Ziningi izindlela zokushisela insimbi, njenge-argon arc yendabukoukushisela, i-welding kagesi neminye imishini yokushisela evamile.

Eminyakeni yamuva, laser cutting kanyelaser weldingbangene emkhakheni wokucubungula nokubunjwa kwensimbi. Umshini wokushisela we-laser ophethwe ngesandla unezinzuzo ezisobala ekusebenzeni kahle nasekusebenziseni kalula, futhi ukhiqize ngokushesha "umphumela we-metal welding iteration", ongacishe umiselele i-argon arc welding, i-welding kagesi nezinye izinqubo. Ingasetshenziswa emnyango nasefasiteleni hardware, imisebenzi yezandla, ukukhanyisa, metal ukukhangisa, hardware ekhishini kanye yokugezela, tableware, ekhishini zikagesi, imishini yezolimo kanye namahlathi, imishini yezokwelapha, ezemidlalo imfanelo imishini kanye nezinye industries.Metal laser cutting, ukugoba kanye Welding okudidiyelwe. uhlelo lokucubungula.

Yiziphi izinzuzo zemishini yokushisela i-laser ephathwayo?

Umshini wokushisela we-laser ophethwe ngesandla uthuthukisa iziphambeko zokushisela ezifana ne-undercut, ukungena okungaphelele, i-porosity eminyene kanye nemifantu kunqubo yokushisela yendabuko. I-weld seam ngemva kokushisela ibushelelezi futhi inhle, okunciphisa inqubo yokupholisha elandelayo futhi konga isikhathi nezindleko. Futhi kukhona okusebenzisekayo okumbalwa, impilo ende, futhi ingaba bucayi futhi ifanele izindawo ezahlukahlukene.

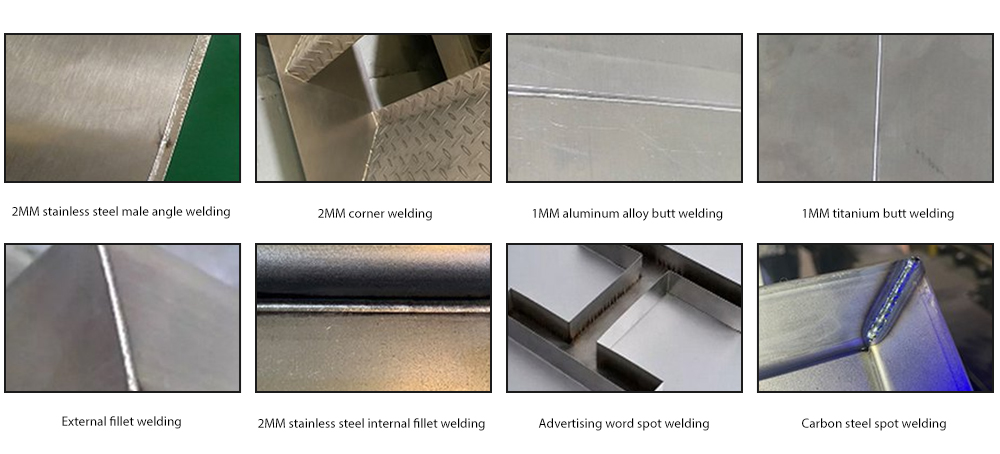

1. Mane usethe amapharamitha futhi ungaqala ngokushesha. Ngemva kokushintsha i-nozzle, akunandaba ukuthi i-welding flat, i-engeli yangaphakathi, i-engeli yangaphandle, i-overlap welding, njll.

2. I-laser beam iyisilinganiso, ikhwalithi ephezulu, iyaqhubeka futhi izinzile, futhi ukubonakaliswa kuyisilinganiso. Umphumela wokushisela uyafana kungakhathaliseki ukuthi usaqala noma ujwayelekile, futhi ngeke kube nezinkinga ezifana nama-pores, ubuhlalu be-weld, ukungena kwe-weld, kanye ne-workpiece deformation.

3. Ngezinto zensimbi ezifana nensimbi engagqwali, ishidi likathayela, ipuleti elibandayo, njll., ngokuyisisekelo ingaqeda ukushisela okushesha ngesikhathi esisodwa, okushesha izikhathi eziningana kunezinye izindlela zokushisela.

Ukwethulwa kwe-Handheld Laser Welding Machine

I-laser welder ephathwa ngesandla iyisisetshenziswa esisha esithatha indawo yokushisela okujwayelekile. Inejubane lokushisela elisheshayo kunelokushisela ngokwesiko.

