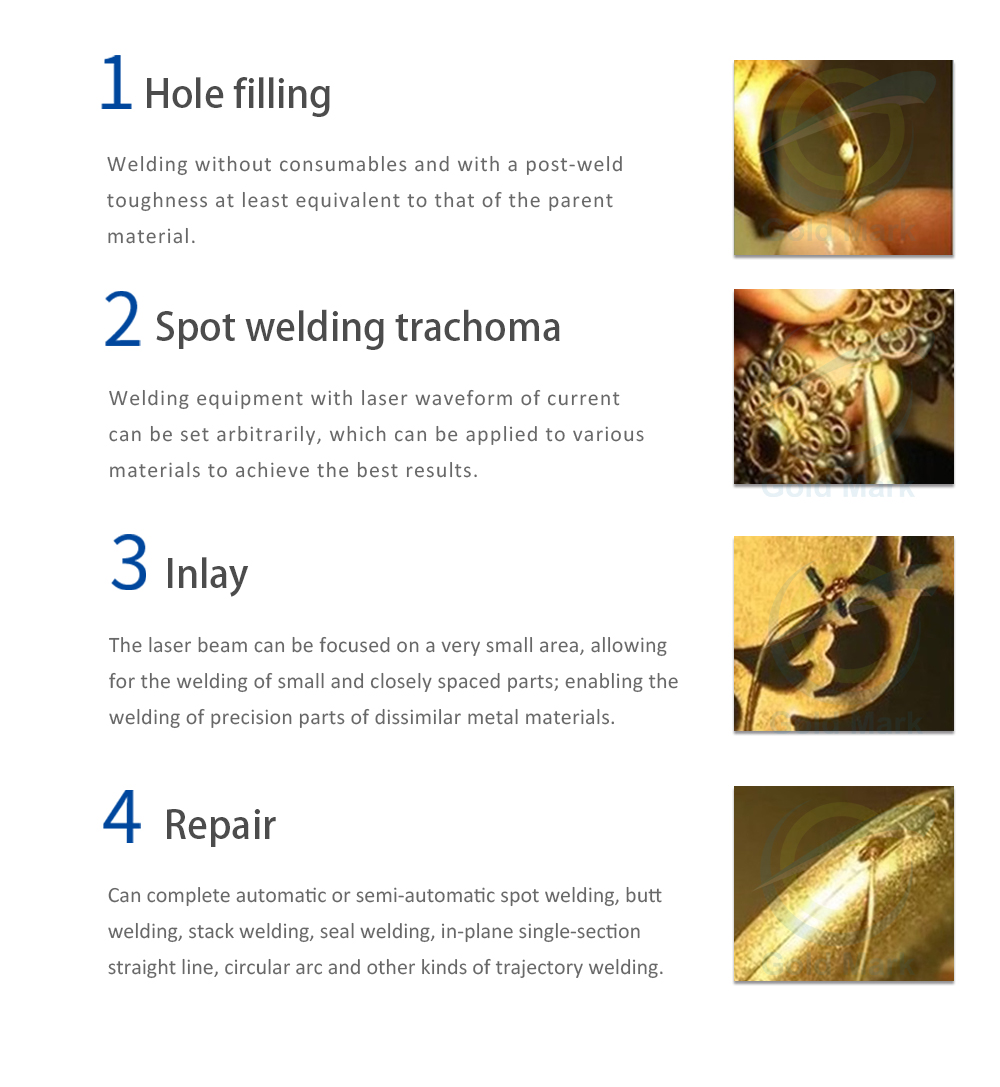

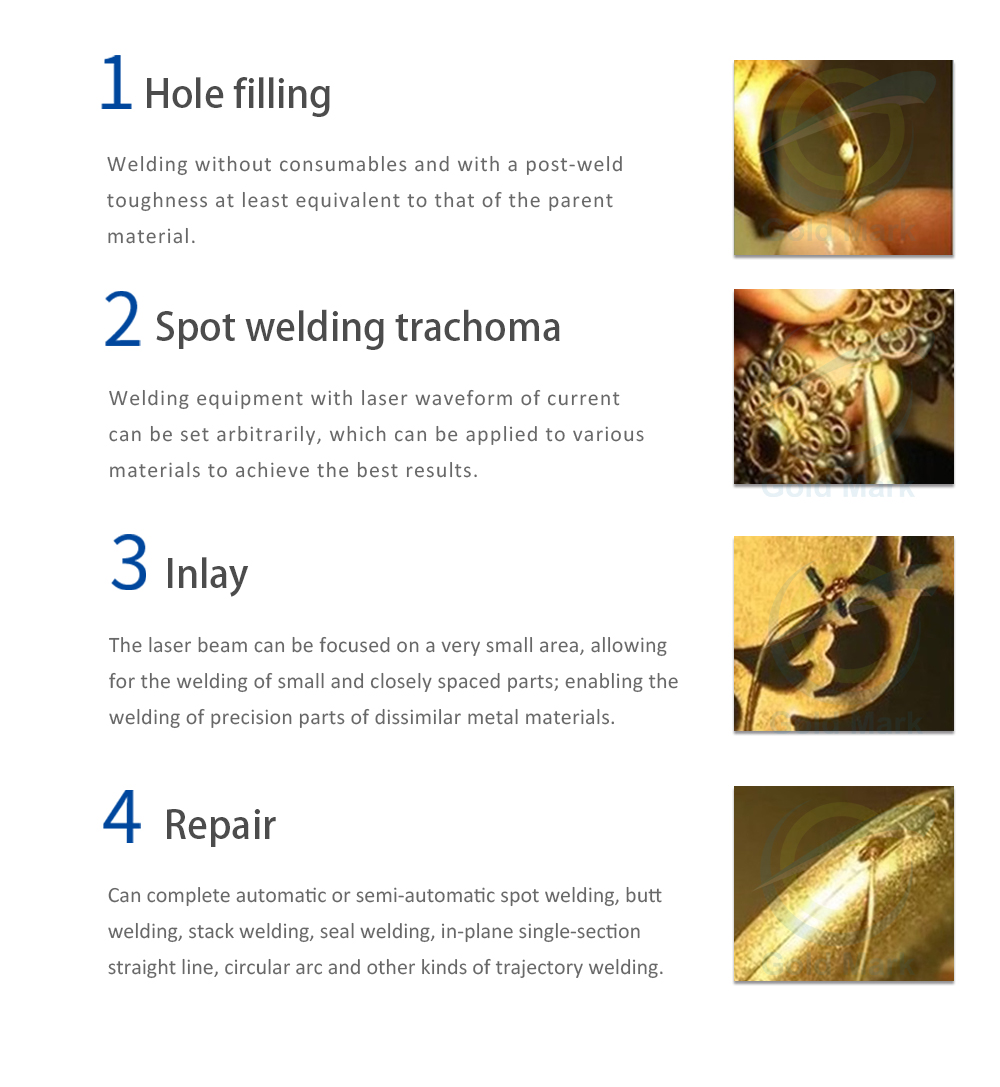

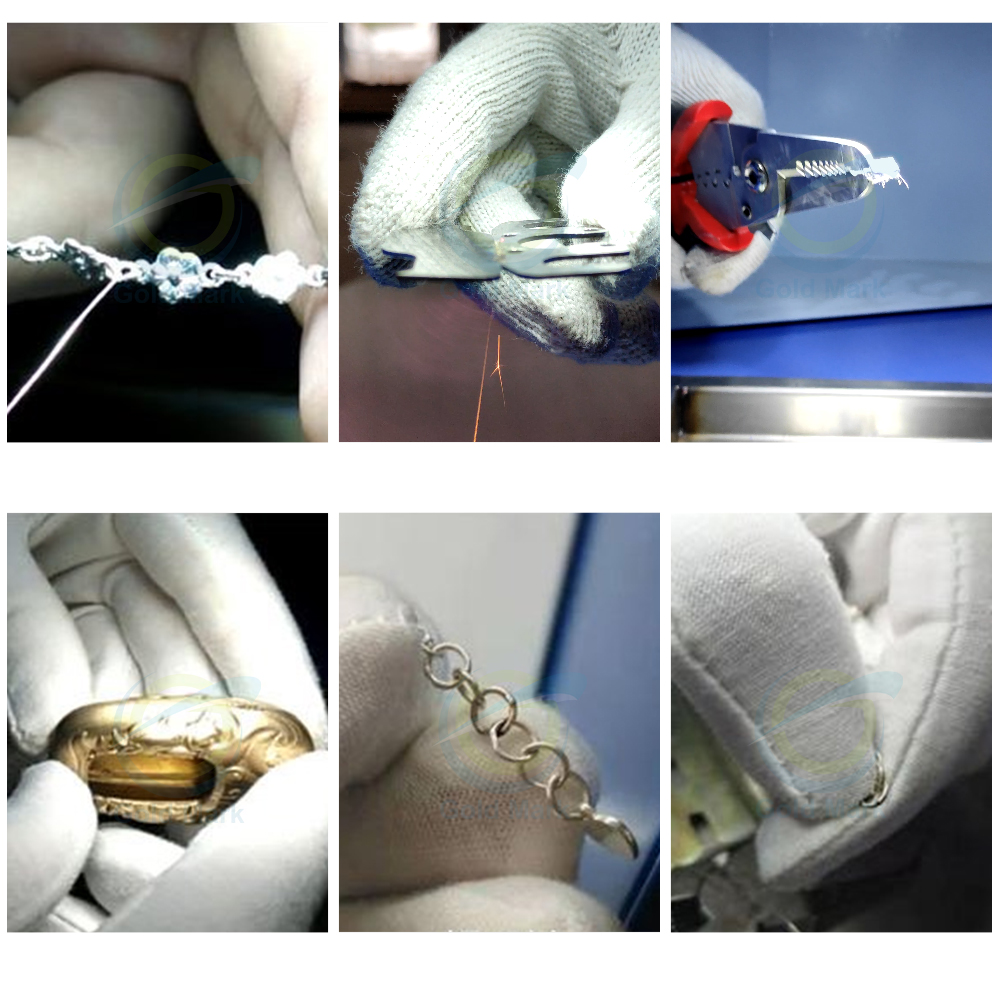

Mochini ona oa welding oa laser o sebelisoa ka ho khetheha bakeng sa mabenyane a khauta le silevera, libolo tsa kolofo, lisebelisoa tsa elektroniki ho tlatsa masoba, trachoma ea welding, welding inlay, joalo-joalo. The welding e tiile, e ntle, ha e na deformation, e bonolo ho e bala sebelisa, joalo-joalo E na le melemo ea ho potlaka ka potlako, bokhoni bo phahameng, botebo bo boholo, deformation e nyenyane, sebaka se senyenyane se anngoeng ke mocheso, joalo-joalo Boleng ba tjheseletsa bo phahame, 'me lenonyeletso le nang le welded ha le na tšilafalo le tikoloho.

E sebelisoa haholo puisanong ea liselefouno, likarolo tsa elektroniki, matla a macha, mabenyane le lisebelisoa, lihlahisoa tsa Hardware, lisebelisoa tse nepahetseng, likarolo tsa koloi, limpho tsa mesebetsi ea matsoho le liindasteri tse ling.

