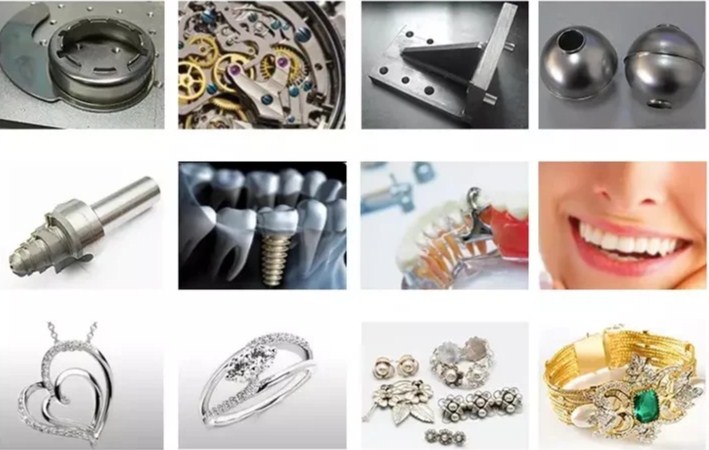

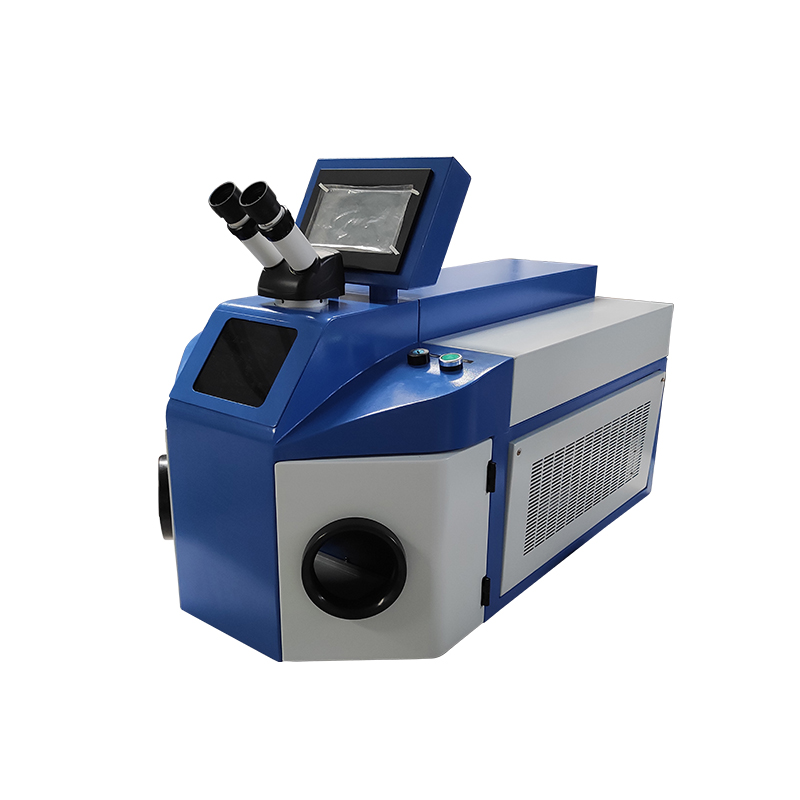

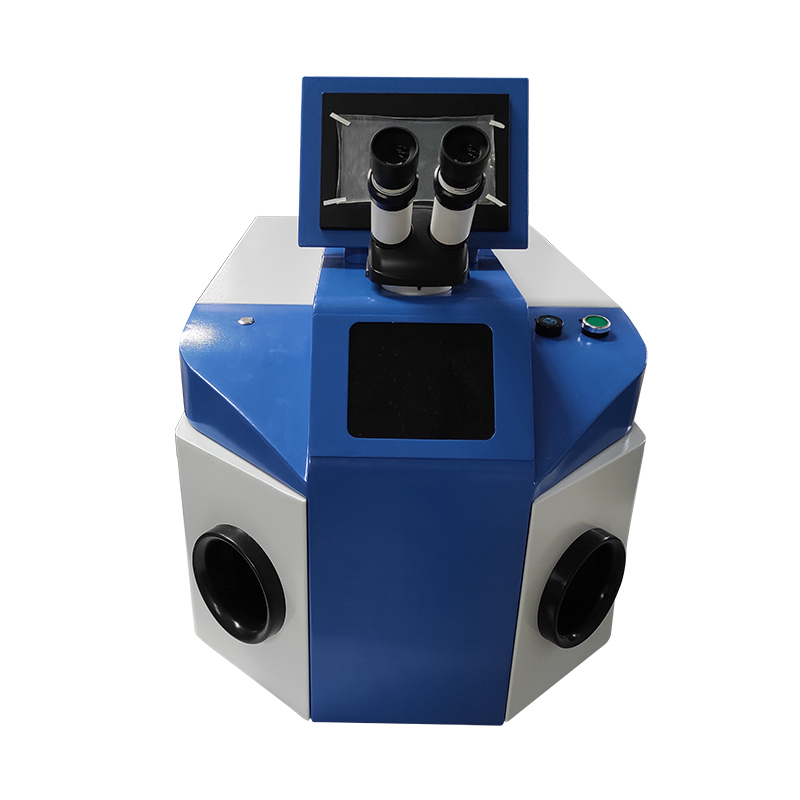

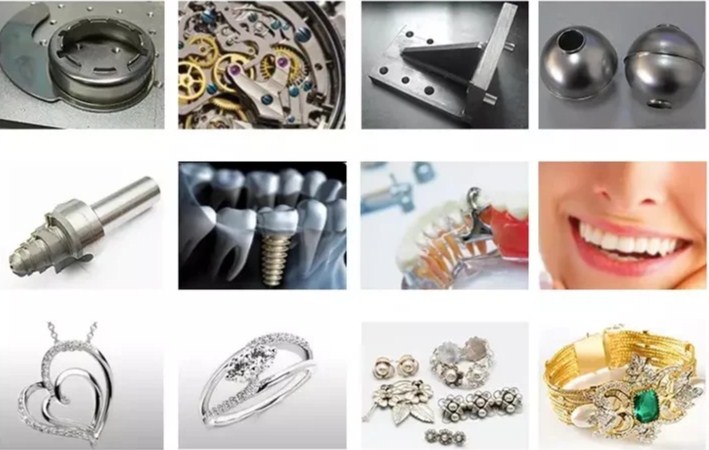

Mochini oa welding oa "desktop jewellery laser spot welding" ke sesebelisoa sa laser se hloahloa bakeng sa ho cheselletsa tšepe indastering ea mabenyane, haholo-holo e sebelisetsoang ho tlatsa masoba, trachoma le ho lokisa welding ea mabenyane a khauta le silevera.E na le melemo ea ho nepahala ho phahameng, tahlehelo e tlase le ka potlako e kholo, haholo-holo e sebelisetsoang ho tlatsa masoba, trachoma ea welding le ho lokisa welding ea mabenyane a khauta le silevera, a loketseng khauta, silevera, platinum, tšepe e sa hloekang, titanium le lisebelisoa tse ling tse boima. lisebelisoa tsa alloy, le tsona li ka sebelisoa bakeng sa ho tlatsa trachoma ea meno a maiketsetso le lisebelisoa tse nyane tse nepahetseng joalo ka tepi ea nickel ea betri, li-circuits tse kopaneng, lioache le li-watch filaments, li-tubes tsa litšoantšo, kopano ea lithunya tsa elektroniki le likarolo tse ling tsa welding.

Likarolo tsa sehlahisoa

● E na le Chaomi Laser's "voltage regulated pulse power supply" ka bo eona, e kopanang ka boholo 'me e na le matla a fetang 15% ho feta phepelo ea motlakase e tloaelehileng.E loketse haholoanyane ho cheselletsa khauta, silevera le lisebelisoa tse ling tse bonahatsang haholo.

● Karolo ea mantlha ea "laser cavity" ke sepakapaka se khanyang sa khauta, se fanang ka ts'ebetso e tsitsitseng haholoanyane le bophelo bo bolelele ba tšebeletso, ho fa basebelisi litharollo tse sebetsang hantle le tsa moruo.

