Incazelo Yomkhiqizo

Umshini wokusika we-Plasma one-bilateral drive, ukusebenza okuzinzile, ukucushwa okuhle nokusebenza kahle okuphezulu, ungasetshenziselwa amapuleti ensimbi amakhulu, aphakathi nendawo amancane adonsa amapheshana ngaphansi kwe-carbon steel ehlukahlukene, insimbi ye-manganese nezinye izinto zensimbi.Ingacushwa ngamathoshi amaningi wokudonsa ngokwezidingo zomsebenzisi, futhi ingalungiswa ngohlelo lwethoshi olumise okwe-CNC ngokwesidingo, ngohlelo lokulungiswa kobude obuzenzakalelayo be-capacitive capacitive.

Izici zomkhiqizo

Ukuthuthukiswa komshini wokusika i-Plasma kuze kube manje, igesi esebenzayo ingasetshenziswa (igesi esebenzayo i-plasma arc conductive medium, kodwa futhi nomzimba ophethe ukushisa, kodwa futhi ukukhipha insimbi encibilikisiwe ekusikeni) ezicini zokusika ze-plasma. i-arc nekhwalithi yokusika, isivinini sinomthelela omkhulu.Amagesi asebenzayo e-plasma arc asetshenziswa kakhulu yi-argon, i-hydrogen, i-nitrogen, i-oxygen, umoya, umhwamuko wamanzi nezingxube ezithile zegesi.

Imishini yokusika i-Plasma isetshenziswa kabanzi ezimbonini ezahlukahlukene ezifana nezimoto, izitimela, imikhumbi yokucindezela, imishini yamakhemikhali, imboni yenuzi, imishini ejwayelekile, imishini yobunjiniyela nezakhiwo zensimbi!Indlela ephephile, elula, ephumelelayo, eguquguqukayo futhi enobungani bemvelo yokucubungula okushisayo (ukusika, ukushisela, ukubrasa, ukucisha, ukufutha, njll.) yezinsimbi ezisuka ku-0.3 mm ukujiya ngokuthola i-plasma emhwamukeni wamanzi ingeyokuqala yohlobo lwayo emlandweni. wemboni yensimbi.

Isimiso sokusebenza

I-Plasma iyigesi eshiselwa ekushiseni okuphezulu kakhulu futhi i-ionized kakhulu, idlulisela amandla e-arc ku-workpiece, ukushisa okuphezulu kubangela ukuba ucezu lokusebenza luncibilike futhi luqhunyiswe, lwakha isimo sokusebenza se-plasma arc cutting.Umoya ocindezelwe ungena kuthoshi futhi usakazwa yigumbi legesi ngezindlela ezimbili, okungukuthi ukwenza igesi ye-plasma kanye negesi elisizayo.I-arc ye-plasma isebenza ngokuncibilikisa insimbi, kuyilapho igesi elisizayo lipholisa izingxenye zethoshi futhi liphephetha insimbi encibilikisiwe.Ukunikezwa kwamandla okusika kuqukethe izingxenye ezimbili: isifunda esikhulu kanye nesifunda sokulawula.Isimiso sikagesi: isifunda esiyinhloko siqukethe i-contactor, i-transformer yamandla ezigaba ezintathu ezinokumelana nokuvuza okuphezulu, i-rectifier ye-bridge yesigaba ezintathu, i-high-frequency arc-directing coil kanye nezingxenye zokuvikela.Ukumelana nokuvuza okuphezulu kuholela esicini esiwumqansa sangaphandle samandla kagesi.Isifunda sokulawula siqedwa ngokushintsha inkinobho ye-push-ithoshi kuyo yonke inqubo yokusika: ukungena komoya ngaphambili - ukunikezwa kwamandla wesifunda esikhulu - ukuqaliswa kwe-arc ephezulu-frequency - inqubo yokusika - ukuphumula kwe-arc - stop.Ukunikezwa kwamandla kumjikelezo oyinhloko kulawulwa yi-contactor;ukugeleza kwegesi kulawulwa yi-valve ye-solenoid;isifunda sokulawula silawula i-oscillator ephezulu yokushisa i-arc futhi imise imvamisa ephezulu ngemuva kokusungulwa kwe-arc.

