-

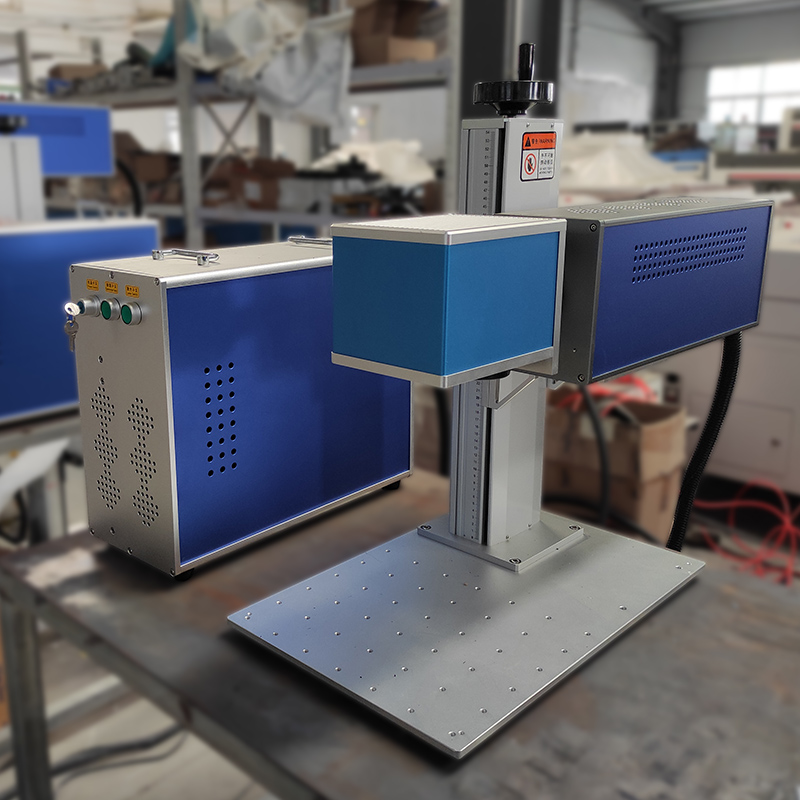

Do You Really Konw Laser Marking Machine?

The laser marking machine uses carbon dioxide gas to charge the discharge tube as a medium for generating laser light. When a high voltage is applied to the electrode, a glow discharge is generated in the discharge tube, which can make the gas molecules release laser light, and after amplifying t...Read more -

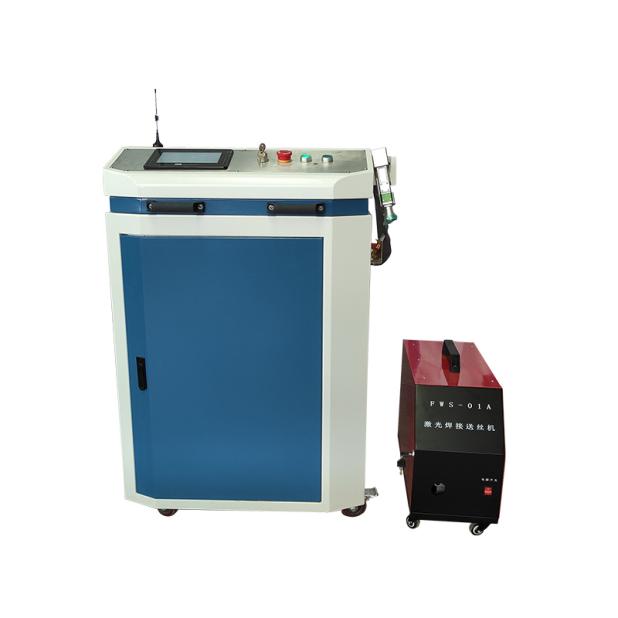

Why choose a laser welding machine?

With the technological development of laser intelligent equipment, in addition to laser cutting, laser welding equipment has also emerged, bringing about innovations in traditional welding processes. Laser welding belongs to non-contact welding, and the operation process...Read more -

Why do you choose Co2 laser engraving and cutting machine?