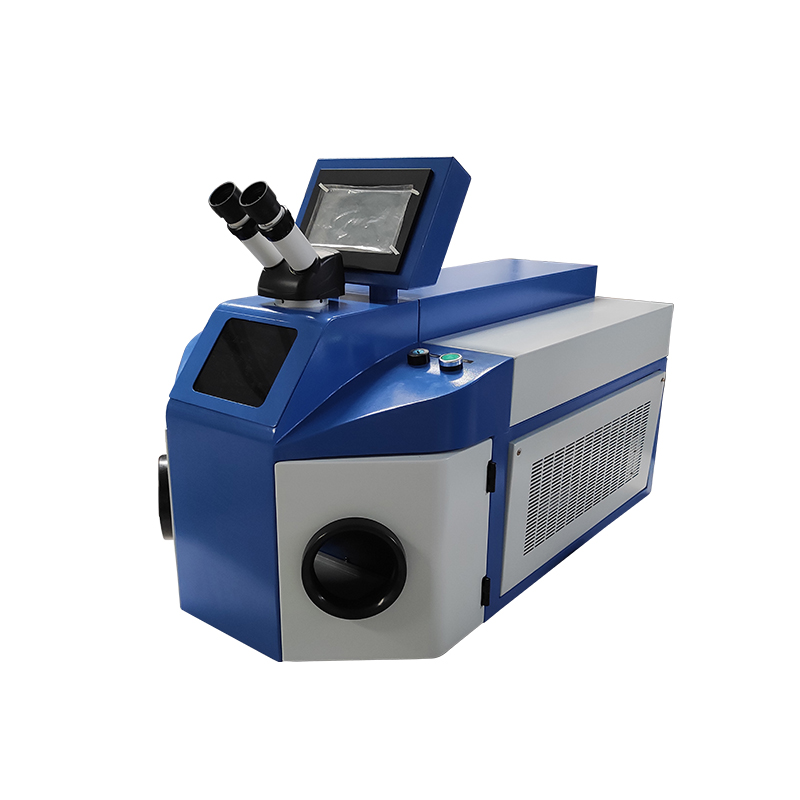

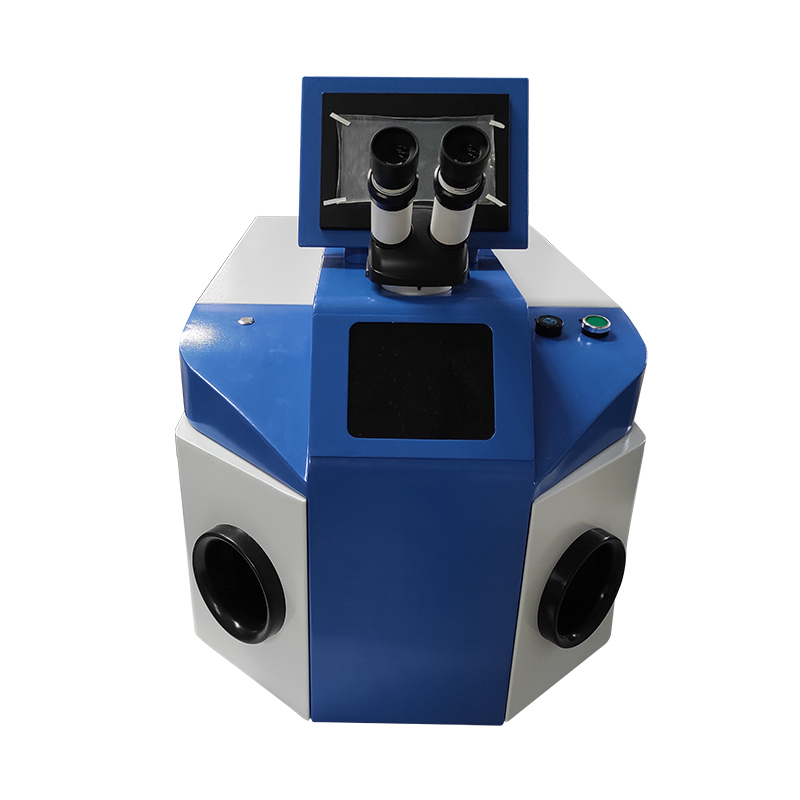

● Sebopeho sa mochine se ntlafalitsoe bakeng sa ho kopana le ho nkeha habonolo, ho etsa hore e be mochine oa 'nete oa mini-welding o sebetsang hantle haholo.

● Boleng bo phahameng ba ho tjheseletsa le seam se setle sa weld, seam sa weld se ka ba le matla a lekanang le thepa ea motheo ntle le ts'ebetso ea bobeli, ka katleho ho ntlafatsa tekanyo ea ho tšoaneleha ha sehlahisoa se felileng.

● A ka tjheseletsa thepa e refractory, haholo-holo e loketseng bakeng sa ho cheseletsa ka nepo ea likaroloana tse nyenyane le tse nyenyane le mabenyane.

● Ka mokhoa o ikhethileng, mochine o ka etsoa ho finyella litlhoko tsa bareki.

Lihlahisoa tsa lihlahisoa

| Mohlala | LM-200 Laser Welding Machine |

| Matla a Phallo | 100 WI 200 WI 300 W - ho itšetlehile ka tlhokahalo |

| Matla a leqeba le le leng | 0-100 J |

| Mofuta oa Moqapi oa Mochini | Desktop I Vertical |

| Mohloli oa Laser | ND: YAG |

| Laser Wavelength | 1064 nm |

| Lebone la pompo | Lebone la Xenon la Pulsed |

| Pulse Width | 0.1.15 ms e ka fetolehang |

| Pulse e Pheta Khafetsa | 1 - 20 Hz e ka fetoloa |

| Bophara ba sebaka sa welding | 0.2-1.5 limilimithara e ka fetolehang |

| Sistimi ea ho shebella | Microscope I CCD - e ipapisitse le tlhoko |

| Mokhoa oa ho Pholisa | Sehatsetsi sa metsi |

| Phepelo ea motlakase | Mokhahlelo o le Mong AC 220V ± 10%, 50Hz I 60HZ, 4 KW |

| Tikoloho ea ho Matha | Mocheso 5°C-28°C Mongobo 5%-70% |

Mohlala oa Show