Ho na le mekhoa e mengata ea ho cheselletsa tšepe, joalo ka argon arc ea setsotjheseletsa, ho tjheseletsa ka motlakase le metjhini e meng e tlwaelehileng ya ho tjheseletsa.

Lilemong tsa morao tjena, ho itšeha ka laser lelaser tjheseletsaba kene tšimong ea ho sebetsa le ho etsa tšepe. Mochini o ts'oaretsoeng ka letsoho oa laser o na le melemo e totobetseng ka katleho le boiketlo, 'me o hlahisitse ka potlako "metal welding iteration effect", e ka batlang e nkela sebaka sa argon arc welding, welding ea motlakase le mekhoa e meng. E ka sebelisoa monyako le lifensetere hardware, mesebetsi ea matsoho, mabone, tšepe papatso, hardware kichineng le kamore ea ho hlapela, tableware, lisebelisoa kichineng, temo le meru mechine, thepa ea bongaka, thepa ea lipapali fitness le industries tse ling.Metal laser cutting, koba le tjheseletsa kopantswe moralo oa ts'ebetso.

Melemo ea mechine ea ho tjheseletsa laser ka letsoho ke efe?

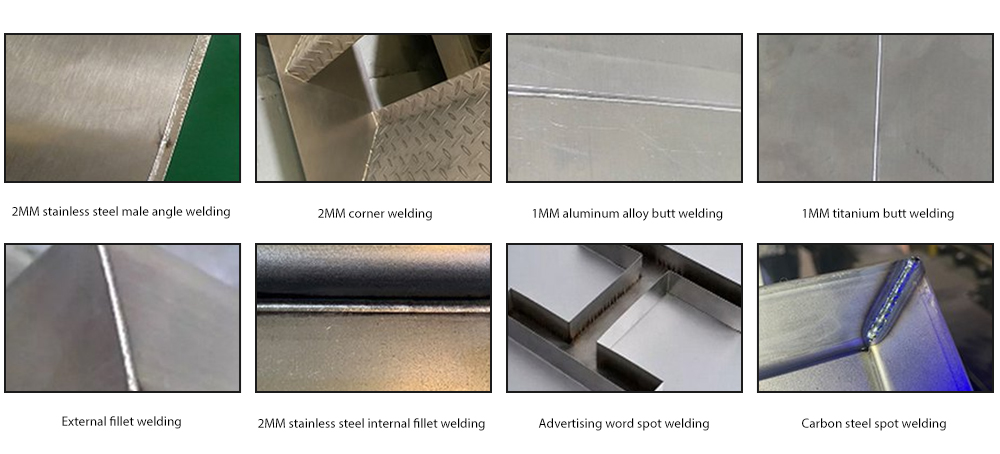

Mochini o ts'oaroang ka letsoho oa laser welding o ntlafatsa mefokolo ea welding joalo ka undercut, ho kenella ho sa phetheheng, porosity e teteaneng le mapetsong a ts'ebetso ea khale ea welding. The weld seam ka mor'a ho tjheseletsa e boreleli ebile e ntle, e fokotsang mokhoa o latelang oa ho belisa le ho boloka nako le litšenyehelo. 'Me ho na le lisebelisoa tse fokolang, bophelo bo bolelele,' me e ka ba bonolo ebile e loketse libaka tse fapaneng.

1. Beha li-parameter feela 'me u ka qala hang-hang. Kamora ho fetola nozzle, ha ho na taba hore na ke welding e bataletseng, angle e ka hare, angle ea kantle, welding ea overlap, joalo-joalo.

2. Lebala la laser ke karolelano, boleng bo phahameng, bo tsoelang pele ebile bo tsitsitse, 'me ho bonahatsa ke karolelano. Phello ea tjheseletsa e ts'oana ho sa tsotelehe hore na ke motho ea qalang kapa ea tloaelehileng, 'me ho ke ke ha e-ba le mathata a kang pores, weld bead, weld penetration, le workpiece deformation.

3. Bakeng sa lisebelisoa tsa tšepe tse kang tšepe e sa hloekang, lakane e entsoeng ka masenke, poleiti e batang, joalo-joalo, ha e le hantle e ka qeta nako e le 'ngoe ka potlako, e leng makhetlo a' maloa ka potlako ho feta mekhoa e meng ea ho cheselletsa.

Kenyelletso ea Handheld Laser Welding Machine

The handheld laser welder ke sesebelisoa sa boqapi se nkang sebaka sa tjheseletsa ea setso. E na le lebelo la ho tjheseletsa ka lebelo ho feta tjheseletsa ya setso.

