Ngokuphumelela okuqhubekayo kobuchwepheshe belaser bale mihla, ukwanda kancinci kancinci kobuchwepheshe belaser, kunye nokuphuculwa nophuhliso lwamashishini anxulumeneyo, indawo yokusetyenziswa kobuchwephesha belaser iyaqhubeka nokukhula. Okwangoku, ayingomashishini aphezulu kuphela kunye namashishini okulungisa ukuchaneka asetyenziswa ngokubanzi, kodwa ngakumbi nangakumbi itekhnoloji yelaser yale mihla isetyenziswa kwiinkalo zemveli zokusetyenzwa; Itekhnoloji yeLaser nayo ineenkalo ezininzi ezithile. Umatshini wokusika we-CO2 we-laser lisebe lobuchwephesha be-laser. Ngaba uyazi ukuba yeyiphiamasimi asebenzisa iteknoloji yokusika i-CO2 laser?

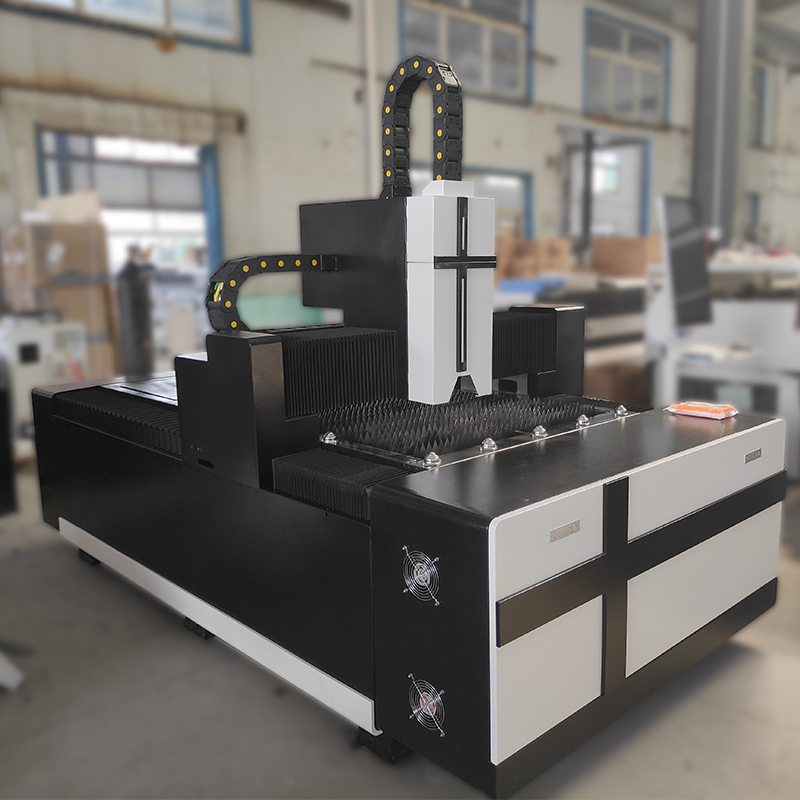

Umatshini wokusika weLaserisetyenziswe ngokubanzi kwindawo yoshishino, ngakumbi kwimveliso ye-electromechanical processing kunye neshishini lokuvelisa.

1. Ukusika umphunga

I-workpiece iphakama kwiqondo lokushisa ngaphezu kwendawo yokubilisa phantsi kokufudumeza kwe-laser

i-beam, inxalenye yempahla ijika ibe ngumphunga, kwaye inxalenye ephunyukileyo ivuthelwe ukusuka ezantsi komthungo wokusika njenge-ejecta. Ifuna ubuninzi bamandla obuphezulu be-108w / cm2, amaxesha angama-10 amandla afunwa ngumatshini wokusika onyibilikayo. Le ndlela ifanelekile ukucubungula iinkuni, ikhabhoni kunye nezinye iiplastiki ezingenako ukunyibilika.

2. Nyibilika ukusika

Xa uxinano lwamandla ombane welaser ludlula ixabiso elithile, luya kuphuma ngumphunga kwindawo yokusebenza ukwenza imingxunya, emva koko igesi encedisayo i-coaxial ngomqadi iya kugxotha imathiriyeli etyhidiweyo ejikeleze imingxuma kwaye yenze izikhewu.

3. Ioksijini incedise ukunyibilikisa ukusika

Ukuba i-oksijeni okanye enye igesi esebenzayo isetyenziselwa ukutshintsha igesi ye-inert esetyenziselwa ukunyibilika kunye nokusika, omnye umthombo wokushisa ngaphandle kwamandla e-laser uya kuveliswa ngexesha elifanayo ngenxa yokutshisa i-matrix eshushu. Le nkqubo iyinkimbinkimbi, kwaye iipleyiti ezininzi zetsimbi zikolu hlobo lokusika. I-oksijini encediswa ukusika ukunyibilika kunemithombo emibini yamandla, kwaye ubudlelwane phakathi kwamandla e-laser kunye nesantya sokusika kufuneka buphathwe ngexesha lokusika.

4. Lawula ukusika i-fracture

Xa indawo encinci ye-brittle material ifudunyezwa yi-laser beam, i-gradient ye-thermal kunye ne-deformation enzima elandelayo ye-mechanical deformation iya kukhokelela ekuqhekekeni. Kolu hlobo lokusika, amandla e-laser kunye nobungakanani bendawo kufuneka ilawulwe ikakhulu.

Umatshini wokusika weLaseryimveliso engene kuphuhliso lwesantya esiphezulu kwaye isetyenziswa ngokubanzi. Ekuqhubeni nasekuveliseni amashishini amashishini, idlale indima ekukhuthazeni uphuhliso loqoqosho lwesizwe. Iimpawu zayo ezingenakuphinda zibuyiselwe kwindawo yoshishino ziya kukhuthaza ukusetyenziswa ngokukhawuleza nangokubanzi kobu buchwepheshe kumashishini oshishino aseTshayina.

IJinan Gold Mark CNC Machinery Co., Ltd.lishishini lobugcisa obuphezulu obukhethekileyo kuphando, ukuvelisa kunye nokuthengisa oomatshini ngolu hlobo lulandelayo: I-Laser Engraver, iFiber Laser Marking Machine, i-CNC Router. Iimveliso zisetyenziswe ngokubanzi kwibhodi yentengiso, ubugcisa kunye nokubumba, i-architecture, i-seal, ilebula, ukudweba imithi kunye nokukrola, umhlobiso wamatye, ukusika kwesikhumba, amashishini eengubo, njalo njalo. Kwisiseko sokufunxa itekhnoloji ephezulu yamazwe ngamazwe, sibonelela abathengi ngeyona mveliso iphambili kunye nenkonzo egqibeleleyo emva kokuthengiswa. Kwiminyaka yakutshanje, iimveliso zethu azithengiswanga kuphela e-China, kodwa nakwi-Asia-mpuma ye-Asia, kuMbindi mpuma, eYurophu, eMzantsi Melika nakwezinye iiMarike zaphesheya.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Ixesha lokuposa: Jul-22-2022