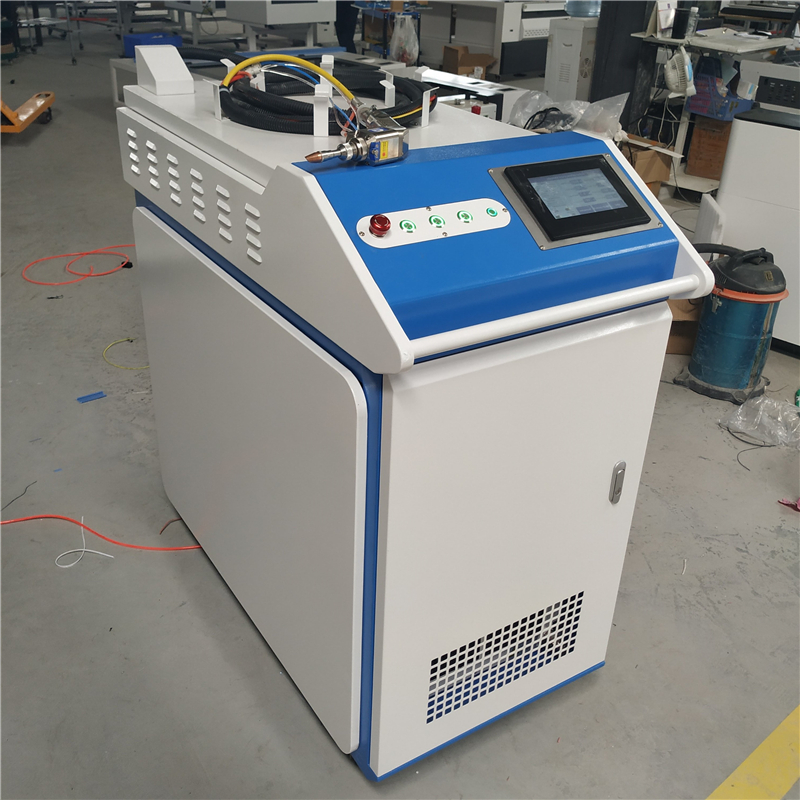

Umatshini wokuwelda welaser ophathwa ngesandlaokwangoku sesona sixhobo sokuwelda kushishino lwesinyithi, abahlobo abaninzi ekusebenzeni komatshini wokuwelda we-laser ophathwayo phambi koqeqesho olufanelekileyo lobuchwephesha, kwaye abazi indlela yokusebenzisa ngokufanelekileyo kwaye zeziphi iimbono zokusetyenziswa. Ukuze siqinisekise ukhuseleko kunye nokukhuselwa umatshini welding laser, kufuneka siqonde umatshini welding laser ephathwayo xa usebenzisa zeziphi izilumkiso, landelaUPHAWU LWEGOLIDEfunda lo mxholo ulandelayo ukuze uqonde!

1. Kufuneka ugqoke iiglasi ezichasene ne-radiation, iimaski, kufuneka unxibe iimpahla ezikhuselekileyo zokukhusela ukuqinisekisa ukhuseleko lwemveliso yabasebenzi, zonke iingozi zokhuseleko ezibangelwa ukungahambelani nenkampani ayinanto yokwenza.

2. Ukuthintela ukusetyenziswa komhlaba oqhelekileyo kunye nomatshini we-arc welding (i-argon arc welding, i-welding, i-carbon dioxide ekhuselwe umshini we-welding) ukukhusela i-reflux yangoku ichaphazela amacandelo e-laser.

3. Intloko ye-welding kufuneka ingahambelani nayo nayiphi na inxalenye yomzimba ngexesha lokusetyenziswa. Intloko ye-welding ayikwazi ukubekwa phantsi, soloko ubeke ingqalelo ekulawuleni uthuli.

4. Nika ingqalelo kwi-fiber optic bellows bellows radius engekho ngaphantsi kwe-20CM ngexesha lenkqubo ye-welding, ukuze ungatshisi i-fiber.

5. Kwimeko nayiphi na ingozi, ngokukhawuleza cofa iqhosha lokumisa likaxakeka kwaye uqhagamshelane nabasebenzi bethu ukubonisa imeko.

6. Ukuba uyeka ukusebenza okwethutyana, nceda nqakraza u-"Stop" ukungena kwi-standby state, okanye uyeke ukusebenza emva komsebenzi, nceda ucofe u-"Stop" ukungena kwimeko yokulinda kwaye ucime izixhobo.

7. Xa utshintshe i-lens yokukhusela okanye ukhangele intloko ye-welding, amandla ezixhobo kufuneka acinywe.

8. Umatshini wokupholisa useto lobushushu bamanzi, kwaye umehluko weqondo lokushisa phakathi kweqondo lokushisa alikho ngaphezu kwe-10 degrees! Ubushushu bamanzi bucetyiswa ukuba bubekwe ku 26℃-30℃ ehlotyeni kunye ne 20℃-22℃ ebusika. Ukwahlukana kweqondo lokushisa phakathi kwekhabhinethi kuya kubangela ukuba ifowuni ye-laser idibanise kwaye ibangele umonakalo kwi-laser. Xa ubushushu begumbi bungaphantsi kwe-4 ℃, kufuneka uthathe amanyathelo achasene neqhwa, unokongeza i-glycol kunye namanzi acocekileyo kwitanki yamanzi emva kokuxuba kwi-1: 3.

IJinan Gold Mark CNC Machinery Co., Ltd.lishishini lobugcisa obuphezulu obukhethekileyo kuphando, ukuvelisa kunye nokuthengisa oomatshini ngolu hlobo lulandelayo: I-Laser Engraver, iFiber Laser Marking Machine, i-CNC Router. Iimveliso zisetyenziswe ngokubanzi kwibhodi yentengiso, ubugcisa kunye nokubumba, i-architecture, i-seal, ilebula, ukudweba imithi kunye nokukrola, umhlobiso wamatye, ukusika kwesikhumba, amashishini eengubo, njalo njalo. Kwisiseko sokufunxa itekhnoloji ephezulu yamazwe ngamazwe, sibonelela abathengi ngeyona mveliso iphambili kunye nenkonzo egqibeleleyo emva kokuthengiswa. Kwiminyaka yakutshanje, iimveliso zethu azithengiswanga kuphela e-China, kodwa nakwi-Asia-mpuma ye-Asia, kuMbindi mpuma, eYurophu, eMzantsi Melika nakwezinye iiMarike zaphesheya.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Ixesha lokuposa: Dec-17-2021