1. E bonolo, e bonolo ho ithuta, e nahanela ebile e bonolo. Ho amohela sebopeho se kopantsoeng, mosebeletsi ha a hloke haholo, koetliso e bonolo e ka sebelisoa, ts'ebetso e bonolo, e potlakileng ho qala; multi-dimensional tjheseletsa, nahanela le bonolo;

2. Litsenyehelo tse tlase tsa matsete le litšenyehelo tsa tlhokomelo. Ho tjheseletsa laser ka letsoho, ha ho hlokahale hore ho be le tafole e nepahetseng ya ho tjheseletsa, disebediswa tse fokolang, ditjeho tse tlase tsa ho tsamaisa thepa le ho di lokisa, le tshebetso ya ditjeho tse phahameng;

3. Pholosa mosebetsi. Ho tjheseletsa ka laser ka letsoho ho potlakile, ho potlakile ho feta ho tjheseletsa ha setso, mme seam sa weld kamora ho tjheseletsa se boreledi ebile se setle, se fokotsa tshebetso ya ho sila ka morao, ho boloka nako le ditjeho;

4. Boleng bo botle. Laser welding workpiece ha e na deformation, ha ho na lebadi tjheseletsa, le tjheseletsa e matla;

5. Tšireletso ea tšireletso. E na le ts'ebetso ea ts'ireletso ea ts'ireletso ea ho kopana ho thibela leseli hore le se ke la hlahisoa ka phoso, le ho etsa bonnete ba hore leseli le cheselitsoe ka mor'a ho kopana le tšepe. E na le likhalase tsa laser tse sireletsang, tse lokelang ho apesoa ha li cheseletsa. Ho netefatsa polokeho.

Mochini o ts'oaretsoeng ka letsoho oa seipone o na le mefuta e ka bang 6 ea matheba a bobebe, a ka tlatsang li-welding tsa fillet, welding vertical, welding ea tailor, le stitch welding, le ho arabela mefuta e fapaneng ea likopo tsa kopo.

Libaka tsa kopo tse ka sehloohong

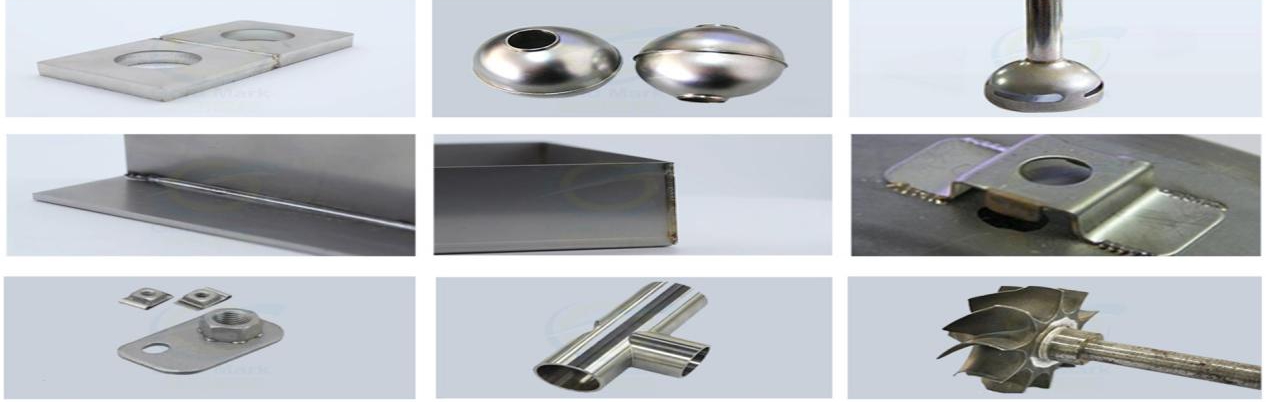

Ho lokisa litšepe ka kichineng le liphaposing tsa ho hlapela, lifti, lishelefo, hardware, thepa ea kaho, mamati le lifensetere, likoahelo tsa manhole, li-interceptors tsa mobu, mesebetsi ea matsoho le liindasteri tse ling, le tjheseletsa ea laser ea lakane le thepa ea liphaephe liindastering tse joalo ka mechini ea boenjiniere le ho tsamaisa likepe.

Lintlha tse chesehang

Tšepe ea carbon, tšepe e sa hloekang, motsoako oa aluminium, koporo, koporo, poleiti ea pickling, poleiti ea galvanized, poleiti ea tšepe ea silicon, poleiti ea electrolytic, alloy ea titanium, alloy ea manganese le lisebelisoa tse ling tsa tšepe.

Jinan Gold Mark CNC Machinery Co., Ltd.ke khoebo ea indasteri ea theknoloji e phahameng e ikhethang ho etsa lipatlisiso, ho etsa le ho rekisa mechini ka tsela e latelang: Laser Engraver, Fiber Laser Marking Machine, CNC Router. Lihlahisoa li 'nile tsa sebelisoa haholo ka boto ea lipapatso, mesebetsi ea matsoho le ho bōpa, mehaho, tiiso, letšoao, ho betla lehong le ho betla, ho khabisa majoe, ho khaola letlalo, liindasteri tsa liaparo, joalo-joalo. Motheong oa ho monya thekenoloji e tsoetseng pele ea machabeng, re fa bareki tlhahiso e tsoetseng pele ka ho fetisisa le ts'ebeletso e phethahetseng ea kamora thekiso. Lilemong tsa morao tjena, lihlahisoa tsa rona ha li rekisoe Chaena feela, empa hape ho ea fihla Asia Boroa-bochabela, Bochabela bo Hare, Europe, Amerika Boroa le Limmaraka tse ling tsa mose ho maoatle.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Nako ea poso: Feb-21-2022