Sharaxaada Alaabta

Mashiinka goynta Plasma oo leh darawal laba geesood ah, hawlgal xasiloon, qaabeyn wanaagsan iyo hufnaan sare, waxaa loo isticmaali karaa xariijimo waaweyn, dhexdhexaad ah iyo yar yar oo bir ah oo ka hooseeya birta kaarboon ee kala duwan, birta manganese iyo walxo kale oo bir ah.Waxaa lagu hagaajin karaa toosh sawireed badan iyadoo loo eegayo shuruudaha adeegsadaha, waxaana sidoo kale lagu habeyn karaa nidaamka toosan ee qaabaysan ee CNC iyadoo loo eegayo baahida, oo leh nidaam toos ah oo toos ah oo toos ah ololka awoodda.

Tilmaamaha alaabta

Horumarinta mashiinka goynta Plasma ilaa hadda, gaaska shaqada ayaa loo isticmaali karaa (gaaska shaqada waa dhexdhexaadiyaha plasma arc, laakiin sidoo kale jirka kulaylka qaada, laakiin sidoo kale in laga saaro birta dhalaalaysa ee la jeexay) sifooyinka goynta ee balaasmaha arc iyo tayada goynta, xawaaraha ayaa saameyn weyn ku leh.Gaasaska shaqada ee sida caadiga ah loo isticmaalo waa argon, hydrogen, nitrogen, oxygen, hawo, uumiga biyaha iyo gaaska isku dhafka ah qaarkood.

Mashiinnada goynta Plasma waxaa si weyn loogu isticmaalaa warshadaha kala duwan sida baabuurta, gawaarida, weelasha cadaadiska, mashiinada kiimikada, warshadaha nukliyeerka, mashiinada guud, mishiinnada injineernimada iyo qaababka birta!Habka badbaadada, fudud, waxtarka leh, isku dhafan iyo deegaanka saaxiibtinimo ee habka kulaylka (goynta, alxanka, birta, deminta, buufinta, iwm.) ee biraha ka soo dhumucda 0.3 mm dhumucda 0.3 mm iyadoo laga helayo balaasmaha uumiga biyaha waa kii ugu horreeyay ee noociisa ah taariikhda. ee warshadaha biraha.

Mabda'a hawlgalka

Plasma waa gaas kuleyliya heerkul aad u sarreeya aadna u leh ionised, waxay ku wareejisaa awoodda arc-ga qalabka shaqada, kulaylka sarreeya wuxuu keenaa in qaybta shaqada ay dhalaasho oo la afuufo, sameynta xaalad shaqo oo ah jarista balaasmaha.Hawo cadaadisku waxay gashaa shuclada waxaana loo qaybiyaa qolka gaaska laba siyaabood, sida inay sameeyaan gaaska balaasmaha iyo gaasta caawinta.Arka balaasmaha ayaa u adeegta si ay u dhalaaliso birta, halka gaaska kaaliyaha ah uu qaboojiyo qaybaha shumaca oo uu ka damiyo birta dhalaalisay.Korontada goynta waxay ka kooban tahay laba qaybood: wareegga ugu weyn iyo wareegga xakamaynta.Mabda'a korantada: wareegga ugu weyn wuxuu ka kooban yahay xiriiriye, koronto awood saddex-waji ah oo leh caabbinta qulqulka sare, hagaajinta buundada saddex-waji, gariirad hagitaan-sare oo joogto ah iyo qaybaha ilaalinta.Iska caabbinta qulqulka sare waxay u horseedaa sifo sare oo dibadda ah oo sahayda korontada ah.Wareegga xakamaynta waxaa lagu dhammeeyaa batoonka riix-badhanka ee shuclada dhammaan habka goynta: ka-hortagga-hawo-qaadista - korontada wareegga ugu weyn - bilowga sare ee arc - habka goynta - arc nasashada - joogsiga.Awoodda korontada ee wareegga ugu weyn waxaa xakameynaya xiriiriyaha;socodka gaaska waxaa lagu xakameynayaa waalka solenoid;wareegga xakamaynta ayaa koontaroolaya oscillator-ka sarreeya ee soo noqnoqda si uu u shido arc oo uu joojiyo inta jeer ee sarreeya ka dib markii la aasaasay arc.

