Metal steel aluminum alloy round tube stainless steel automatic spot welding laser welding machine

With this motto in mind, we’ve come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for One of Hottest for China Low Price 1000W 1500W Max Raycus Fiber Source Handheld Laser Welding Machine, Never-ending improvement and striving for 0% deficiency are our two main high-quality policies. Should you need anything, really don’t hesitate to make contact with us.

With this motto in mind, we’ve come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Laser Welding Machine, Mould Laser Welding Machine, With a state-of-the-art extensive marketing feedback system and 300 skilled workers’ hard work, our company has developed all kinds of goods ranging from high class, medium class to low class. This whole selection of fine solutions offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also present good OEM services to many famous brands.

|

NO. |

Name |

Parameter |

|

1 |

Machine model |

Hand-held fiber laser welding machine |

|

2 |

Laser source |

Raycus |

|

3 |

laser power |

1000W、1500W、 |

|

4 |

laser wave length |

1070 NM |

|

5 |

Uptime |

24 hours |

|

6 |

operate mode |

continuation/ modulate |

|

7 |

Welding speed range |

0~120 mm/s |

|

8 |

Laser pulse width |

0.1-20ms |

|

9 |

Cooling chiller |

Industrial water chiller |

|

10 |

Working environment temperature range |

15~35 ℃ |

|

11 |

Humidity range of working environment |

< 70% No condensation |

|

12 |

Welding thickness recommendations |

0.5-3mm |

|

13 |

Welding gap requirements |

≤0.5mm |

|

14 |

working voltage |

220 V |

|

15 |

Dimensions |

1140*670*1400 mm |

|

16 |

Weight |

270kg |

Product Advantages

1. Handheld welding head is flexible and convenient, which can realize outdoor welding.

2. High welding efficiency, 2 to 10 times faster than conventional welding.

3. The operation mode of the handheld torch enables the workpiece to be welded at any angle in any part.

4. It is suitable for spot welding of various complex welded joints and various equipment.

5. Compared with traditional welding, the weld seam is flat and beautiful, with very few defects, deeper welding depth and smaller thermal stress deformation.

6. can be precisely controlled, with a small focused light point, which can be positioned with high precision and easily automated.

7. can realize the welding between some kind of dissimilar materials.

8. can realize spot welding, butt welding, stack seal welding, etc.

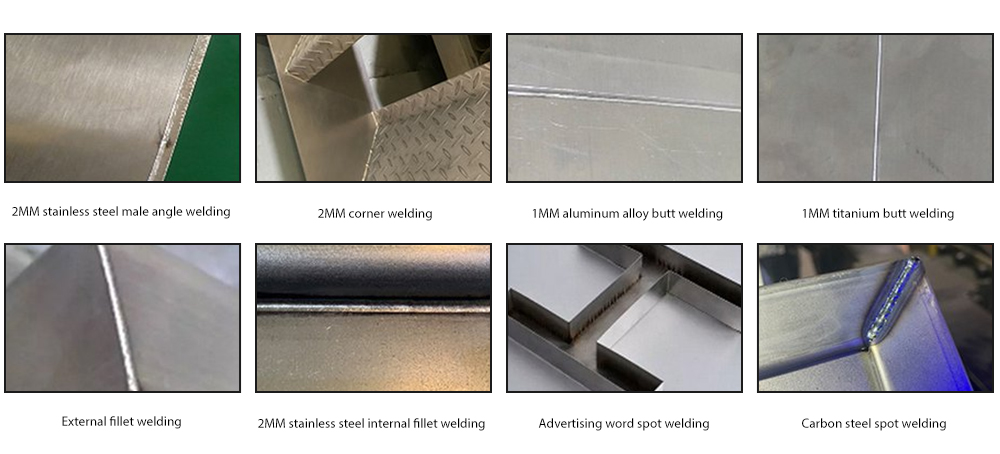

Weldable method

Sample Show

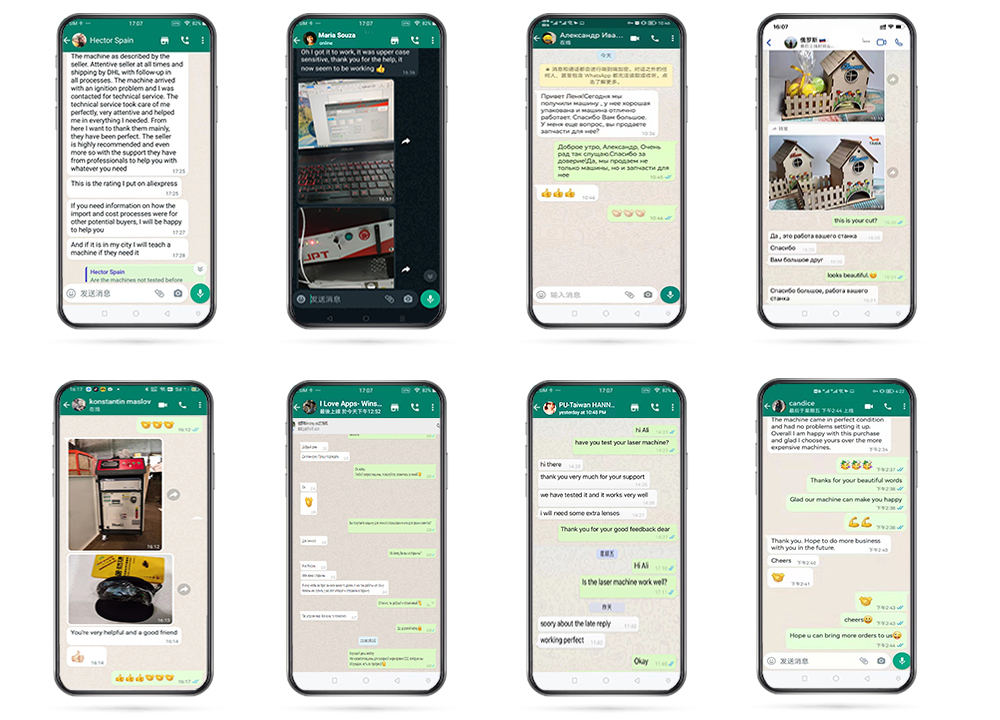

AFTER-SALE SERVICE

1.We have a professional and experienced after-sales team. We support door-to-door after-sales service. In order to effectivelysolve customer problems and help customers use the machine better, we will conduct skill assessments on our after-sales team every year.

2. We support e-mail, telephone, Wechat, Whatsapp, video and so on. As long as we can help you, you can choose the most convenient way you think

3. We support 2 years warranty,when you have any questions, you cancontact us anytime.