-

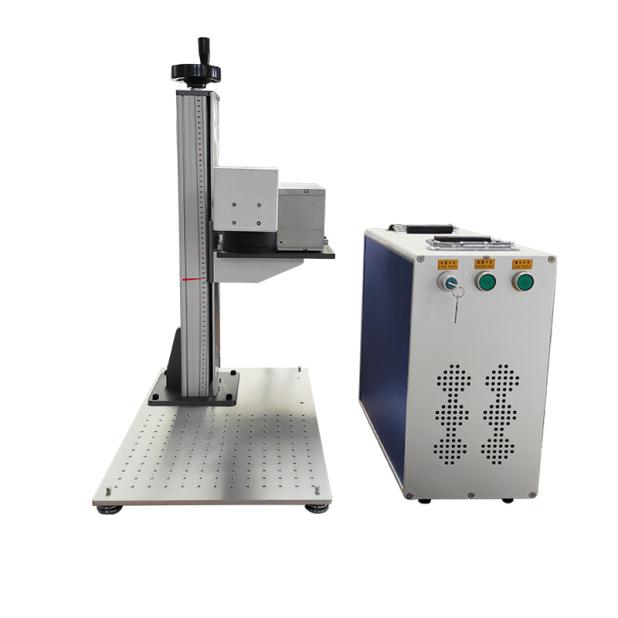

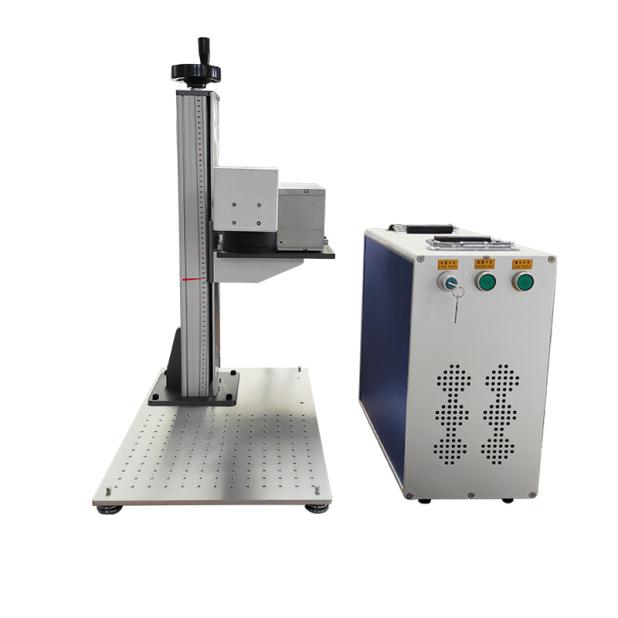

What is Mopa Laser Marking Machine?

MOPA laser marking machine is a marking equipment using MOPA (adjustable pulse width) fiber laser. It has good pulse shape control ability. Compared with Q-switched fiber laser, the pulse frequency and pulse width of MOPA fiber laser are independently controllable Yes, t...Read more -

What is UV laser marking machine?

The UV laser marking machine is applicable to a wide range of materials and can cover almost all of them, and the marking effect is better, the practicability is higher, and the operating cost is low. Advantages of UV laser marking machine: 1. Ultraviolet laser not only has good b...Read more -

What is Laser Pipe Cutting Machine?

Laser pipe cutting machine is mainly used to cut various metal hollow round pipe materials, such as stainless steel pipe, carbon steel pipe, galvanized pipe and other industrial and civil metal pipes. This kind of pipe is generally used in building materials, industrial pipelines, office furnitur...Read more -

What is Pulse Laser Cleaning Machine?

Pulse laser cleaning technology uses high-frequency high-energy laser pulses to irradiate the surface of the workpiece, and the coating layer can instantly absorb the focused laser energy, causing the oil stains, rust spots or coatings on the surface to evaporate or peel off instantly, and effect...Read more -

What is 3D Laser Marking Machine?

The appearance of laser marking machine is a major leap in the field of laser marking. It is no longer limited to the surface shape of the processing object on the class plane, but can be extended to the three-dimensional surface, so as to complete the efficient laser gr...Read more -

What is the 3 in 1 laser welding cutting and cleaning machine?