Imingcele yomkhiqizo

| Imodeli | 1530 63APlasma cutting machine (ukucushwa okuphezulu) |

| X,Y indawo yokusebenza | 1500*3000mm |

| Z indawo yokusebenza | 150mm |

| Ubukhulu bokupakisha | 2280mm*3850mm*1850mm |

| Lathe bed | Isakhiwo sensimbi esiwugqinsi kakhulu |

| Amandla Omshini | 16kw |

| I-voltage esebenzayo | 380V isigaba sesithathu 60hz |

| Beka kabusha ukunemba | 0.02mm |

| Icubungula ukunemba | 0.1mm |

| Isivinini esikhulu sokusika | 12000mm/min |

| Imodi yokulawula Ukuphakama kwethoshi | Okuzenzakalelayo |

| Ukusika ukujiya | Ubukhulu bensimbi ye-carbon 12mm |

| Ukunikezwa kwamandla ePlasma | I-LGK63A |

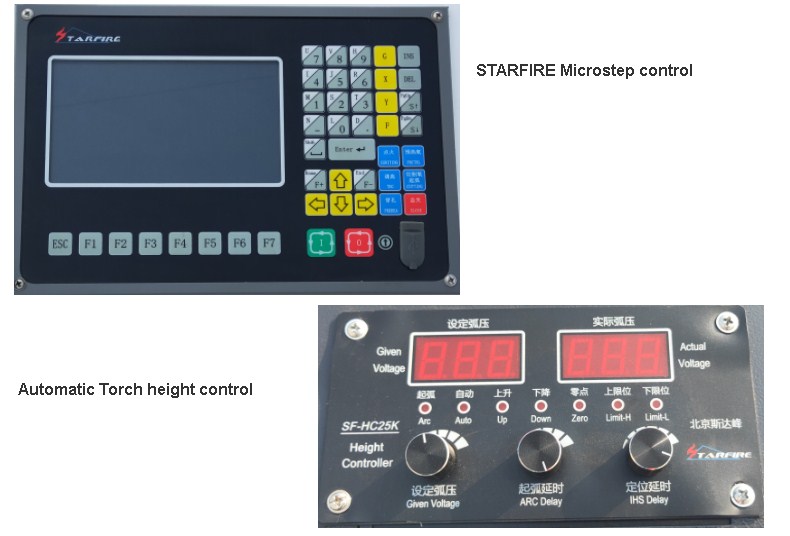

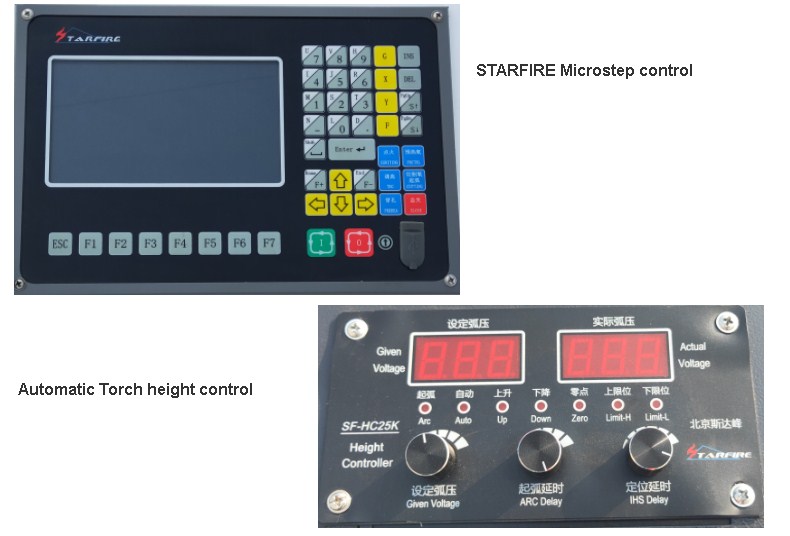

| Isistimu yokulawula | STARfire |

| Izimoto | I-stepper motor |

| Isofthiwe | I-Starcam |

| Isisindo | 1600KG |

| I-Plasma Air Pressure | Ubukhulu.0.8Mpa |

| Izinga Lokushisa Lokusebenza | -10°C-60°C.Umswakama Ohlobene, 0-95%. |

