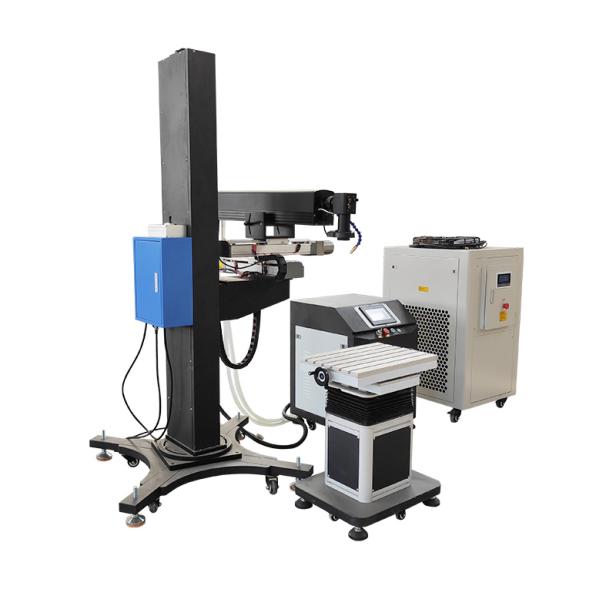

Mochini oa tjheseletsa oa lasere sebelisoa tšimong ea ho cheselletsa, 'me ke e' ngoe ea lintlha tsa bohlokoa tsa ts'ebeliso ea theknoloji ea laser material processing. Ho ea ka mokhoa oa eona oa ho sebetsa, o ka aroloa ka mochine oa ho tjheseletsa hlobo oa laser, mochine oa ho tjheseletsa oa laser, le mochine oa ho tjheseletsa letheba, mochine oa tjheseletsa oa fiber laser, joalo-joalo melemo ea mochine oa ho tjheseletsa laser ke ofe?

- Ø Melemo

1. Ka mor'a ho lebisa tlhokomelo ea laser, matla a matla a phahame. Kamora hore laser ea boemo bo tlase ba matla a holimo e tsepame, bophara ba sebaka se shebileng bo nyane haholo.

2. Lebelo la welding la laser le potlakile, botebo bo boholo, 'me deformation e nyane. Ka lebaka la matla a mangata a matla, likoti tse nyenyane li thehoa ka thepa ea tšepe nakong eamokhoa oa ho tjheseletsa laser, 'me matla a laser a fetisetsoa karolong e tebileng ea workpiece ka likoti tse nyenyane,' me ho na le ho fokotseha ho fokolang ka mahlakoreng. Lebelo le potlakile, 'me sebaka sa welding ka nako ea yuniti se seholo.

3. Karo-karolelano ea botebo-ho ea ho bophara ba welding e kholo, matla a khethehileng a nyenyane, sebaka se amehileng ke mocheso se senyenyane, 'me deformation ea welding e nyenyane. E loketse ka ho khetheha bakeng sa ho tjheseletsa ha likarolo tse nepahetseng le tse sa utloisiseng mocheso, tse ka qobang ho sebetsa ka mor'a weld orthopedic le bobeli.

4. E ka chesetsoa mocheso oa kamore kapa tlas'a maemo a khethehileng, 'me thepa ea ho tjheseletsa e bonolo.

5. E ka cheselletsa thepa ea refractory, joalo ka titanium, quartz, joalo-joalo, 'me e ka cheselletsa lisebelisoa tsa lisebelisoa tse fapaneng, joalo ka koporo le tantalum, litšepe tse peli tse nang le thepa e fapaneng ka ho felletseng li kopantsoe hammoho,' me phello e ntle.

6. Micro-welding e ka etsoa. Ka mor'a hore lebone la laser le tsepame, ho ka fumanoa sebaka se senyenyane, 'me se ka behoa hantle, se ka sebelisoang ho kopanya lisebelisoa tse nyenyane le tse nyenyane ka tlhahiso ea boima bo ikemetseng. Hase feela katleho ea tlhahiso e ntlafetseng haholo, empa hape sebaka se amehileng ke mocheso se senyenyane 'me motsoako oa solder ha o na tšilafalo, e leng ho ntlafatsang haholo boleng ba welding.

7. E ka cheselletsa likarolo tseo ho leng thata ho fihla ho tsona le ho kenya tšebetsong welding ea sebaka se selelele e sa amaneng le batho, e nang le maemo a bonolo haholo.

8. Ka kakaretso, ha ho na tšepe ea ho tlatsa e kenngoa. Haeba e sirelelitsoe ka ho feletseng ka khase e sa sebetseng, weld ha e na tšilafalo ea sepakapaka

9. The tjheseletsa tsamaiso e haholo tenyetsehang le bonolo ho automate.

10.Mochini oa tjheseletsa oa laserLaser welding e ts'oana le tjheseletso ea elektrone beam ka likarolo tse ngata, 'me boleng ba eona ba ho tjheseletsa bo tlase hanyane ho feta ho tjheseletsa beam ea elektrone, empa sefate sa elektrone se ka fetisoa feela ka vacuum, kahoo welding e ka etsoa feela ka vacuum, le theknoloji ea welding ea laser e ka sebelisoa. libakeng tse ngata tse fapaneng tsa mosebetsi.

Jinan Gold Mark CNC Machinery Co., Ltd.ke khoebo ea indasteri ea theknoloji e phahameng e ikhethang ho etsa lipatlisiso, ho etsa le ho rekisa mechini ka tsela e latelang: Laser Engraver, Fiber Laser Marking Machine, CNC Router. Lihlahisoa li 'nile tsa sebelisoa haholo ka boto ea lipapatso, mesebetsi ea matsoho le ho bōpa, mehaho, tiiso, letšoao, ho betla lehong le ho betla, ho khabisa majoe, ho khaola letlalo, liindasteri tsa liaparo, joalo-joalo. Motheong oa ho monya thekenoloji e tsoetseng pele ea machabeng, re fa bareki tlhahiso e tsoetseng pele ka ho fetisisa le ts'ebeletso e phethahetseng ea kamora thekiso. Lilemong tsa morao tjena, lihlahisoa tsa rona ha li rekisoe Chaena feela, empa hape ho ea fihla Asia Boroa-bochabela, Bochabela bo Hare, Europe, Amerika Boroa le Limmaraka tse ling tsa mose ho maoatle.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Nako ea poso: Aug-02-2022