Lisebelisoa tsa bongaka ke lisebelisoa tse nepahetseng 'me likarolo tse ngata tsa ka hare le tsona li nepahetse haholo. Hangata lisebelisoa tsa bongaka li hloka sterility mme ha ho na lik'hemik'hale tse lokelang ho ameha, ha lisebelisoa tsa bongaka li le nyenyane 'me li hloka li-microscopic soldering tse nang le li-welds tse boreleli tse sa senyeng likaroloana. Mekhoa e tloaelehileng ea li-welding e ka kenya lintho tsa lik'hemik'hale ka har'a lisebelisoa le lisebelisoa, tse ka amang ho nepahala. Laser welding, e le mokhoa o sa amaneng le welding, o loketse ka ho khetheha bakeng sa tlhahiso ea lihlahisoa tse joalo tsa lisebelisoa tsa bongaka.Mechini ea tjheseletsa ea lasere hlahisa mocheso o fokolang mme e ka sebelisoa haufi le litiiso tsa polymer, likhalase le litiiso tsa tšepe, likarolo tse cheselitsoeng le li-circuits tsa elektroniki. LatelaKHAUTA LETŠOAho bona hore na mechini ea welding ea laser e sebelisoa joang lisebelisoa tsa bongaka.

Bongata ba lisebelisoa tsa bongaka tse sa kenngoeng ke 304L tšepe e sa jeleng paate. Ho bonolo ho tjheseletsa, ha e qhekelle ebile ha e ratehe ho bola sebakeng sa weld joalo ka lisebelisoa tse phahameng tsa tšepe tse se nang k'habone. Li-alloys tse ling ka linako tse ling li sebelisoa, joalo ka litšepe tse thata tse phahameng joalo ka 440C kapa 430, 'me ka linako tse ling titanium Ti6-4, tseo kaofela li ka chesehang hafeela ho sebelisoa mokhoa o nepahetseng oa tjheseletsa le motsoako oa alloy.

Lisebelisoa tsa ho buoa, joalo ka lisebelisoa tsa biopsy, li sebelisa laser welding ho hokela lithakhisa ho likaroloana le ho tjheseletsa likarolo ho lead. Lisebelisoa tsa meno li sebelisa laser welding bakeng sa mefuta e mengata ea lisebelisoa, ho tloha ho sila ho ea ho ho etsoa ha ntlo ea sesebelisoa. Likarolo tse nyane tsa methapo ea kutlo li chesetsoa ka laser nakong ea kopano, 'me li-welds tse boreleli, tse sa fetoheng lia hlokahala lisebelisoang tse bonolo joalo. Li-stents, li-catheter tsa pelo, le lisebelisoa tse ling tsa kalafo ea arterial li bokelloa ho sebelisoa welding ea laser. Ho thusa tlhahlobo ea X-ray, matšoao a macha a X-ray opaque a eketsoa likarolong. Hangata li-endoscopes tse thata li entsoe ka li-tubes tsa tšepe tse sa hloekang, tse tiisitsoeng ka laser pakeng tsa li-tubes le sebakeng sa coupler. Maemong a mangata, laser welding e fella ka li-welds tse boreleli, tse se nang porosity, tse pheta-phetoang, tse ka sebelisoang moo ho khopameng ho fokolang ho hlokahalang, le moo autoclaving e hlokahalang.

Li-lasers tsa pulsed YAG ke khetho e ntle ka ho fetisisa bakeng sa lisebelisoa tsa bongaka tsa welding. Li na le matla a phahameng a phahameng, li hlahisa mocheso o fokolang, li ka rarolla mathata ka li-alloys tse fapaneng, 'me li ka etsa ts'ebetso e ntle ha li ntse li boloka botebo bo phahameng ba fusion. Fiber optic transmission ke eona e sebelisoang ka ho fetisisa e le boholo bo sa fetoheng ba sebaka le kabo ea matla ka bobeli e thusa ho tlatsa likheo tse fapaneng ka ho sebelisa manonyeletso a fillet le butt ho fumana bophara bo botle ba fusion core ha u cheselletsa bongata bo boholo. Hape sebaka se senyenyane sa libaka tse shebaneng le sona se bolokiloe ka har'a 40-60um. Bakeng sa lisebelisoa tse ngata tse hlokang ho etsoa kapele, li-lasers tse tsoelang pele le li-laser tsa YAG tsa mofuta oa super-mode ke khetho e ntle ka ho fetisisa.

