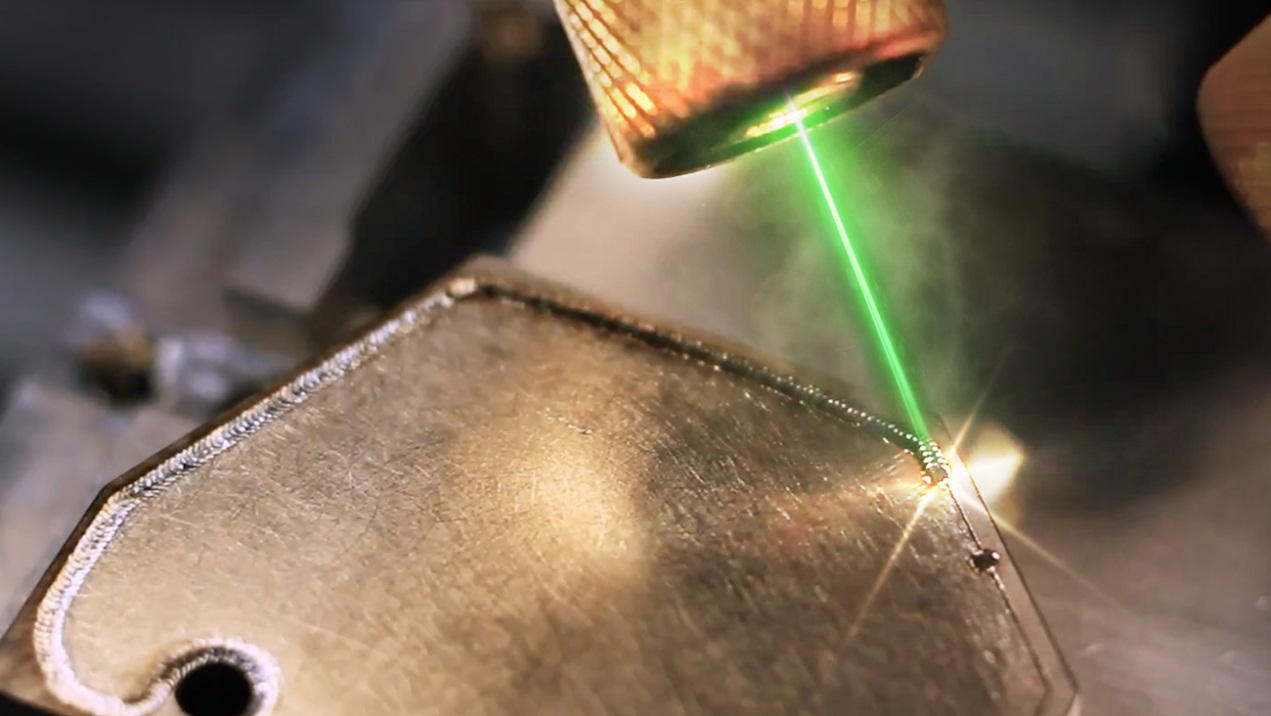

Laser tjheseletsa mochini e le mofuta o mocha oa thepa ea ho sebetsa, butle-butle nkeloa sebaka thepa ea setso tjheseletsa, ho pharaletseng sebelisoa liindasteri tse fapa-fapaneng, ka tshebetso ya ho sebelisa laser tjheseletsa mochini hangata kopana le maemo a sa tšoaneng, bakeng sa metsoalle e se nang phihlelo, hangata tsielehile ha ba tsebe joang. ho rarolla. Ha e le hantle, ho na le mathata a mang ao re ntseng re ka a rarolla ka bobona, kahoo re ka rarolla mathata a tloaelehileng joang ha ho sebelisoa mochine oa welding oa laser? E latelang latela Gold Mark laser ho bona.

1 ho fafatsa mollo o tsoang ka sekoting.

1, khatello e nyane, hangata e pakeng tsa khatello ea moea ea 3-4, ho latela tafole ea khatello ea moea sebakeng sa welder e tla hlola.