1. Elula, kulula ukuyifunda, ebucayi futhi elula. Ukwamukela isakhiwo esihlanganisiwe, opharetha akafuni kakhulu, ukuqeqeshwa okulula kungasetshenziswa, ukusebenza okulula, okusheshayo ukuqalisa; welding multi-dimensional, ebucayi futhi elula;

2. Izindleko eziphansi zokutshala izimali kanye nezindleko zokuyilungisa. I-laser welding ebanjwa ngesandla, asikho isidingo setafula lokushisela ngokunemba, izinto ezisetshenziswayo ezincane, izindleko eziphansi zokuphakelwa kwemishini kanye nokugcinwa kwayo, kanye nokusebenza kwezindleko eziphezulu;

3. Yonga abasebenzi. I-laser welding ebanjwa ngesandla iyashesha, ishesha kunokushisela okujwayelekile, futhi i-weld seam ngemva kokushisela ibushelelezi futhi inhle, kunciphisa inqubo yokugaya yokulandelela, ukonga isikhathi nezindleko;

4. Ikhwalithi enhle. I-laser welding workpiece ayinakho ukuguqulwa, asikho isibazi sokushisela, futhi ukushisela kunamandla;

5. Ukuvikela ukuphepha. Inomsebenzi wokuvikela ukuphepha kokuxhumana ukuvimbela ukukhanya ukuthi kungakhiphi ngephutha, nokuqinisekisa ukuthi ukukhanya kushiselwe ngemva kokuxhumana nensimbi. Ifakwe izibuko zokuzivikela ze-laser, ezidinga ukugqokwa lapho zishiswa. Ukuqinisekisa ukuphepha.

Umshini wokushisela isibuko esiphathwayo unezinhlobo ezingafinyelela kweziyisi-6 zamabala akhanyayo, ongaqedela ukushisela i-fillet, ukushisela okuqondile, ukushisela okuthungayo, nokuthunga ukushisela, futhi kuphendule izinhlobo ezihlukahlukene zezicelo zohlelo.

Izindawo zokufaka izicelo eziyinhloko

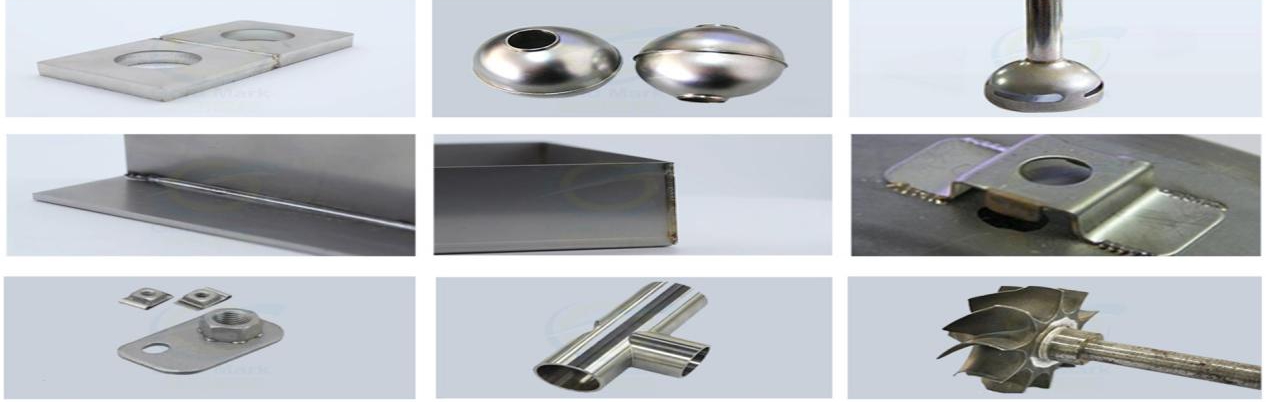

Ukucubungula insimbi yamashidi emakhishini nasezindlini zokugezela, amakheshi, amashalofu, ihardware, izinto zokwakha, iminyango namafasitela, izembozo zemigodi, izixhumi zokungcola, imisebenzi yezandla nezinye izimboni, kanye nokushisela nge-laser kwezimpahla zamashidi namapayipi ezimbonini ezifana nemishini yobunjiniyela kanye nokuhlanganisa imikhumbi.

Idatha eshiselayo

I-Carbon steel, insimbi engagqwali, i-aluminium alloy, ithusi, ithusi, ipuleti lokuqoqa, ipuleti lika-galvanized, ipuleti lensimbi ye-silicon, ipuleti le-electrolytic, i-titanium alloy, ingxubevange ye-manganese nezinye izinto zensimbi.

I-Jinan Gold Mark CNC Machinery Co., Ltd.iyimboni yobuchwepheshe obuphezulu obukhethekile ekucwaningeni, ekukhiqizeni nasekudayiseni imishini kanje: Umqophi we-Laser, umshini wokumaka we-Fiber Laser, i-CNC Router. Imikhiqizo isetshenziswe kabanzi ebhodini lesikhangiso, ubuciko kanye nokubunjwa, izakhiwo, uphawu, ilebula, ukuqopha izinkuni nokuqopha, umhlobiso wamatshe, ukusika isikhumba, izimboni zezingubo, njalonjalo. Ngesisekelo sokumunca ubuchwepheshe obuphambili bamazwe ngamazwe, sinikeza amaklayenti ukukhiqiza okuthuthuke kakhulu kanye nesevisi ephelele ngemva kokuthengisa. Eminyakeni yamuva nje, imikhiqizo yethu ayizange ithengiswe e-China kuphela, kodwa futhi kuze kufike eNingizimu-mpumalanga ye-Asia, eMpumalanga Ephakathi, eYurophu, eNingizimu Melika nakwezinye izimakethe zaphesheya kwezilwandle.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Isikhathi sokuthumela: Feb-21-2022