Ho na le lits'ebetso tse ling tse ngata bakeng sa welding ea laser lekaleng la lisebelisoa tsa bongaka. Ntle le theknoloji ea welding ea laser e sebelisoang tlhahisong ea lisebelisoa tsa bongaka, ho na le mekhoa e meng e mengata e mecha ea ho sebetsa ka laser e nang le bokhoni bo boholo ho etseng lisebelisoa tsa bongaka. Laser welding e fihlela litlhoko tsa tlhahiso le tlhahiso ea lisebelisoa tsa bongaka ka lebaka la mokhoa oa eona oa ho tjheseletsa o sa amaneng le batho. Ka nako e ts'oanang, theknoloji ea welding ea laser e ka boleloa hore e tlatselitse haholo ho nts'etsopele ea lisebelisoa tsa bongaka ka lebaka la hore e hlahisa hoo e batlang e se manya kapa lithōle nakong ea ts'ebetso ea ho cheselletsa 'me ha ho hlokahale hore ho eketsoe likhomaretsi.

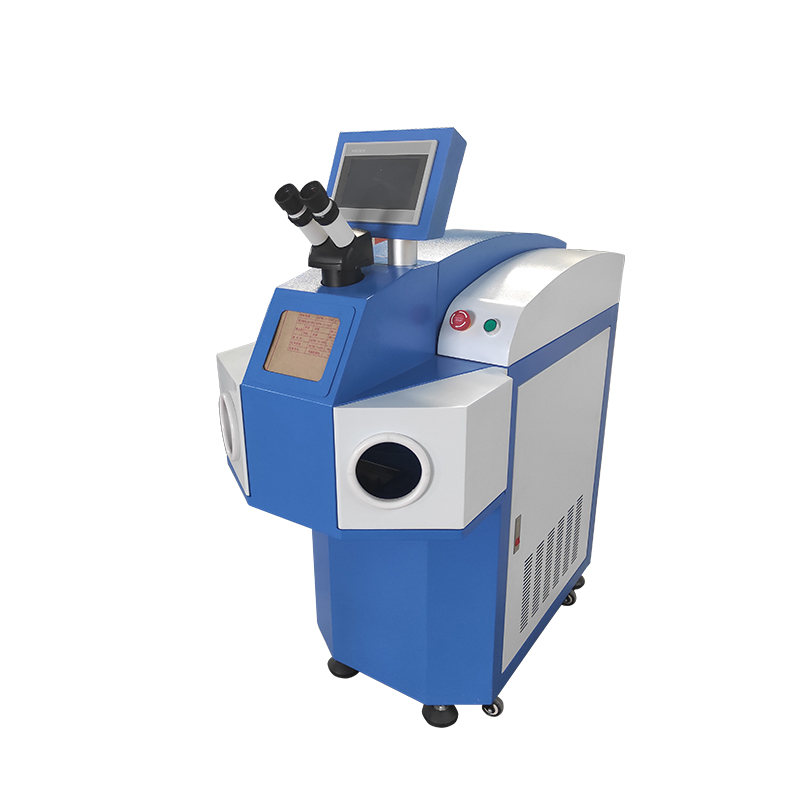

Jinan Gold Mark CNC Machinery Co., Ltd.ke khoebo ea indasteri ea theknoloji e phahameng e ikhethang ho etsa lipatlisiso, ho etsa le ho rekisa mechini ka tsela e latelang: Laser Engraver, Fiber Laser Marking Machine, CNC Router. Lihlahisoa li 'nile tsa sebelisoa haholo ka boto ea lipapatso, mesebetsi ea matsoho le ho bōpa, mehaho, tiiso, letšoao, ho betla lehong le ho betla, ho khabisa majoe, ho khaola letlalo, liindasteri tsa liaparo, joalo-joalo. Motheong oa ho monya thekenoloji e tsoetseng pele ea machabeng, re fa bareki tlhahiso e tsoetseng pele ka ho fetisisa le ts'ebeletso e phethahetseng ea kamora thekiso. Lilemong tsa morao tjena, lihlahisoa tsa rona ha li rekisoe Chaena feela, empa hape ho ea fihla Asia Boroa-bochabela, Bochabela bo Hare, Europe, Amerika Boroa le Limmaraka tse ling tsa mose ho maoatle.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Nako ea poso: Oct-25-2021