-

Laser engraving machine in the leather and textile industry, the application of engraving technology

Laser engraving machine is a kind of processing industry is more common CO2 laser equipment, widely used in a variety of non-metallic materials processing field. Laser engraving machine has the advantages of accurate processing, fast, simple operation, high degree of automation, can improve the e...Read more -

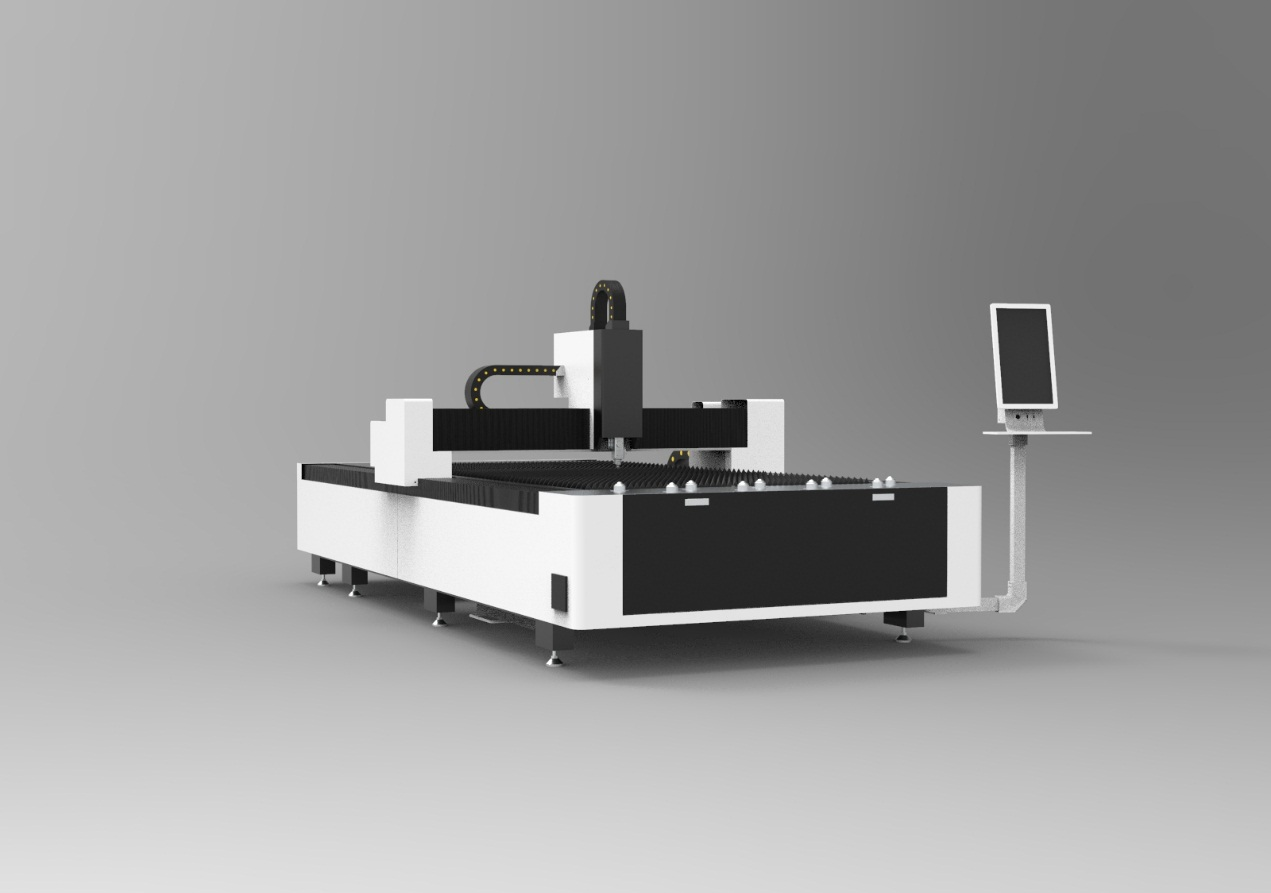

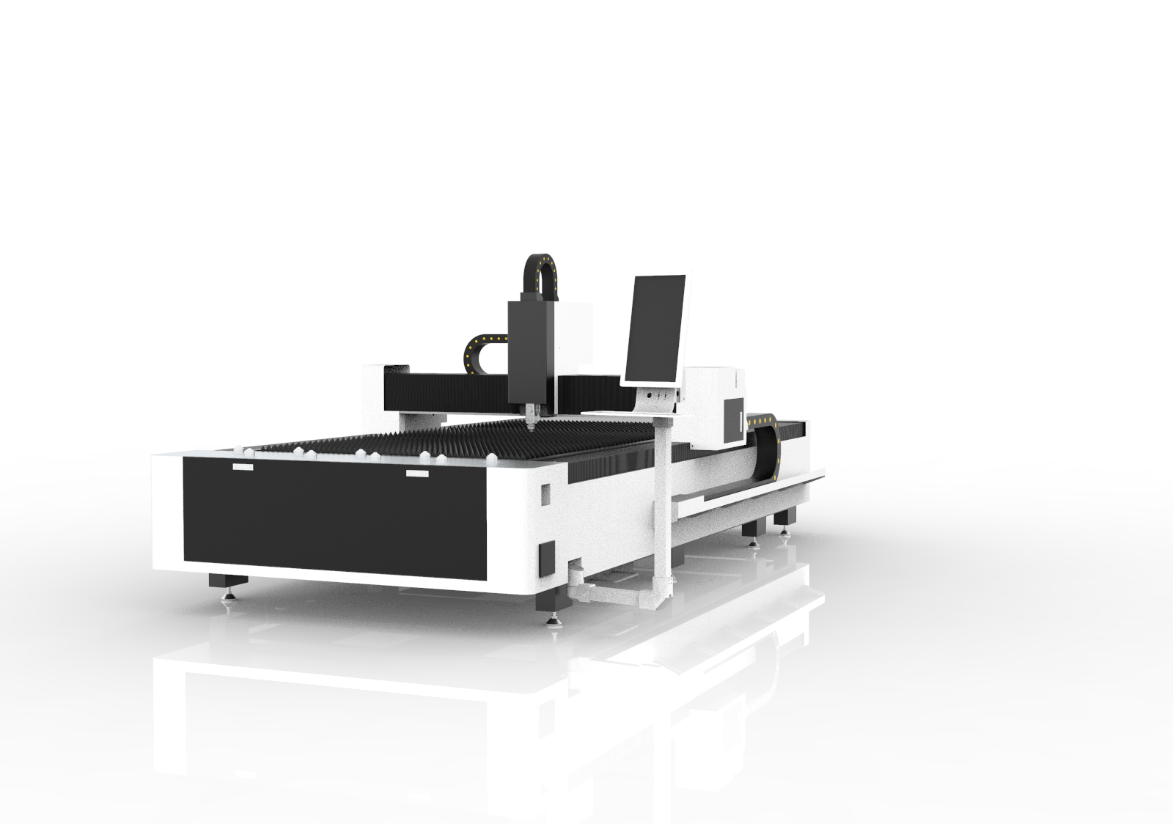

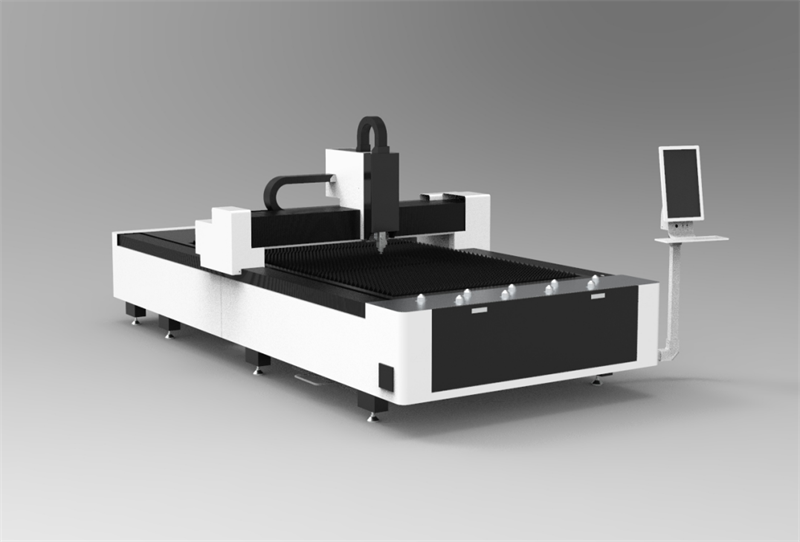