The principle of laser engraving is that the laser beam is transmitted and focused on the surface of the material by the optical mechanism, and the material at the action point of the high-energy density laser beam is rapidly vaporized to form pits. Use the computer to c...Read more -

Advantages of laser cleaning machine compared to traditional cleaning machine

Some traditional industrial cleaning machines will cause damage to objects in the process of cleaning objects, some have certain limitations, and some have serious environmental pollution. So what are the advantages of laser cleaning machines over traditional cleaning me...Read more -

Are you still using traditional cleaning techniques?

The laser cleaning machine effectively removes the attachment or surface coating on the surface of the cleaning object at high speed, so as to achieve a clean process. It is a new technology based on the interaction effect between laser and matter. Different from traditi...Read more -

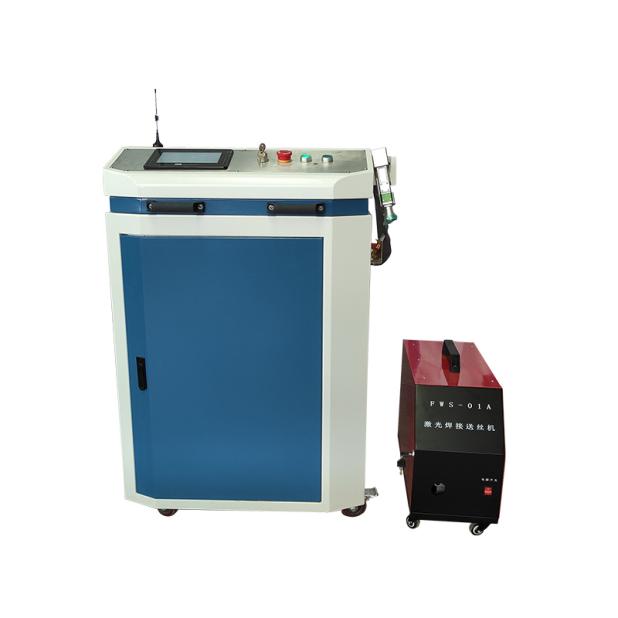

Why handheld laser welding machines are so popular?

Handheld laser welding machine replace the fixed optical path with a hand-held welding gun handheld welding flexible and convenient longer welding distance overcome the limitation of workbench space and can not be used when the workpiece size is not uniform and cannot be...Read more -