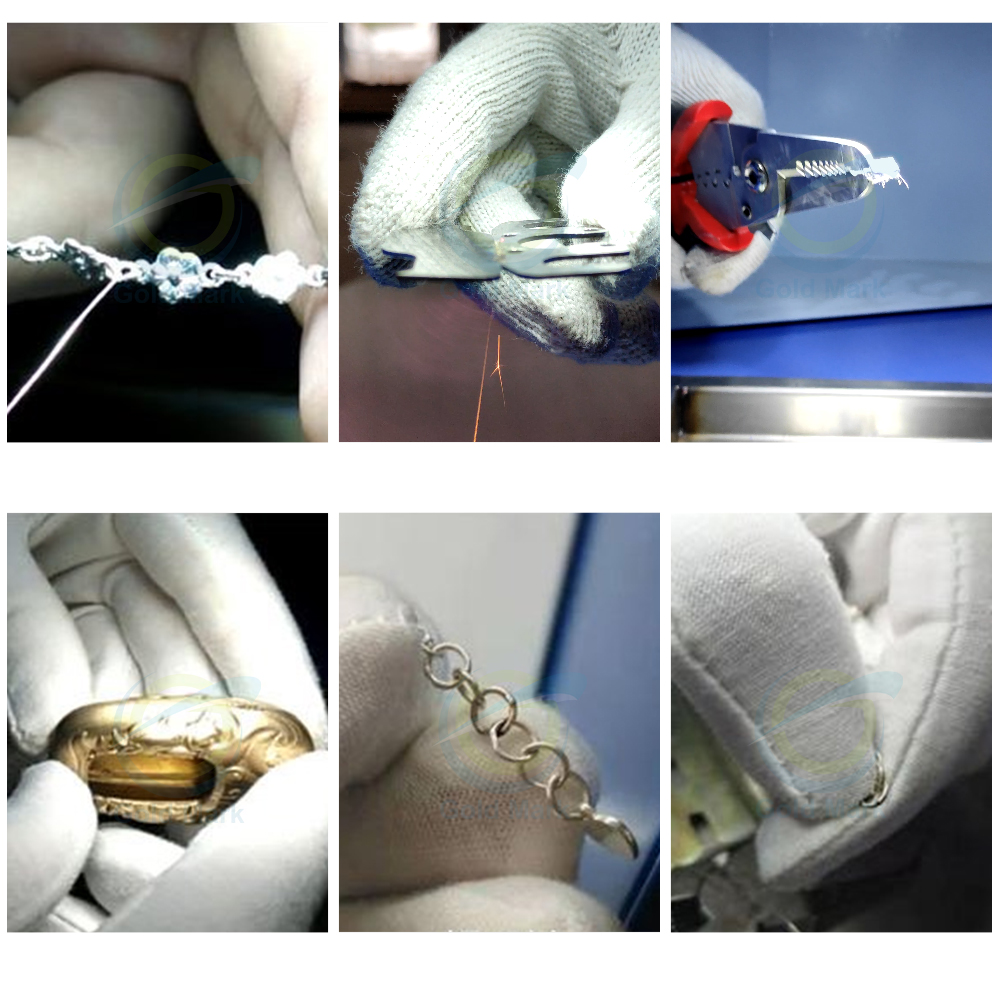

Likarolo tse nyane li sebetsa ka nepo ho kenyelletsa: mabenyane, mabenyane, hlooho ea kolofo le aluminium alloy denture, joalo-joalo, tse loketseng haholo bakeng sa masoba a patching mabenyane a khauta le silevera, trachoma ea welding, ho lokisa mela ea seam le likarolo tse inlay tsa maoto a mabenyane, jj.

