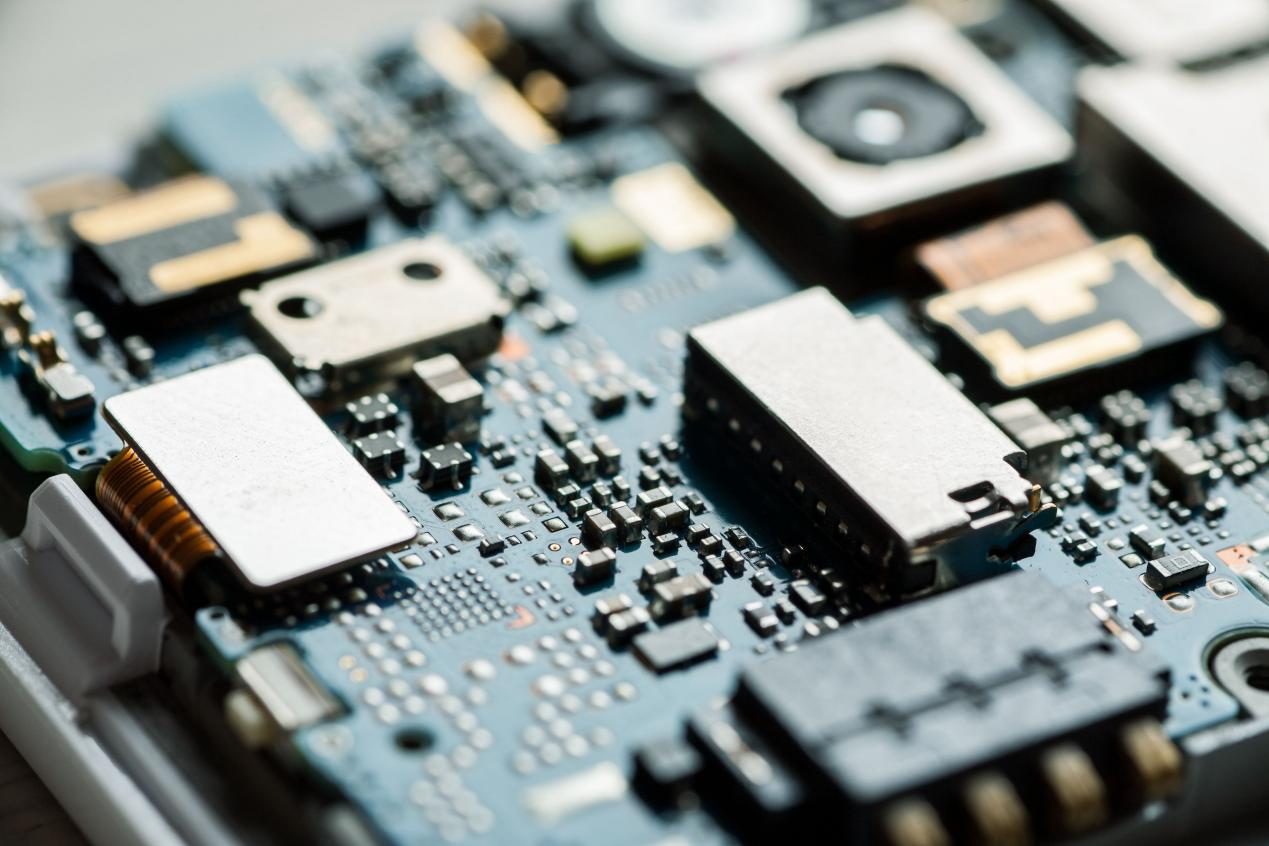

Ngokuduma kwee-smartphones, iiTV zephaneli ecaba kunye nezinye izixhobo, intengiso ye-elektroniki yabathengi ibone ukukhula okungazange kubonwe ngaphambili. Ukhuphiswano oluhlala lukhula lukhokelele ushishino lokwenziwa kwe-electronics ukubeka iimfuno eziphezulu kwiinkqubo zemveliso. Iindlela zokucubungula zemveli ziye zanda ngokungakwazi ukuhlangabezana neemfuno zeenkqubo zanamhlanje. Umgangatho wemveliso engazinzanga, iinxalenye ezinyibilikisiweyo, ubunzima bokwenza ii-nuclei eziqhelekileyo, kunye namaxabiso aphantsi esivuno abe yingxaki kubavelisi. Ukuvela kwewelding laseritekhnoloji idlale indima enkulu kwinkqubo yokuveliswa kweemveliso ze-elektroniki eziphezulu, zombini ngokubhekiselele kumthamo wemveliso kunye nokuphucula umgangatho.