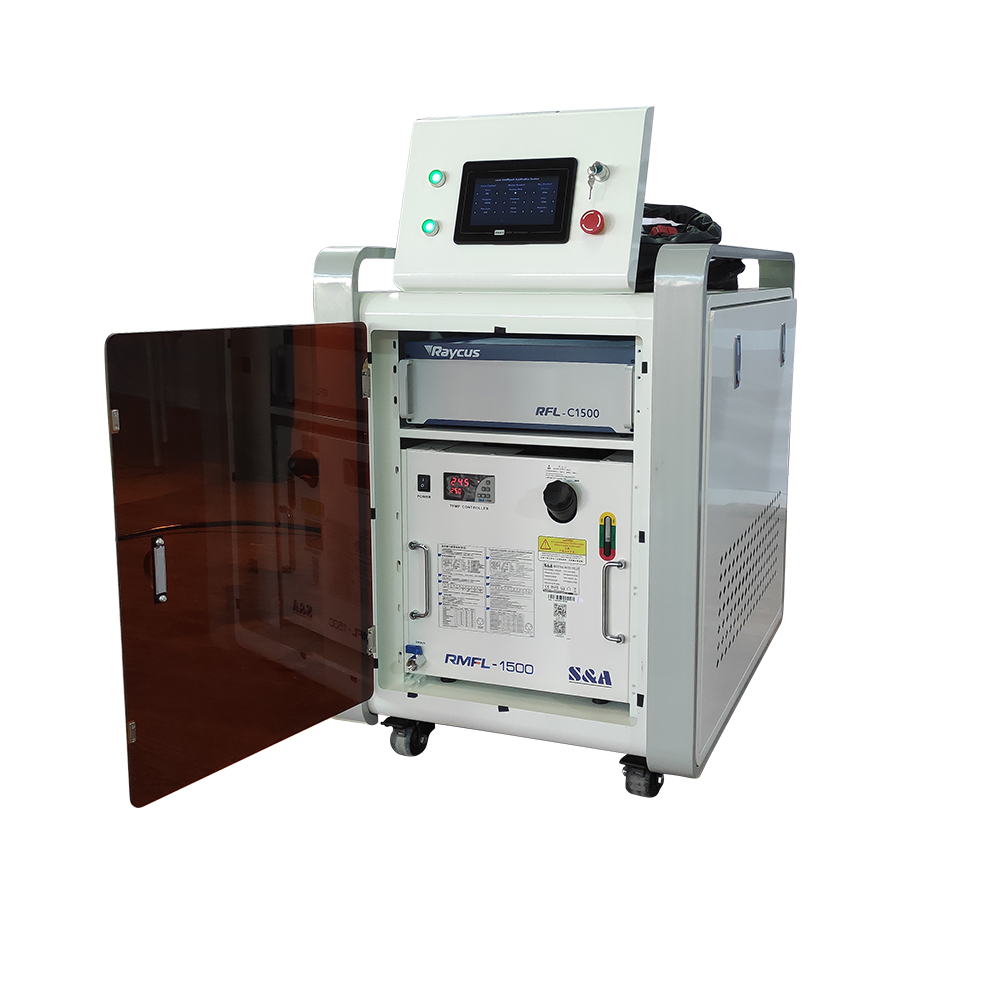

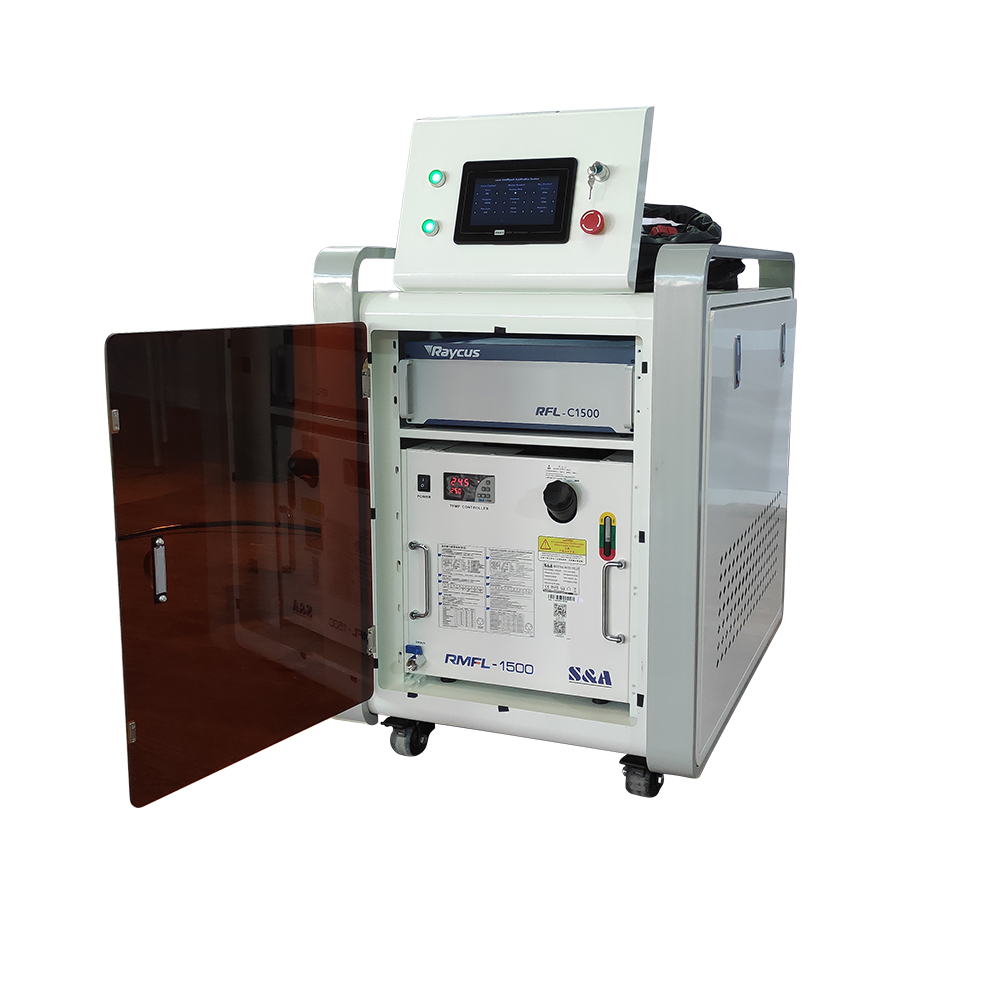

Why are laser welding machines so popular?