| I-LCD Display Dimension | 7 amayintshi |

Imininingwane yomkhiqizo

Izinto Ezisebenzayo

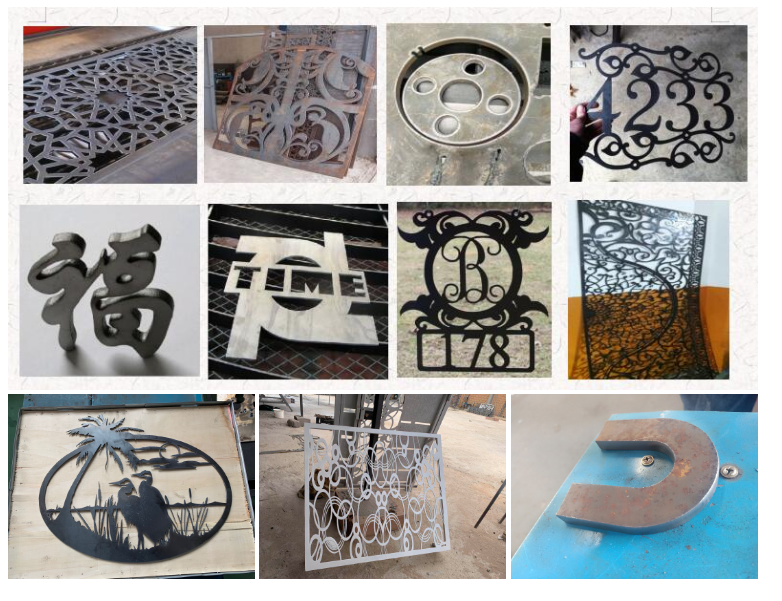

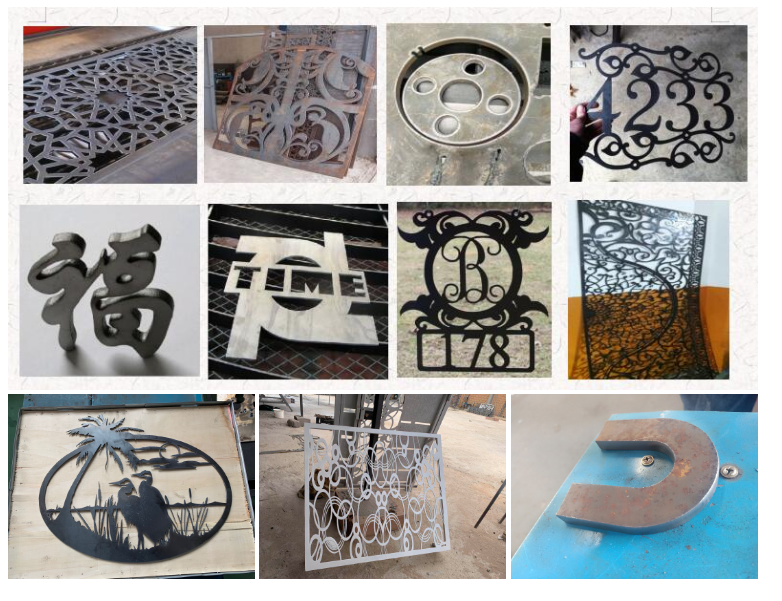

To umshini wokusika i-plasma1530, yasika zonke izinsimbi, okuhlanganisa kodwa okungagcini nje nge-aluminium sheet, iron sheet, galvanized (steel) sheet, mild steel, titanium sheet, stainless steel, iron njll.

Imboni esebenzayo

Imboni yokukhangisa: Izimpawu zokukhangisa, ukumaka uphawu, imikhiqizo yokuhlobisa, ukukhiqizwa kokukhangisa kanye nezinhlobonhlobo zezinto zensimbi.

Imboni Yesikhunta: Ukuqopha isikhunta sensimbi esenziwe ngethusi, i-aluminium, insimbi nokunye.

Imboni yensimbi: Ngensimbi, i-Carbon Steel, i-Stainless steel, i-alloy steel, i-spring steel, ipuleti lethusi, ipuleti le-aluminium, igolide, isiliva, i-Titanium nezinye ipuleti lensimbi neshubhu.

Izithombe zomshini

Izithombe zefekthri nezokuthutha