2, valve ea buffer e ile ea koaheloa ka ntle ho fapana le oache ho fokotsa ho otla ha buffer.

3, nako ea pele ho khatello e khuts'oane haholo, fetola nako ea pele ho khatello, ho latela bolelele ba seterouku sa electrode ho fetola nako ea pele ho khatello, (motsotso oa pele ho khatello ke motsamao o theohelang oa electrode ho fihlela motsotsong oa ho hatella workpiece discharge), ha seterouku se ntse se hola le ho feta nako ea pele ho khatello.

4, hlahloba hore na workpiece ke mafome, oli, haeba maemo ana a mabeli maikutlo a lahla mafome phela oli;.

5, joalo ka ha terata ea welding, ha ho na oli kapa mafome ho lekola ponahalo ha e na phofo e ngata haholo.

2 tjheseletsa ha e na matla.

1, ea hona joale ke e nyenyane haholo kapa tjheseletsa nako e khutšoanyane haholo, hangata mali oksijene probe tjheseletsa tsela ho khetha nako e khutsoanyane phahameng hona joale tjheseletsa, e le hore molemo ka ho fetisisa tjheseletsa phello e ka tjheseletsa. Ho ea ka qeto ea ho tjheseletsa workpiece tjheseletsa motsotso, hangata tjheseletsa motsotso tšoara ka maqhubu a 2-5 (50 maqhubu a motsotsoana, maemo a khetho ea motsotso ona tjheseletsa ha se lerata mojaro khetho ea boemo), tjheseletsa motsotso e behiloeng ka mor'a ho lokisa tjheseletsa. hona joale, nako e khuts'oane ea ho cheselletsa, e kholoanyane ea hona joale ea welding.

2, tjheseletsa workpiece ponahalo ea mafome, oli, kapa hula phofo .

3, mochini oa tjheseletsa ha o chese kapa ha o na matla: hlahloba fuse ea mohala oa motlakase, joalo ka ha fuse e sa robeha; hlahloba boto ea potoloho ho laola mohala hase ponahalo e oeleng; hlahloba fuse ea molaoli; letheba tjheseletsa mochine o na le motlakase, molaoli o tloaelehile, ha a sebetse, hlahloba fapoha leoto, joalo ka fapoha leoto hase bothata, hlahloba leoto fapoha khokahanyo mola; ts'ebetso ea mochini oa tjheseletsa ea letheba ha e tloaelehe, ho theoha ha switjha ea leoto ha e sebetse, phahamisa sesebelisoa sa leoto hanyenyane, hlahloba phetoho ea leoto; silindara tobetsa fatše, eseng phahamisa, hlahloba silindara le eleketrode slide molamu ha se hlephileng ho oa; transformer mocheso kaofela.

Jinan Gold Mark CNC Machinery Co., Ltd. ke indasteri ea theknoloji e phahameng e sebetsanang le ho etsa lipatlisiso, ho etsa le ho rekisa mechine ka tsela e latelang: Laser Engraver, Fiber Laser Marking Machine, CNC Router. Lihlahisoa li 'nile tsa sebelisoa haholo ka boto ea lipapatso, mesebetsi ea matsoho le ho bōpa, mehaho, tiiso, letšoao, ho betla lehong le ho betla, ho khabisa majoe, ho khaola letlalo, liindasteri tsa liaparo, joalo-joalo. Motheong oa ho monya thekenoloji e tsoetseng pele ea machabeng, re fa bareki tlhahiso e tsoetseng pele ka ho fetisisa le ts'ebeletso e phethahetseng ea kamora thekiso. Lilemong tsa morao tjena, lihlahisoa tsa rona ha li rekisoe Chaena feela, empa hape ho ea fihla Asia Boroa-bochabela, Bochabela bo Hare, Europe, Amerika Boroa le Limmaraka tse ling tsa mose ho maoatle.

Nako ea poso: Apr-19-2021