Laser welding machine is used in the field of welding, and it is one of the important aspects of the application of laser material processing technology. According to its working mode, it can be divided into laser mold welding machine, automatic laser welding machine, an...Read more -

What you don’t know about laser welding equipment

With the changes of the market and the continuous progress of the industrial field, the demand of modern consumers for products has been unable to meet the basic welding, and laser welding has emerged. Up to now, laser welding has become an indispensable key to the development of many industries....Read more -

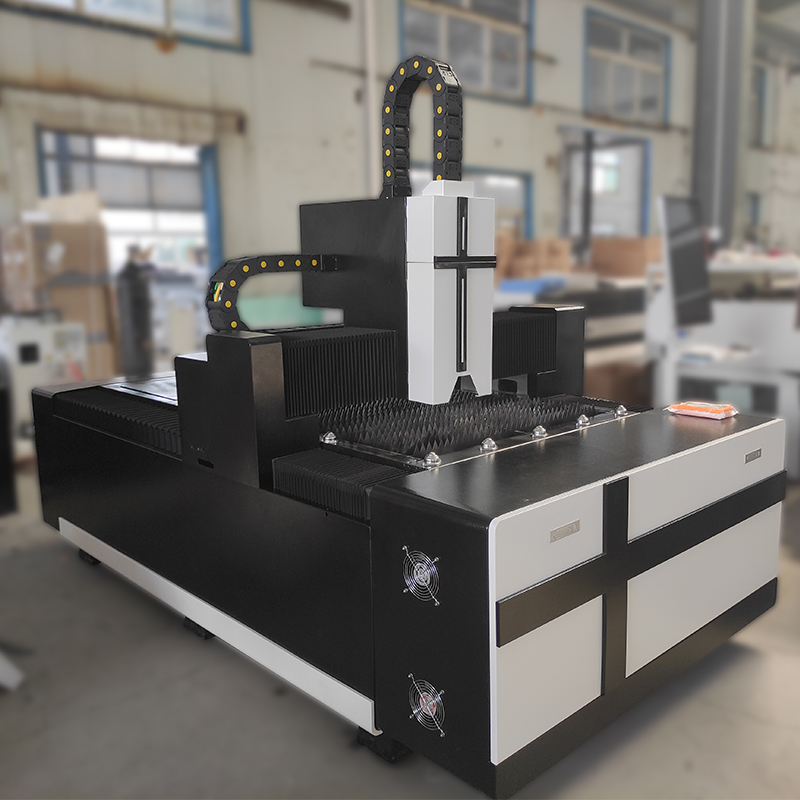

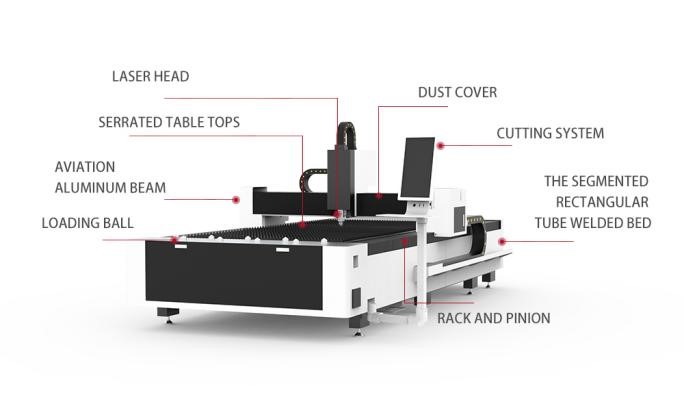

Amazing! Is this the laser cutting machine?