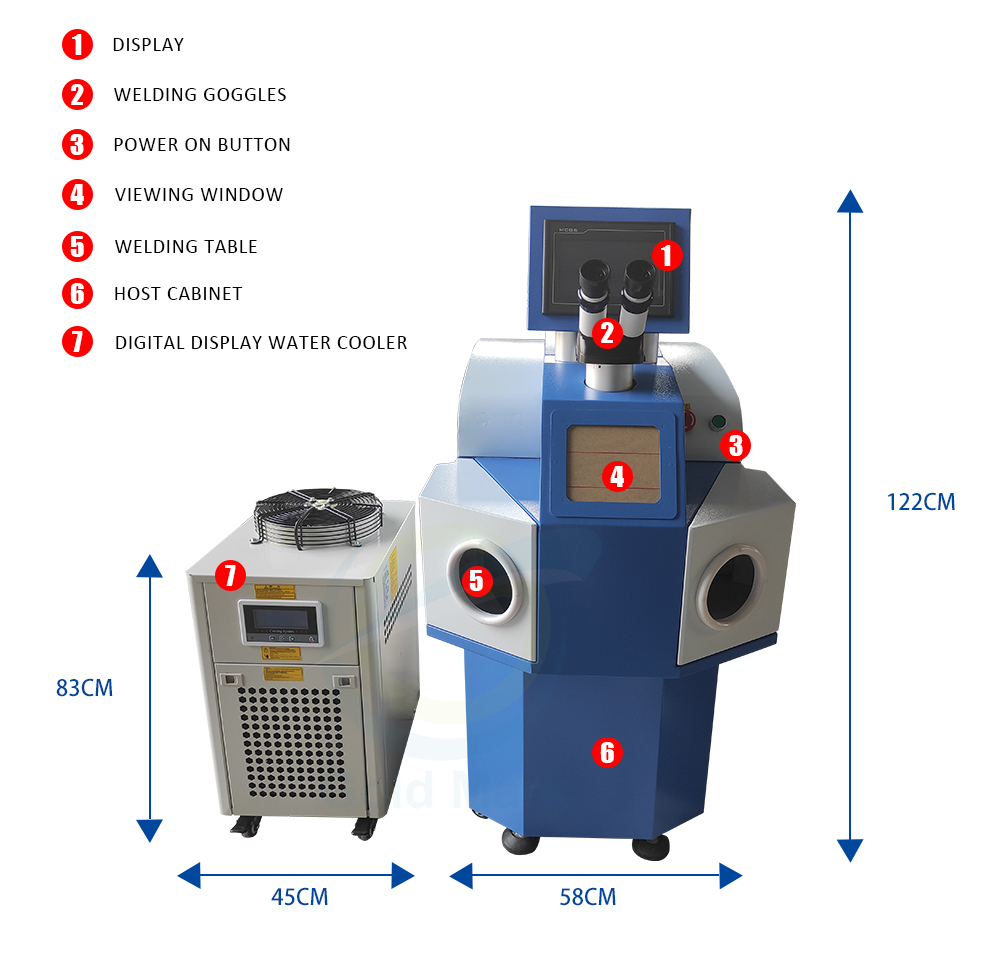

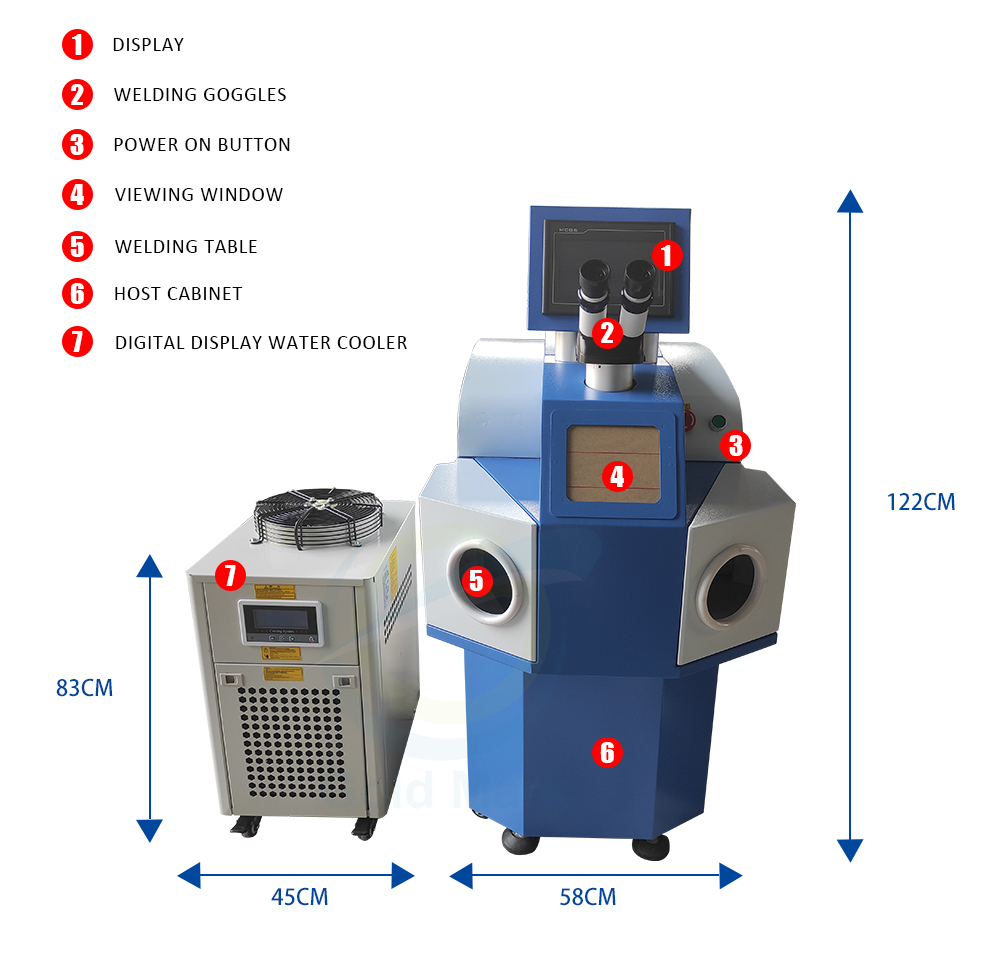

| Mohlala | LM-200 Laser Welding Machine |

| Matla a Phallo | 100 WI 200 WI 300 W - ho itšetlehile ka tlhokahalo |

| Matla a leqeba le le leng | 0-100 J |

| Mofuta oa Moqapi oa Mochini | Desktop I Vertical |

| Mohloli oa Laser | ND: YAG |

| Laser Wavelength | 1064 nm |

| Lebone la pompo | Lebone la Xenon la Pulsed |

| Pulse Width | 0.1.15 ms e ka fetolehang |