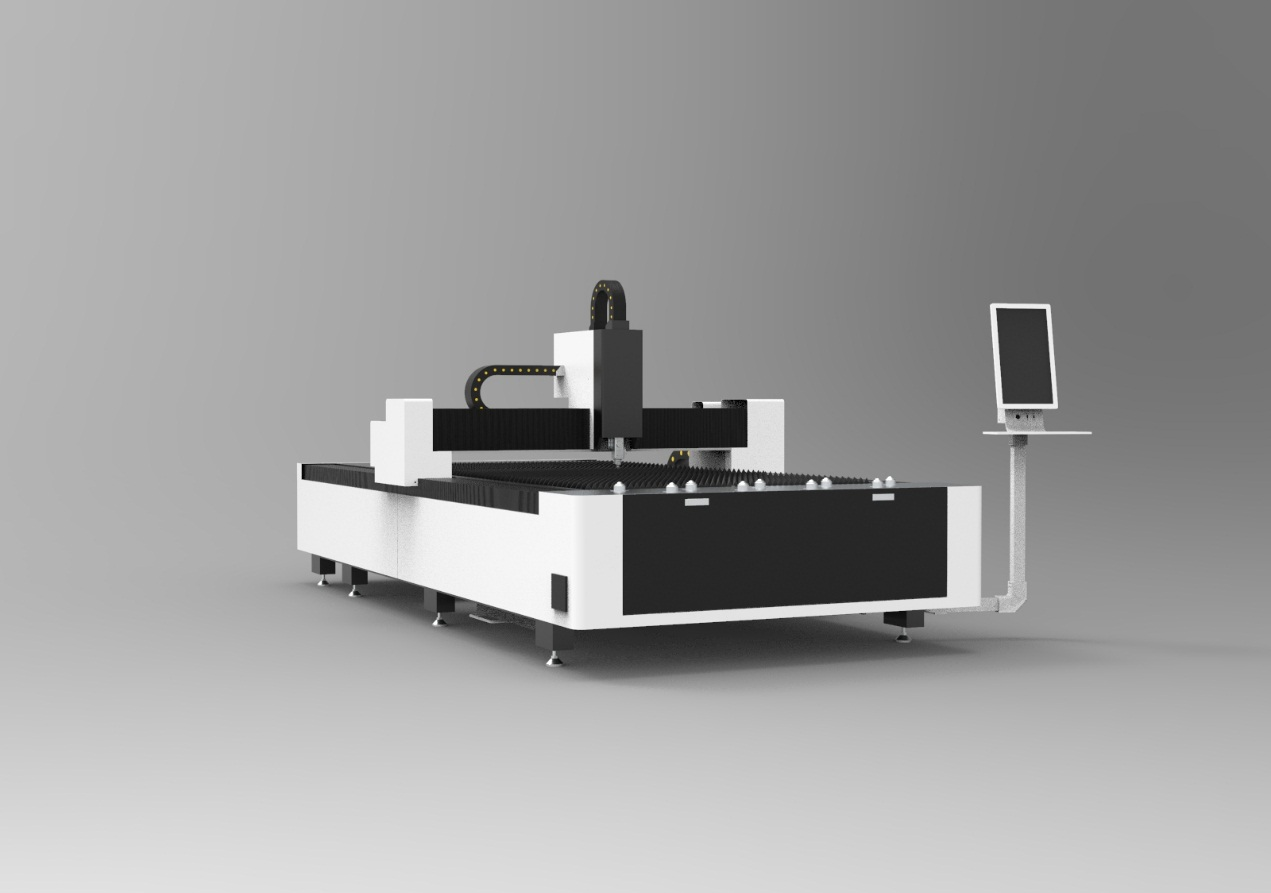

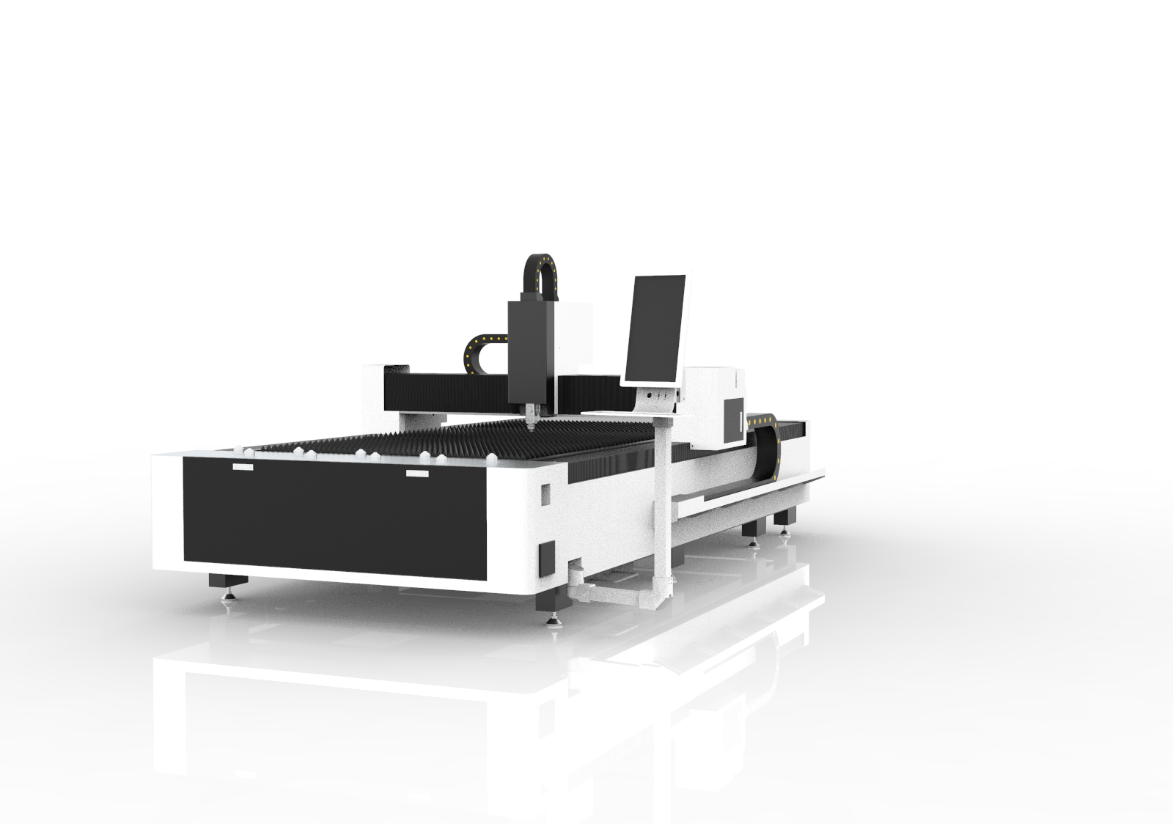

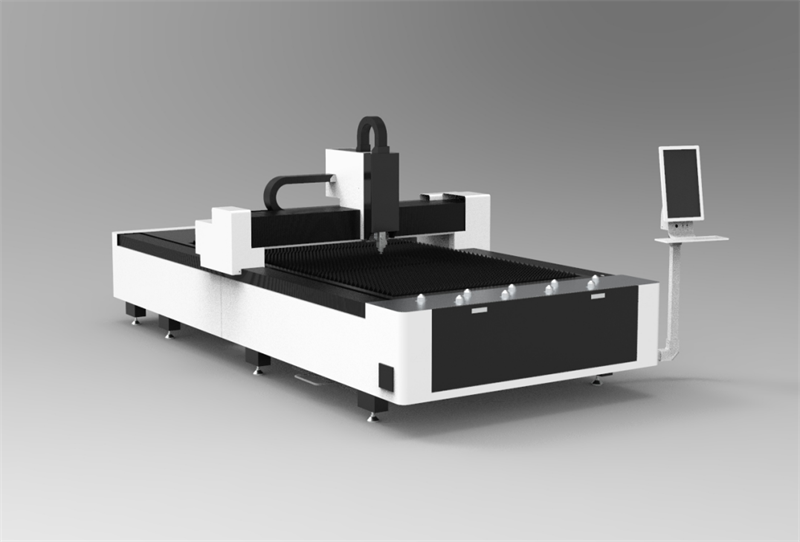

What are the advantages of the performance of fiber laser cutting machine

In the metal processing industry competition is increasingly fierce, fiber laser cutting machine has been the mainstream of the current metal processing industry equipment, whether in the cutting speed, or in the cutting quality, compared with other metal cutting equipment has absolute advantages...Read more -

