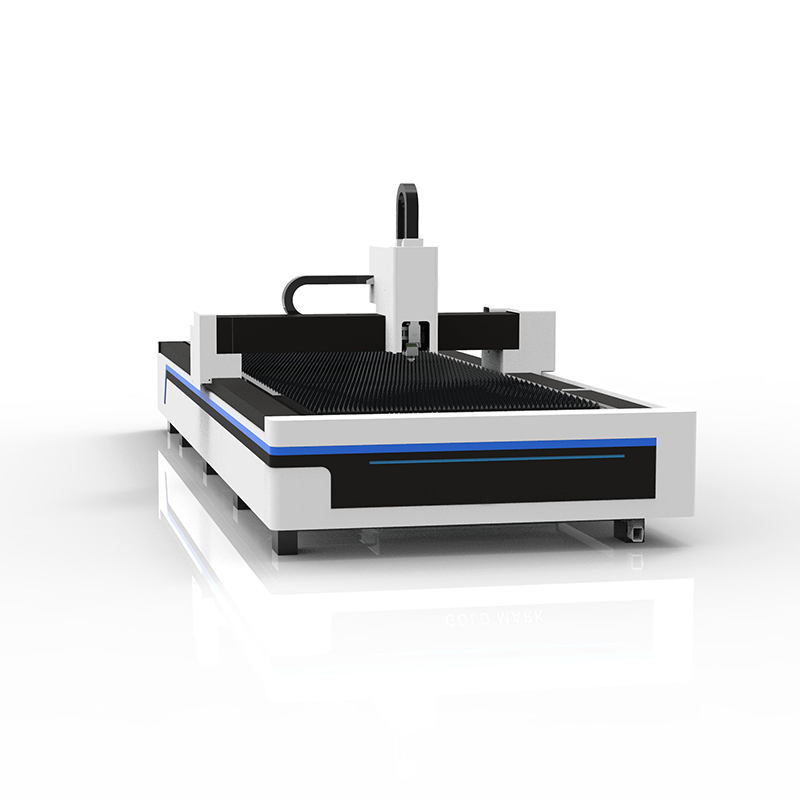

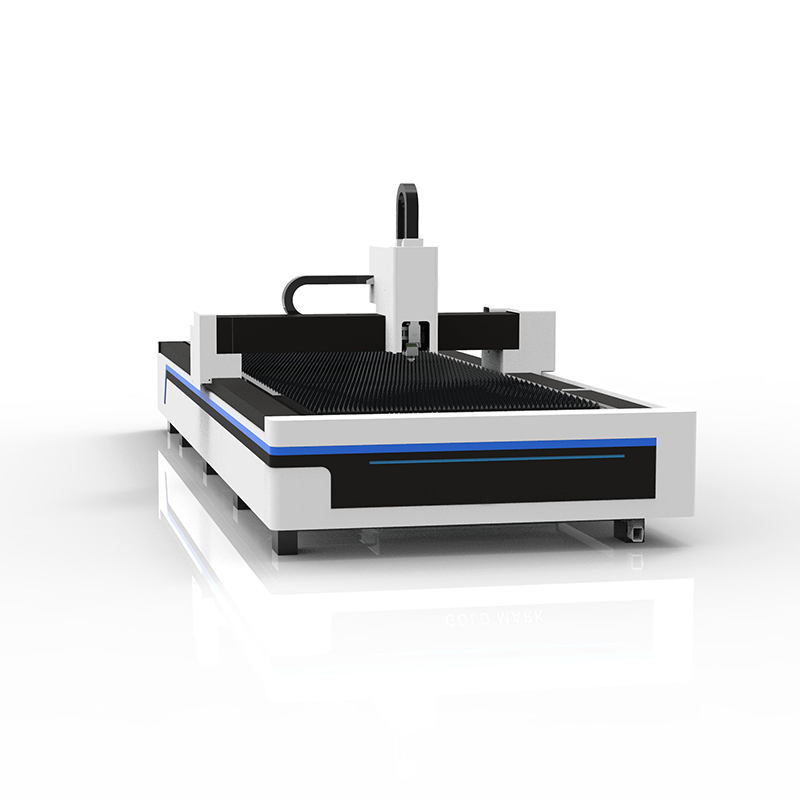

Advantages of laser cutting machine in electrical appliance manufacturing industry

Fiber Laser cutting machines are mainly used in the electrical industry to cut thin steel plate parts in the appearance of sheet metal parts and the installation of complete sets of electrical components. Nowadays, after adopting this new technology, many electrical appliance factories have impro...Read more -

Advantage analysis of handheld laser welding machine

In recent years, laser cutting and laser welding have entered the field of metal processing and forming. The hand-held laser welding machine has obvious advantages in efficiency and convenience, and has rapidly produced the “metal welding iteration effect”, which can almost replace ar...Read more -

What is pulsed laser cleaning machine technology?

Laser cleaning technology uses high-frequency and high-energy laser pulses to irradiate the surface of the workpiece. The coating layer can instantly absorb the focused laser energy, so that the oil stains, rust spots or coatings on the surface can be evaporated or peeled instantly, and the surfa...Read more