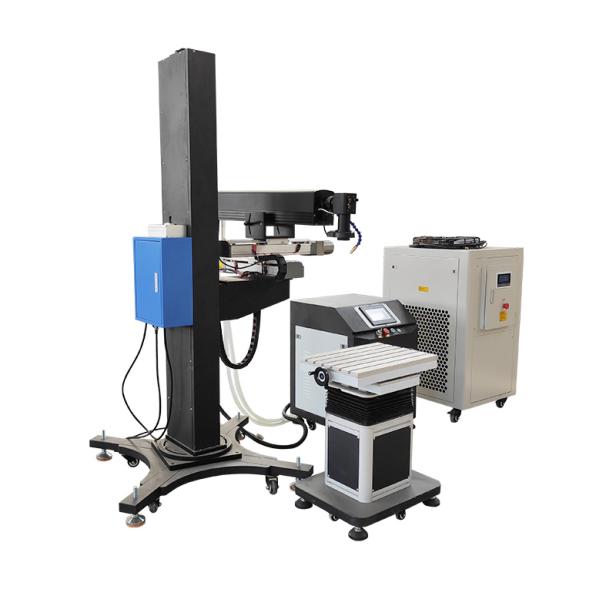

Laser weld muchinaInoshandiswa mumunda weWelding, uye ndechimwe chezvinhu zvakakosha pakushandisa kweLaser zvinhu kugadzirisa tekinoroji. Zvinoenderana nemhando yayo yekushanda, inogona kukamurwa kuita Laser Mold Welding Machine, uye Laser Bota Weling Machine, etc. Ndezvipi zvakanakira zveLaser Welding Machine?

- Ø Zvakanakira

1. Mushure mekutarisa Laser, density density yakakwira. Mushure meiyo yakakwirira-simba semagetsi-yakarongeka mode laser yakatarisana, iyo focal Spot Diameter idiki kwazvo.

2. Iyo laser westing yekumhanya nekukurumidza, kudzika kwakakura, uye kusvibisa kuri diki. Nekuda kwesimba repamusoro density, maburi madiki anoumbwa mune izvo zvesimbi mukati mevanaLaser Welding maitiro, uye iyo laser simba inoendeswa kune yakadzika chikamu chebasa rekushanda kuburikidza nemakomba madiki, uye pane kushoma pasi dialsionus. Iko kumhanya kuri kukurumidza, uye nzvimbo yeWolketi pane yuniti nguva yakakura.

3 Izvo zvakanyatsokosha kwazvo kuti ubatwe nekunyatsojeka uye nekupisa-zvinongedzo zvikamu, izvo zvinogona kudzivisa post-weld orthopedic uye sekondari kugadzirisa.

4

5. Inogona teld Refractory zvinhu, senge Titanium, etcz, etc., uye inogona michero yezvisikwa zvakasiyana, senge tantalum uye mitezo miviri ine zvivakwa zvakasiyana-siyana zvakasikwa pamwe, uye mhedzisiro yacho yakanaka.

6. Micro-Welding inogona kuitwa. Mushure mekunge Laser Beam yakatarisana, nzvimbo diki inogona kuwanikwa, uye inogona kuve yakagadziriswa, iyo inogona kuiswa kugungano yeComputer yeMicro uye zvidiki zvikamu muhuwandu hwekugadzira otomatiki. Kwete chete kugona kwekugadzirwa kwakavandudzika zvikuru, asiwo nzvimbo yekushisa-yakakanganisa idiki uye mutengesi akabatanidzwa akasvibiswa, ayo anovandudza zvikuru kunaka

7. Inogona kunge yakaomeswa-kusvika-kusvika zvikamu uye kushandisa zvisiri-zvekutaurirana-kureba-kureba, iyo ine shanduko huru.

8. Kazhinji, hapana simbi yefirita inowedzerwa. Kana yakadzivirirwa zvizere neinerersi gasi, iyo weld yakasununguka kubva kuAutmpheric kusvibiswa

9. Iyo tysteming system inochinjika uye iri nyore kune otomatiki.

10.Laser weld muchinaLaser Welding zvakafanana neElectron Beam ichichengeta mune zvakawanda zveElektron Beam Welding, asi maEkiresi anogona kungoiswa muAcuum, saka tekishinari anogona chete kuCustom, uye Laser Welding Tekinoroji inogona kushandiswa mune yakakura mhando yenzvimbo dzebasa.

JINANA Goridhe Mark Cnc Machiny Co, Ltd.inhambwe yeTech-Tech Interprise yakasarudzika mukutsvaga, kugadzira michina seinotevera: laser denraver, fiber laser mencar muchina, cnc router. Zvigadzirwa zvakazoshandiswa zvakanyanya mumabhodhi ekushambadzira, mhizha uye kuumbwa, chisimbiso, chimbuya, chinongedzo uye kushongedza matombo, maindana emabwe, maindasitiri emakonzo, uye zvikaitika. Pazasi pekutora tekinoroji yepamberi, isu tinopa vatengi zvakanyanya kugadzirwa kwakanyanya uye vakakwana mushure mekutengesa mushure-basa. Mumakore achangopfuura, zvigadzirwa zvedu zvakatengeswa kwete kuChina chete, asi zvakare kusvika kuSoutheast Asia, Middle East, Europe, South America nemamwe misika yemakungwa.

Email: cathy@goldmarklaser.com

Wecha / WhatsApp: +8615589979166

Kutumira Nguva: Aug-02-2022