Reveal why CO2 laser engraving machine can not engrave metal

Many friends are no stranger to laser engraving machine, usually laser engraving machine are applied to wood products, plexiglass, glass, stone, crystal, acrylic, paper, leather, resin and other materials. Some friends often have questions, why the laser engraving machine can not carve metal clas...Read more -

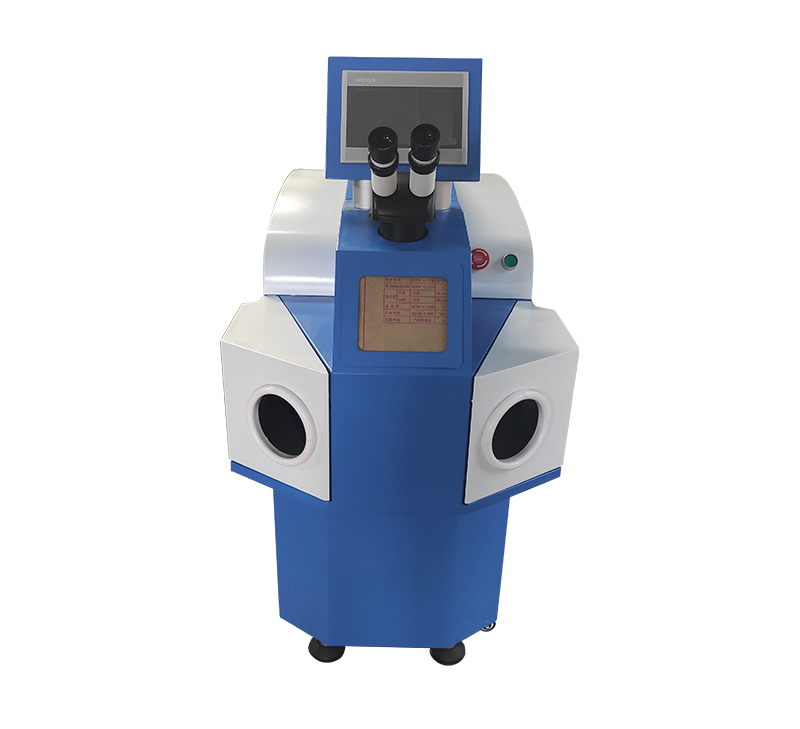

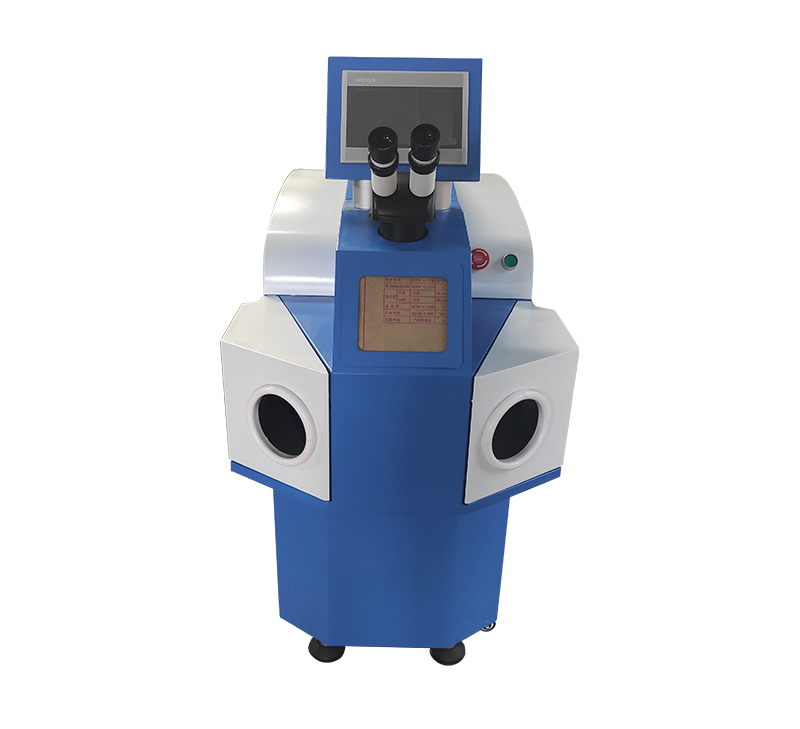

Laser welding machine welding metal effect how to determine

Laser welding machine as a new type of welding equipment, due to the excellent welding effect, a wide range of applications, once the introduction of the processing industry to gain favor. However, due to the countless manufacturers of Fiber laser welding machines on the market, as the first time...Read more -

Frequently asked questions about laser engraving of different materials

CO2 laser engraving machine is no stranger to many friends, whether it is the crafts industry, advertising industry or DIY enthusiasts, will often use CO2 laser engraving machine for production. Due to the different materials, CO2 laser engraving parameters and the use of different methods, in th...Read more -

Laser welding makes aluminum alloy welding more efficient

Aluminum and aluminum alloys rank first in the world production of non-ferrous metals, and in recent decades, they have occupied a pivotal position in various materials used in modern engineering technology. Aluminum alloys are mainly used in aerospace, automotive, marine and even home decoration...Read more -

Laser welding will become the new focus of the laser industry

With the diversified development of new industries, processing technology is also changing, and the continuous research and development of laser technology makes the application field of laser technology more extensive. Laser welding machine as a high quality, high precision, low deformation, hig...Read more -

Brief description of laser welding for different materials in the electronics industry

With the popularity of smartphones, flat-panel TVs and other devices, the consumer electronics market has seen unprecedented growth. The ever-increasing competition has led the electronics manufacturing industry to place higher demands on product processes. Traditional processing methods have bec...Read more -

Introduction to the characteristics of the CO2 laser source

I believe that many friends for carbon dioxide laser cutting engraving machine is not unfamiliar, our life is common non-metallic crafts, advertising signs, etc. are made from it, but many people do not distinguish between carbon dioxide laser and fiber laser source are different. In fact, in ter...Read more -