The 3 in 1 laser welding cutting and cleaning machine can weld, cut and clean metal materials. It can weld a variety of metal plates and pipes. It is mainly used to weld stainless steel, gold, silver, copper, galvanized sheets, aluminum sheets, various alloy sheets, and ...Read more -

Do you know the application field of CO2 laser cutting machine

With the continuous breakthrough of modern laser technology, the gradual popularization of laser technology, and the upgrading and development of related industries, the application space of laser technology continues to grow. At present, not only high-tech industries and precision processing ind...Read more -

What is jewelry laser welding machine?

Product description: It is mainly used for filling holes, spot welding trachoma and repairing welding of gold and silver jewelry. It is suitable for gold, silver, platinum, stainless steel, titanium and other multiple metals and their alloy materials. It can also be use...Read more -

What is Pulse Laser Cleaning Machine?

Pulse laser cleaning machine technology uses nanosecond or picosecond pulse laser to irradiate the surface of the workpiece to be cleaned, so that the surface of the workpiece absorbs the focused laser energy in an instant and forms a rapidly expanding plasma (highly ion...Read more -

Portable handheld fiber laser cleaning machine makes work more convenient

Traditional cleaning machine is bulky, it’s difficult to move to another place to work once the position is set. The new style of portable handheld fiber laser cleaning machine, with light size, easy operation, high power cleaning, non-contact, non-polluting features, for cast iron, carbon steel ...Read more -

What is 3 in 1 laser welding cutting and cleaning machine?

The 3 in 1 laser welding and cleaning machine can cut, weld and clean metals, without the need to purchase multiple laser equipment separately. It is suitable for welding stainless steel and aluminum alloys, and can also weld carbon steel, titanium alloys, etc., and can ...Read more -