Xuduudaha alaabta

| Qaabka | Mashiinka goynta 1530 63Alasma (qaabaynta sare) |

| X,Y goobta shaqada | 1500*3000mm |

| Goobta shaqada | 150mm |

| Cabbirka baakadka | 2280mm*3850mm*1850mm |

| sariirta laamiga | Qaab dhismeedka birta oo aad u qaro weyn |

| Awoodda mashiinka | 16kw |

| Danab shaqaynaysa | 380V saddex waji 60hz |

| Dib u dhig saxnaanta | 0.02mm |

| Habka saxda ah | 0.1mm |

| Xawaaraha goynta ugu badan | 12000mm/daqiiqo |

| Habka xakamaynta Dhererka Tooshka | Toos ah |

| Dhumucda goynta | Ugu badnaan 12mm birta kaarboon |

| Korontada Plasma | LGK63A |

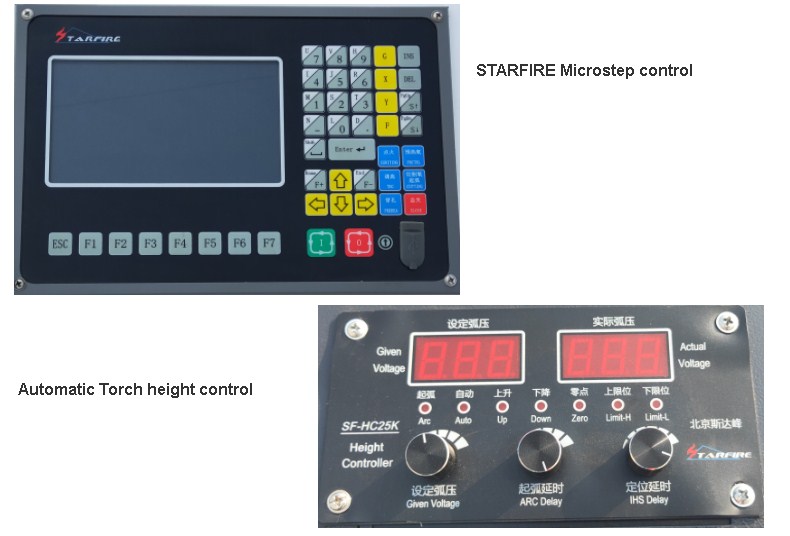

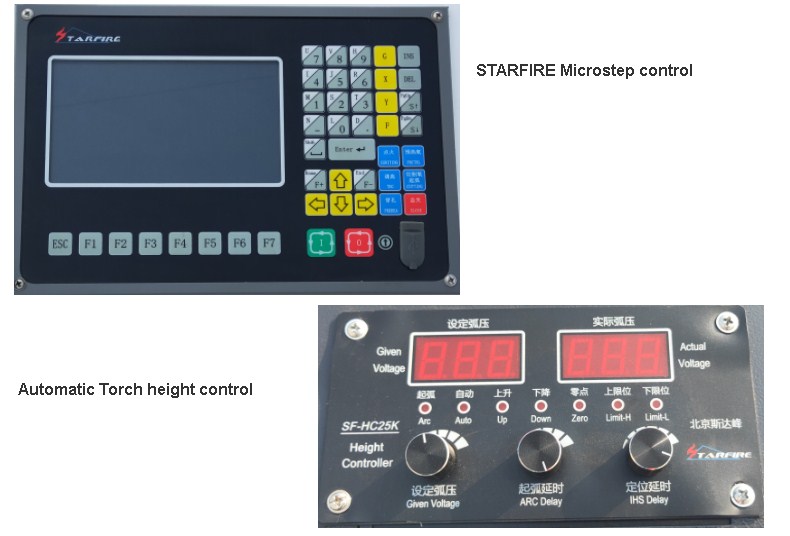

| Nidaamka xakamaynta | STARfire |

| Matoorada | Matoorka Stepper |

| Software | Starcam |

| Miisaanka | 1600KG |

| Cadaadiska Hawada Plasma | Ugu badnaan.0.8Mpa |

| Heerkulka shaqada | -10°C-60°C.Qoyaanka qoyaanka, 0-95%. |