Okwangoku, i-laser welding kwimveliso ye-electronics isetyenziswa ikakhulu kwitekhnoloji ye-welding echanekileyo, echanekileyoukuwelda indawoitekhnoloji ine-deformation encinci ye-thermal, indima yendawo kunye nendawo yolawulo oluchanekileyo, umgangatho ophezulu we-welding, ukukwazi ukufikelela kwi-welding ye-heterogeneous material, ukufezekisa lula ukuzenzekelayo kunye nezinye iingenelo, zingasetyenziswa kwiimveliso ze-elektroniki kwiqokobhe, ikhaka, Isidibanisi se-USB, i-patch conductive, njl., kodwa ukuwelda izinto ezahlukeneyo, imfuneko yokusebenzisa iindlela ezahlukeneyo ze-welding. LandelaUPHAWU LWEGOLIDEukufunda ngakumbi malunga noku kulandelayo.

Indlela ye-laser echanekileyo ye-welding ye-anti-material ephezulu

Xa udibanisa izinto ezibonisa kakhulu njenge-aluminiyam kunye nobhedu, iifom ze-welding ezahlukeneyo zinempembelelo enkulu kumgangatho wokuwelda. Ukusebenzisa i-laser waveform ene-spike yangaphambili kunokwaphula umqobo wokubonisa okuphezulu. Amandla aphezulu aphezulu ngokukhawuleza angatshintsha ngokukhawuleza imeko yentsimbi kwaye aphakamise ubushushu bawo kwindawo yokunyibilika, ngaloo ndlela ukunciphisa ukubonakaliswa kwendawo yesinyithi kunye nokuphucula ukusetyenziswa kwamandla. Ukongeza, ekubeni izinto ezifana nobhedu kunye ne-aluminium ziqhuba ubushushu ngokukhawuleza, ukubonakala kwejoyinti ye-solder kunokulungiswa ngokusebenzisa i-wave-drop-drop waveform.

Kwelinye icala, inqanaba lokufunxa kwelaser yezinto ezifana negolide, isilivere, ubhedu kunye nentsimbi yehla ngokunyuka kwamaza, kwaye kobhedu, isantya sokufunxa sobhedu sisondele kuma-40% xa i-laser wavelength ingama-532 nm. Ukuthelekiswa kweempawu ze-laser ye-infrared kunye ne-laser eluhlaza kubonisa ukuba ubungakanani bendawo ye-laser ye-infrared bukhulu, ubunzulu be-focal bufutshane, kwaye izinga lokufunxa kobhedu liphantsi; ubungakanani bendawo yelaser eluhlaza buncinci, ubunzulu obugxile bubude, kwaye izinga lokufunxa kobhedu liphezulu. I-laser ye-infrared kunye ne-green laser pulse spot welding yobhedu, ngokulandelelana, inokufunyanwa ukuba ukuwelda kwe-infrared laser emva kobungakanani beendawo zokuwelda ezingahambelaniyo, ngelixa i-laser green welding joints size more uniform, ubunzulu obungaguqukiyo, umphezulu ogudileyo. Umphumo we-welding uzinzile ngakumbi nge-laser eluhlaza, kwaye amandla aphezulu afunekayo aya kuba ngaphezu kwesiqingatha se-laser ye-infrared.

Laser ukuchaneka indawo welding indlela yezixhobo sheet metal obhityileyo

I-laser ye-millisecond yesiko ithanda ukungena kunye namalungu amakhulu xa kuthungelwa izinto zentsimbi ezicekethekileyo, ngelixa izinto eziguquguqukayo eziphezulu zihlala zineendawo ezigqabhukileyo kunye ne-welds yobuxoki ngenxa yokungazinzi kwazo kunye nokufunxa okuphantsi kokukhanya kwelaser kwimeko eqinileyo. Ukuze kulungiswe ipleyiti ebhityileyo kunye nobunzima obuphezulu bokuwelda isinyithi, ngokusebenzisa i-fiber laser QCW / CW imowudi ye-analog kunye nokumodareyitha kwedijithali, ngokulandelelana, qalisa kanye ukufezekisa imveliso ye-N pulse, ngamandla amancinci ukufezekisa inqaku elinye le-multi-pulse welding. .