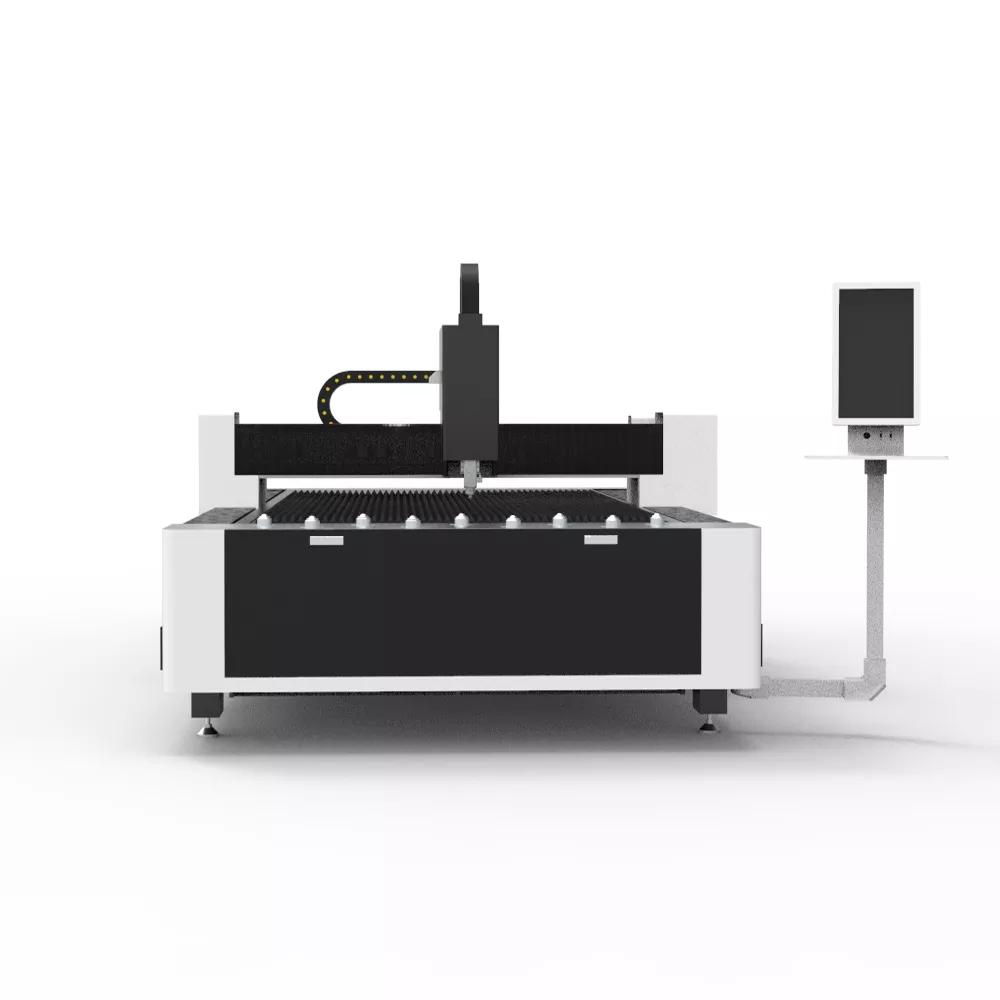

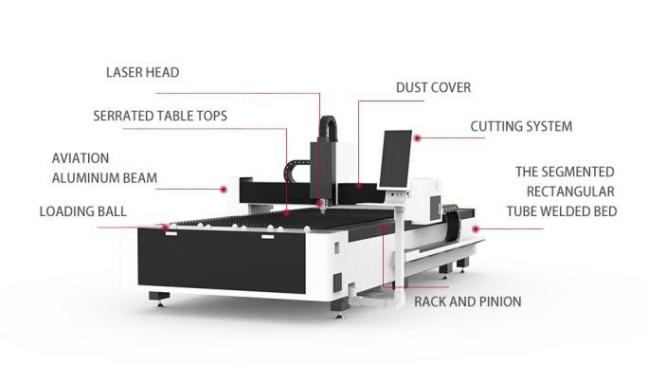

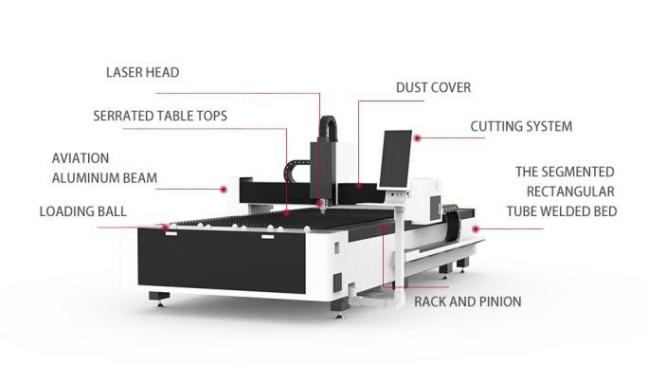

Do you know laser cutting machine?

Fiber laser cutting machine can do plane cutting, also can do bevel cutting processing, and the edge neat, smooth, suitable for metal plate and other high-precision cutting processing, coupled with the mechanical arm can be three-dimensional cutting instead of the origin...Read more -

What are the advantages of laser cleaning machine for rust removal?

1. The rust removal of laser cleaning machine is non-contact. It can be transmitted through optical fiber and laser cleaning gun to realize long-distance operation. It can clean parts that are difficult to reach by traditional methods. It is suitable for cleaning ships, ...Read more -

What is jewelry laser welding machine?

Jewelry laser welding machines are widely used in aviation, aerospace, sporting goods, jewelry, golf heads, medical equipment, aluminum alloy dentures, instruments, electronics, machining, automobiles and other industries, especially for filling holes in gold and silver ...Read more -

What is UV laser marking machine?

The UV laser marking machine is a series of laser marking machines, so the principle is similar to that of the laser marking machine, which uses laser beams to mark permanent marks on the surface of various materials. The effect of marking is to directly break the molecular chain of the substance...Read more -

Laser cleaning machine cleaning advantages

At present, the cleaning methods widely used in the cleaning industry include mechanical cleaning method, chemical cleaning method and ultrasonic cleaning method, but under the constraints of environmental protection and the requirements of high precision market, its application is greatly limite...Read more