| Cabirka Muujinta LCD | 7 inji |

Faahfaahinta alaabta

Qalabka lagu dabaqi karo

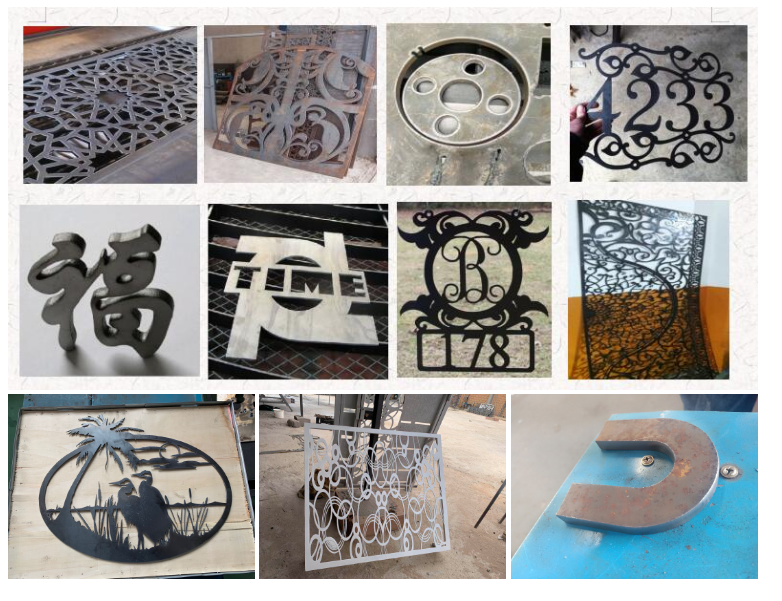

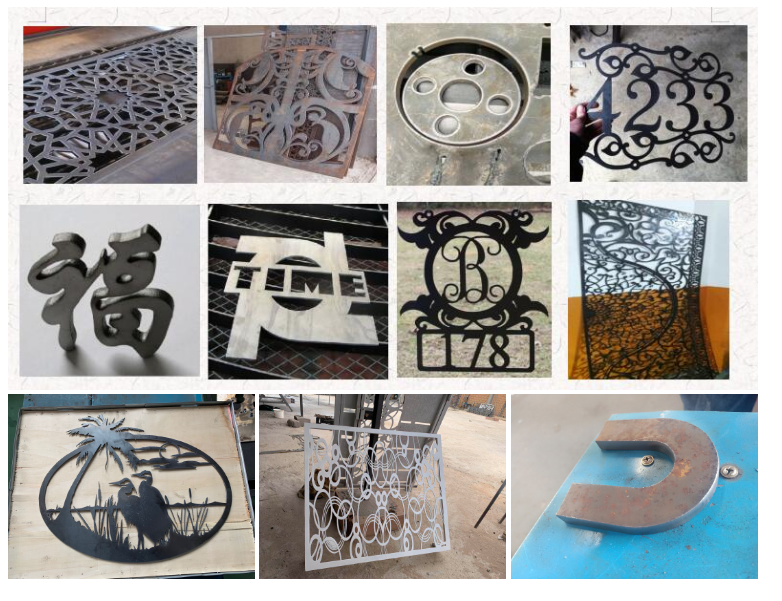

To mashiinka goynta balaasmaha1530, waxay gooysay dhammaan biraha, oo ay ku jiraan laakiin aan ku xaddidnayn xaashida aluminium, xaashida birta, galvanized (birta) xaashida, birta khafiifka ah, xaashida titanium, birta, birta iwm.

Warshadaha lagu dabaqi karo

Warshadaha xayeysiinta: Calaamadaha xayeysiinta, calaamadaynta astaanta, alaabada qurxinta, wax soo saarka xayeysiinta iyo agabyada kala duwan ee birta ah.

Wershada Caaryada: Xardho xardho bir ah oo ka samaysan naxaas, aluminium, birta iyo wixii la mid ah.

Warshadaha birta ah: Birta, Birta Kaarboonka, Biraha, birta alloy, birta guga, saxan naxaas ah, saxan aluminium, dahab, qalin, Titanium iyo saxan bir kale iyo tuubo.

Sawirada mashiinka

Sawirrada warshadda iyo dhoofinta