Indlela ye-laser yokuchaneka kwendawo yokuwelda kwizinto ezahlukeneyo

I-laser welding ye-plate ebhityileyo yezinto ezingafaniyo ichaphazeleka kakhulu kwi-welding yobuxoki, iintanda, kunye namandla adibeneyo aphantsi ngenxa yomahluko omkhulu kwiipropathi ezibonakalayo, ukunyibilika okuphantsi, kunye namathuba aphezulu okuvelisa iikhompawundi ezinqabileyo, ezinciphisa kakhulu iipropathi zoomatshini intloko weld. I-laser ye-nanosecond enomgangatho ophezulu we-beam ikhethiwe ukucinezela ukubunjwa kwe-intermetallic compounds nge-high speed scanning method kunye nokulawulwa okuchanekileyo kwegalelo lobushushu ukuqonda i-lap joint yamacwecwe amancinci eentsimbi ezingafaniyo kunye nokuphucula ukubunjwa kwe-weld kunye neempawu zomatshini.

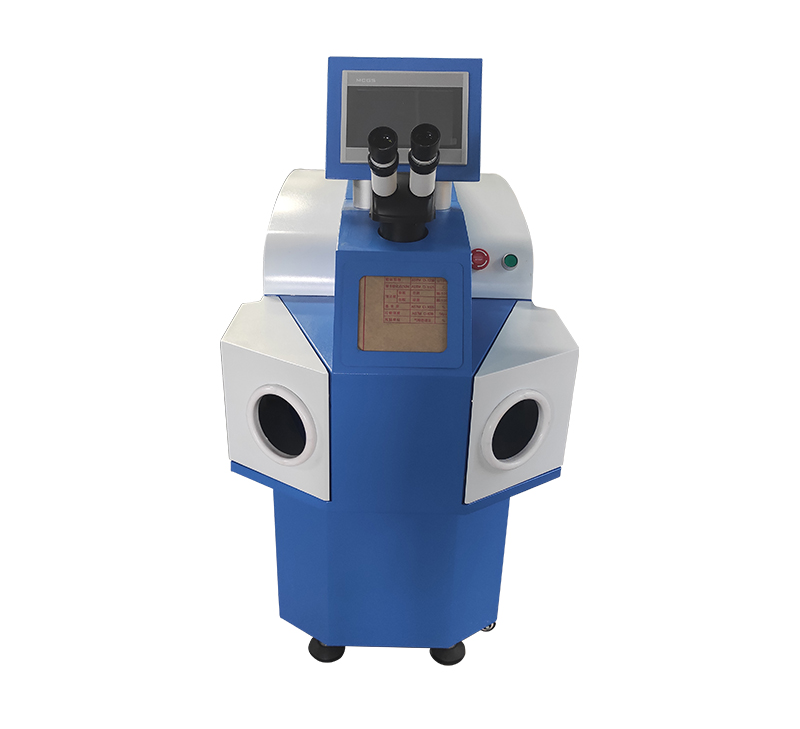

IJinan Gold Mark CNC Machinery Co., Ltd. lishishini lobugcisa obuphezulu obukhethekileyo kuphando, ukuvelisa kunye nokuthengisa oomatshini ngolu hlobo lulandelayo: I-Laser Engraver, iFiber Laser Marking Machine, i-CNC Router. Iimveliso zisetyenziswe ngokubanzi kwibhodi yentengiso, ubugcisa kunye nokubumba, i-architecture, i-seal, ilebula, ukudweba imithi kunye nokukrola, umhlobiso wamatye, ukusika kwesikhumba, amashishini eengubo, njalo njalo. Kwisiseko sokufunxa itekhnoloji ephezulu yamazwe ngamazwe, sibonelela abathengi ngeyona mveliso iphambili kunye nenkonzo egqibeleleyo emva kokuthengiswa. Kwiminyaka yakutshanje, iimveliso zethu azithengiswanga kuphela e-China, kodwa nakwi-Asia-mpuma ye-Asia, kuMbindi mpuma, eYurophu, eMzantsi Melika nakwezinye iiMarike zaphesheya.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Ixesha lokuposa: Aug-27-2021