Introduction to the advantages of fully enclosed laser engraving and cutting machine

With the continuous progress of society, people’s quality of products is also improving, the traditional manual and mechanical processing by equipment and technology constraints, it is difficult to cope with the complexity of today’s laser cutting and engraving process, not only affec...Read more -

Advantages of CO2 laser cutting machine for cutting acrylic material

Many friends are not unfamiliar with the mention of acrylic, everywhere on the street, such as the application of billboards have its silhouette, as acrylic crafts are becoming more and more popular, many processing plants are also more and more, in the face of expanding demand, specifically for ...Read more -

Precautions for bright surface cutting by fiber laser cutting machine

Fiber laser cutting machine is widely used in industrial production, sometimes we will find that some metal cutting surface is very smooth, such as a mirror, in fact, in the laser cutting process technology, the cutting surface of carbon steel can be cut very smooth, like a mirror-like effect, co...Read more -

Advantages and disadvantages of handheld laser welding machines versus desktop laser welding machines

Laser welding is a kind of welding method using laser technology, which mainly adopts non-contact welding and does not require pressure during the welding process, and has the advantages of fast welding speed, high efficacy, and small deformation. It is particularly flexible for welding shaped ma...Read more -

Cleaning and maintenance of the fibre laser cutting laser head

The high-precision laser processing method of fibre laser cutting machines far exceeds traditional processing methods in terms of efficiency and stability, creating huge production value for companies. As the core component of a fibre laser cutting machine, the cutting head is a laser output devi...Read more -

Fiber laser cutting machine daily maintenance precautions

Daily maintenance and precautions for fiber laser cutting machines such as high-powered heavy equipment is too important, because a fiber laser cutting machine less than tens of thousands of dollars more than hundreds of thousands of dollars, its performance has a direct impact on business produc...Read more -

Fiber laser cutting machine processing advantages

Sheet metal is used in many industries due to its light weight, high strength, electrical conductivity (ability to be used for electromagnetic shielding), low cost and good mass production performance. Laser processing technology is a non-contact cutting process, the energy and speed of the high-...Read more