Iyadoo horumarinta joogtada ah ee mashiinka goynta laser fiber, codsiga mashiinka goynta laser fiber kaliya kuma koobna beerta warshadaha, warshado badan iyo in ka badan ayaa sidoo kale bilaabay in si ballaaran loo isticmaalo, kaas oo door weyn ka ciyaaray kor u qaadida horumarinta ee warshadaha laysarka. . Soo-saarayaal badan oo mashiinnada goynta laser-ka ah ayaa si joogto ah u raadinaya horumarro lagu horumarinayo heerarka awoodda ee horumarka, waxaana jira ifafaale tartan ah, taas oo abuurta khiyaali macaamiisha ah in illaa iyo inta heerka korantadu uu si gaar ah u sarreeyo, heerka tayada badeecadu waa gaar ahaan. sare Dhab ahaantii, fikraddaani waa khalad.

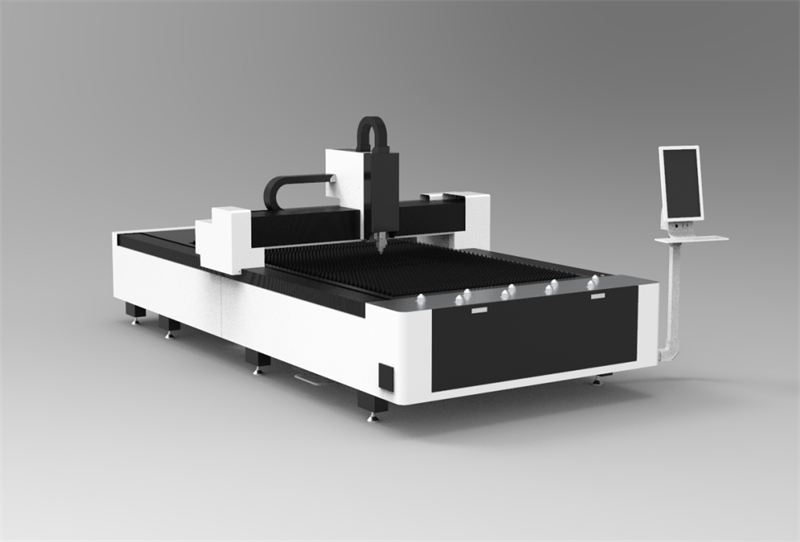

Maalmahan, baahiyaha isticmaalayaashu waxay go'aamiyaan horumarinta iyo wax soo saarka alaabta. Marka macaamiishu doortaan mashiinnada goynta laser fiber-ka, kaliya maaha inay qiimeeyaan shirkadu waxay samaysay mashiinka goynta laser awood sare, laakiin sidoo kale waxay qiimeeyaan waxa mashiinka goynta laser-kaagu soo saaro. Wax ku ool ah Si kale haddii loo dhigo, haddii adeegsaduhu uu gooyn karo qalab tayo sare leh oo leh mashiinka goynta 1000W fiber laser goynta, iyo saamaynta isticmaalka 2000W maaha mid u wanaagsan sida ay tahay, markaa mashiinka goynta laser fiber 2000W macno la'aan isticmaaluhu. Aynu raacno falanqaynta Jinyin Laser ka shanta dhinac ee soo socda, iyo saamaynta awoodaha kala duwan ee tayada goynta marka la iibsanayo mishiinka goynta laser fiber.

1. Awoodda wax soo saarka laser

Awoodda wax-soo-saarka ee mashiinka goynta laser-ka fiber-ka, ayaa sii kordheysa dhumucda walxaha la gooyn karo, iyo tayada goynta u dhiganta. Sidaa darteed, isticmaaluhu waa inuu ogaadaa dhumucda iyo nooca alaabta ee habka hore ee wax iibsiga si looga fogaado in aan awoodin in la gooyo ama tayada goynta la rabo lama heli karo. Intaa waxaa dheer, heerka sare ee heshiiska u dhexeeya qaabka goynta laysarka iyo walxaha, tayada goynta ayaa ka sii fiican. .

2. Focus of jarida laser

Tani waa dhibaato aad u caan ah, ama jumladaas, kaliya marka booska diiradda la saaro, waxaad gooyn kartaa alaab gaar ah oo tayo fiican leh.

3. Qalafsanaanta alaabta

Dhammaanteen waan ognahay in habka farsamaynta dabacsan ee goynta laser fiber uu wanaagsan yahay, oo aan xaddidnayn qaabka shaqada, laakiin waxay xaddidan tahay dusha sare oo aan la gaari karin saameynta goynta qumman. Mar alla markii dusha sare ee maaddada, ay ka sii fiicnaato tayada goynta. Sidaa darteed, xasiloonida qalabka mashiinka ayaa sidoo kale aad muhiim u ah. Waa lagama maarmaan in la hubiyo jawiga shaqada ee goynta laysarka.

4. Xawaaraha jarista

Mashiinka goynta laser fiber 1000 watt, oo loogu talagalay qalabka birta kaarboon ee ka hooseeya 10mm, marka dhumucda birta kaarboon ay ka yar tahay 2mm, xawaaraha goynta wuxuu noqon karaa ilaa 8 mitir daqiiqadii. Marka dhumucda birta kaarboonku ay tahay 6mm, xawaaraha goyntu waa qiyaastii 1.6 mitir daqiiqadii. , Oo marka dhumucda birta kaarboonku tahay 10mm, xawaaraha goynta wuxuu ku saabsan yahay 0.6 mitir-0.7 mitir daqiiqadii.

2000 watt fiber laser goynta mashiinka, marka dhumucda birta kaarboon waa 1mm, xawaaraha goyntu si gaar ah ayuu u sarreeyaa ilaa 10 mitir daqiiqadii, marka dhumucda birta carbon waa 6mm, xawaaraha goyntu waa qiyaastii 2 mitir daqiiqadii, iyo marka dhumucda birta kaarboonku waa 10mm, Xawaaraha jarista wuxuu ku saabsan yahay 1 mitir daqiiqadii.

5. Dhumucda walxaha birta ah

Marka dhumucda walxaha birta kaarboon ay ka yar tahay 2mm, soo-saareyaasha ahmiyadda weyn u leh jarista xawaaraha waxay tixgelin karaan isticmaalka mishiinka goynta laser fiber 2000w, laakiin mashiinka 2000w wuxuu ku xidhan yahay inuu ka sarreeyo 1000w marka la eego qiimaha qalabka iyo kharashka hawlgalka . Marka qalabka birta kaarboon uu ka weyn yahay 2mm, mashiinka 2000w aad ugama dheera xawaaraha goynta 1000w. Sidaa darteed, isbarbardhigga dhammaystiran, mashiinka goynta laser fiber 1000w wuu ka kharash badan yahay mashiinka goynta laser fiber 2000w.

Waqtiga boostada: Mar-12-2021