The so-called laser cutting is the energy released when the laser beam is irradiated on the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. Features such as smoothness and low processing cost will gradually im...Read more -

Do you know the application field of CO2 laser cutting machine

With the continuous breakthrough of modern laser technology, the gradual popularization of laser technology, and the upgrading and development of related industries, the application space of laser technology continues to grow. At present, not only high-tech industries and precision process...Read more -

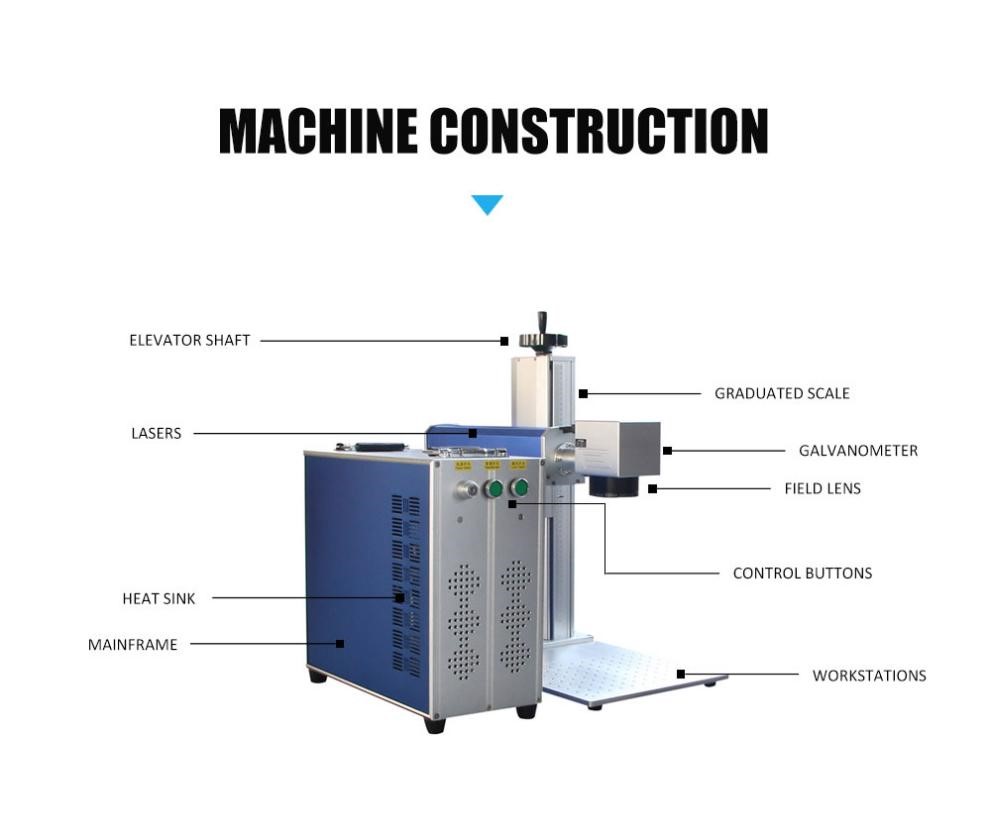

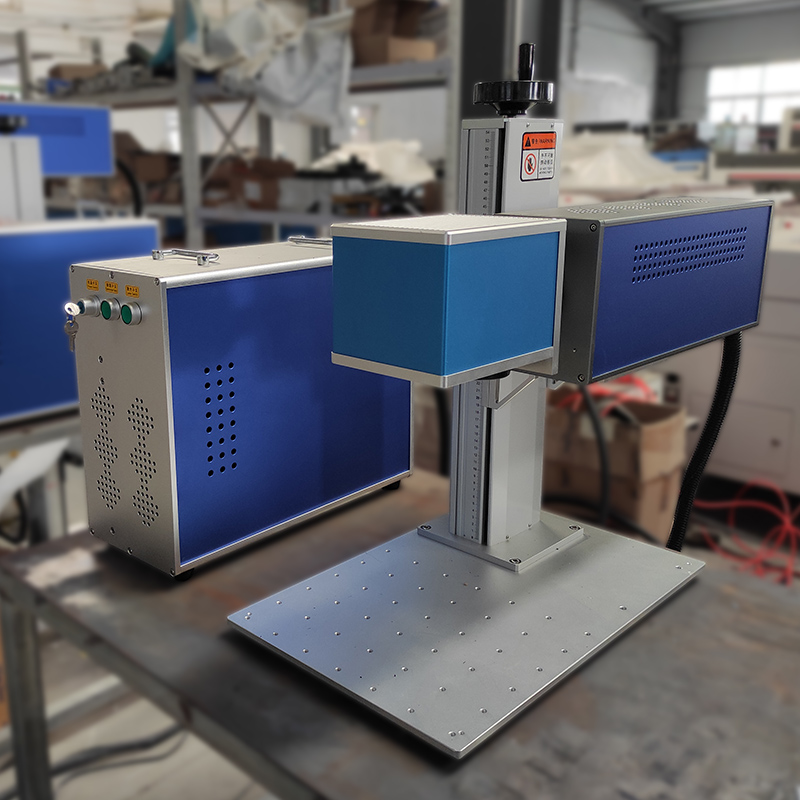

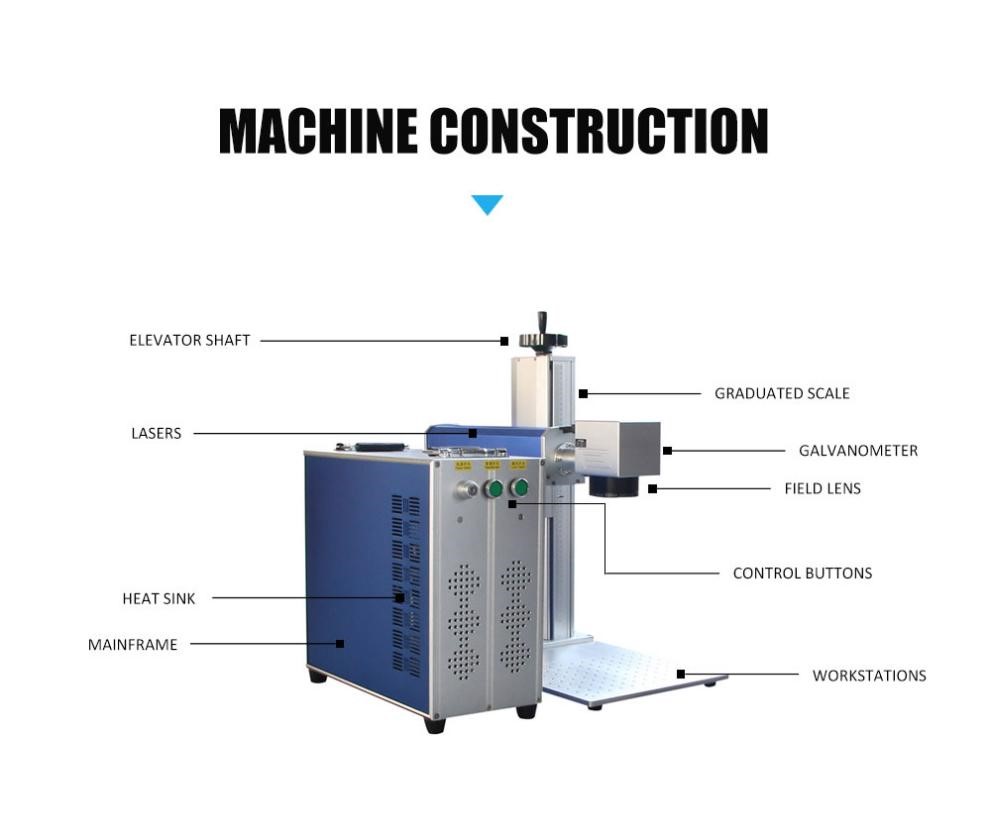

Take you to understand the optical fiber marking machine

In recent years, with the continuous development of modern industry, laser technology has gradually become popular, and the application of laser marking machine technology in various major industries has become more and more extensive. More and more manufacturers continue to introduce various las...Read more -

