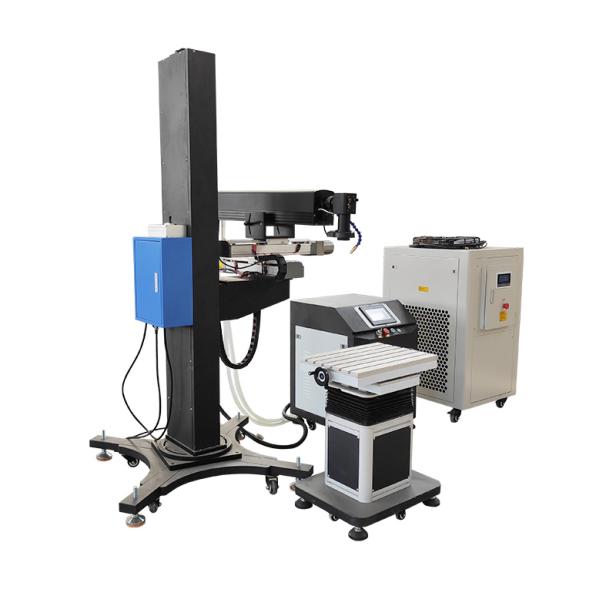

Umshini wokushisela we-laserisetshenziswa emkhakheni we-welding, futhi ingenye yezici ezibalulekile zokusetshenziswa kobuchwepheshe bokucubungula impahla ye-laser. Ngokwemodi yayo yokusebenza, ingahlukaniswa ngomshini wokushisela isikhunta se-laser, umshini wokushisela we-laser othomathikhi, nomshini wokushisela indawo we-laser, umshini wokushisela we-fiber laser, njll. Yiziphi izinzuzo zomshini wokushisela we-laser?

- Ø Izinzuzo

1. Ngemuva kokugxila kwe-laser, ukuminyana kwamandla kuphezulu. Ngemuva kokuthi i-laser yemodi ye-oda eliphansi yamandla aphezulu isigxilile, ububanzi bendawo okugxilwe kuyo buncane kakhulu.

2. Ijubane le-laser welding liyashesha, ukujula kukhulu, futhi ukuguqulwa kuncane. Ngenxa yobuningi bamandla amakhulu, kwakhiwa izimbobo ezincane ezintweni zensimbi ngesikhathilaser Welding inqubo, futhi amandla e-laser adluliselwa engxenyeni ejulile yomsebenzi ngokusebenzisa izimbobo ezincane, futhi kukhona ukusabalalisa okuncane kwe-lateral. Ijubane liyashesha, futhi indawo yokushisela ngesikhathi seyunithi inkulu.

3. I-welding deep-to-width ratio inkulu, amandla athile amancane, indawo ethintekile ukushisa incane, futhi i-welding deformation incane. Ifaneleka ngokukhethekile ukushiselwa kwezingxenye ezinembayo nezizwela ukushisa, ezingagwema ukucubungula kwamathambo kwangemuva kwe-weld kanye nesesibili.

4. Ingafakwa ekamelweni lokushisa noma ngaphansi kwezimo ezikhethekile, futhi imishini yokushisela ilula.

5. Ingakwazi ukushisela izinto eziphikisayo, njenge-titanium, i-quartz, njll., futhi ingashisela izinto ezihlukahlukene, njengethusi ne-tantalum, izinsimbi ezimbili ezinezakhiwo ezihluke ngokuphelele zihlanganiswe ndawonye, futhi umphumela muhle.

6. I-Micro-welding ingenziwa. Ngemuva kokuthi i-laser beam igxilile, indawo encane ingatholakala, futhi ingabekwa kahle, engasetshenziswa ekushiseleni umhlangano wezingxenye ezincane nezincane ekukhiqizeni okuzenzakalelayo okukhulu. Akukhona nje kuphela ukusebenza kahle kokukhiqiza okuthuthukisiwe kakhulu, kodwa futhi indawo ethintekile ukushisa incane futhi i-solder joint ayinakho ukungcola, okuthuthukisa kakhulu izinga lokushisela.

7. Ingakwazi ukushisela izingxenye okunzima ukufinyelela kuzo futhi isebenzise i-welding yebanga elide engathinteki, ekwazi ukuguquguquka okukhulu.

8. Ngokuvamile, ayikho insimbi yokugcwalisa eyengezwe. Uma ivikelwe ngokugcwele ngegesi ye-inert, i-weld ayinakho ukungcoliswa komoya

9. Uhlelo lwe-welding luguquguquka kakhulu futhi kulula ukulwenza.

10.Umshini wokushisela we-laserI-laser welding ifana ne-electron beam welding ezicini eziningi, futhi ikhwalithi yayo yokushisela ingaphansi kancane kune-electron beam welding, kodwa i-electron beam ingadluliselwa kuphela ku-vacuum, ngakho-ke ukushisela kungenziwa kuphela ku-vacuum, futhi ubuchwepheshe be-laser welding bungasebenza. endaweni ebanzi yezindawo zokusebenza.

I-Jinan Gold Mark CNC Machinery Co., Ltd.iyimboni yobuchwepheshe obuphezulu egxile ekucwaningeni, ekukhiqizeni nasekudayiseni le mishini kanje: Umqophi we-Laser, umshini wokumaka we-Fiber Laser, i-CNC Router. Imikhiqizo isetshenziswe kabanzi ebhodini lesikhangiso, ubuciko kanye nokubunjwa, izakhiwo, uphawu, ilebula, ukuqopha izinkuni nokuqopha, umhlobiso wamatshe, ukusika isikhumba, izimboni zezingubo, njalonjalo. Ngesisekelo sokumunca ubuchwepheshe obuphambili bamazwe ngamazwe, sinikeza amaklayenti ukukhiqiza okuthuthuke kakhulu kanye nesevisi ephelele ngemva kokuthengisa. Eminyakeni yamuva nje, imikhiqizo yethu ayizange ithengiswe e-China kuphela, kodwa futhi kuze kufike eNingizimu-mpumalanga ye-Asia, eMpumalanga Ephakathi, eYurophu, eNingizimu Melika nakwezinye izimakethe zaphesheya kwezilwandle.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Isikhathi sokuthumela: Aug-02-2022