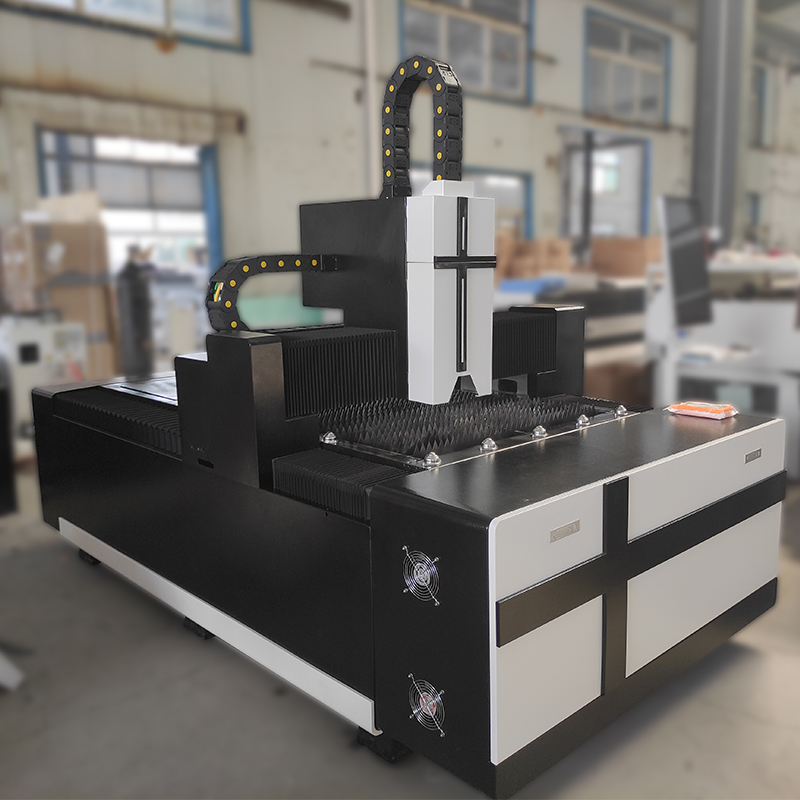

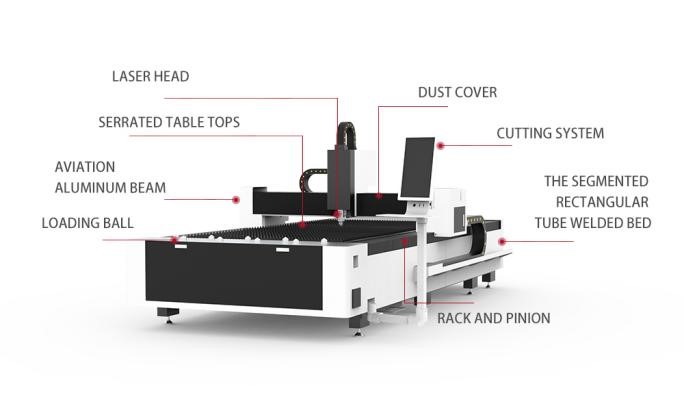

Do you really know fiber laser cutting machine?

In this era of rapid development, some new technologies have emerged. Laser cutting technology is a particularly important one. As one of the core devices of high-end manufacturing equipment, fiber laser cutting machine is favored in the market because of its advantages. There are various kinds o...Read more -

Are you still using traditional cleaning techniques?

The traditional industrial cleaning machine will cause some damage in the process of cleaning objects. And some of them have many limitations and serious environmental pollution. In order to solve these difficult problems, laser cleaning machine was born! So what are the...Read more -

Let me show you how to choose laser welding equipment correctly

Laser welding is one of the important aspects of the application of laser material processing technology. With the continuous maturity of laser welding technology, it also drives the continuous development of laser welding equipment. At first, the technology of laser equipment in China was not ma...Read more -

Do you really know the truth about fiber laser cutting machines?

Fiber laser machine is a new type of machine that is newly developed in the world. It outputs high energy density laser beam and concentrates on the surface of the workpiece, so that the area irradiated by ultra-fine focal spot on the workpiece can be instantly melted and vaporized, and automatic...Read more -

Take you into the price misunderstanding of fiber cutting machine

With the continuous development of the industry, laser cutting technology has penetrated into various industries, and due to the urgent increase in demand for laser cutting equipment in my country, domestic laser cutting equipment manufacturers have become more competitive in the market in order ...Read more