| Pulse e Pheta Khafetsa | 1 - 20 Hz e ka fetolehang |

| Bophara ba sebaka sa welding | 0.2-1.5 limilimithara e ka fetolehang |

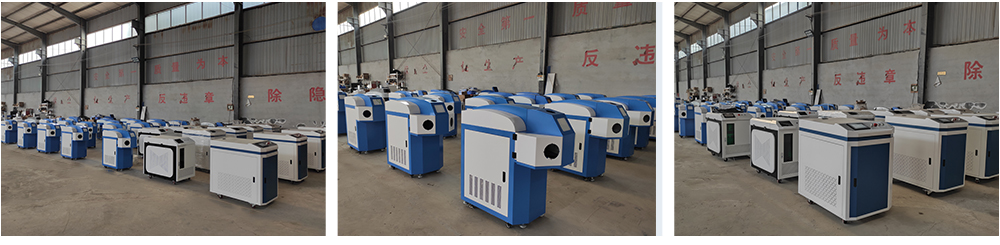

| Sistimi ea ho shebella | Microscope I CCD - e ipapisitse le tlhoko |

| Mokhoa oa ho Pholisa | Sehatsetsi sa metsi |

| Phepelo ea motlakase | Mokhahlelo o le Mong AC 220V ± 10%, 50Hz I 60HZ, 4 KW |

| Tikoloho ea ho Matha | Mocheso 5°C-28°C Mongobo 5%-70% |

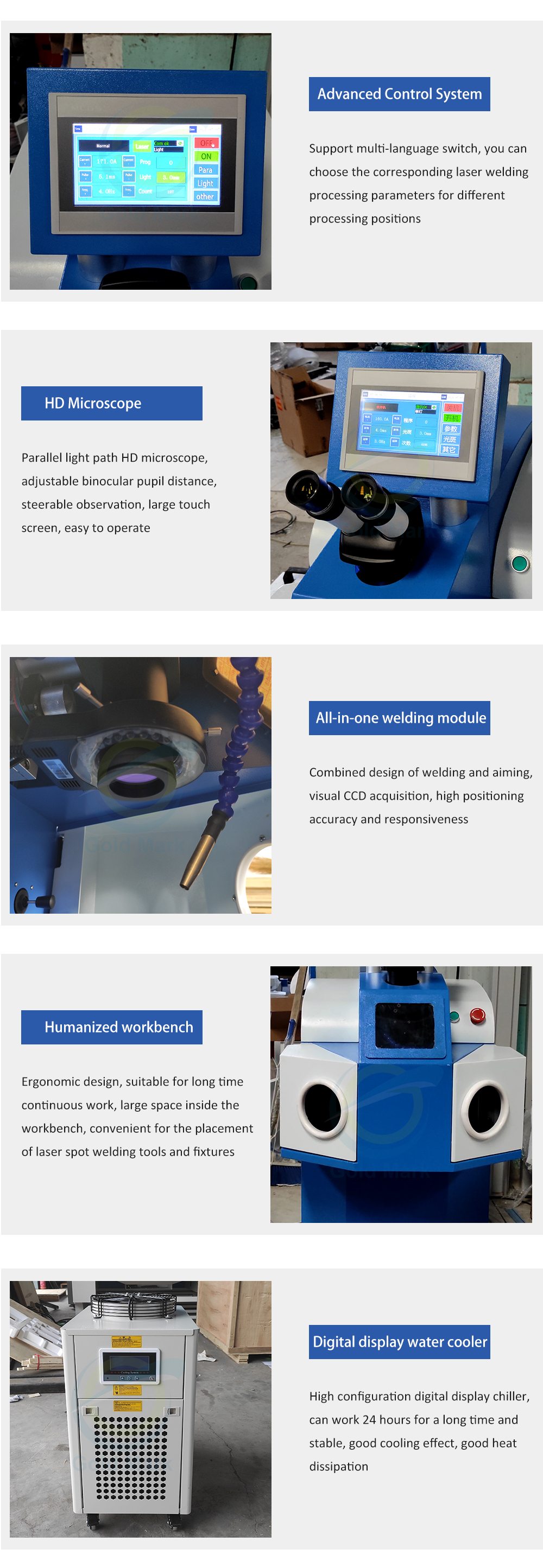

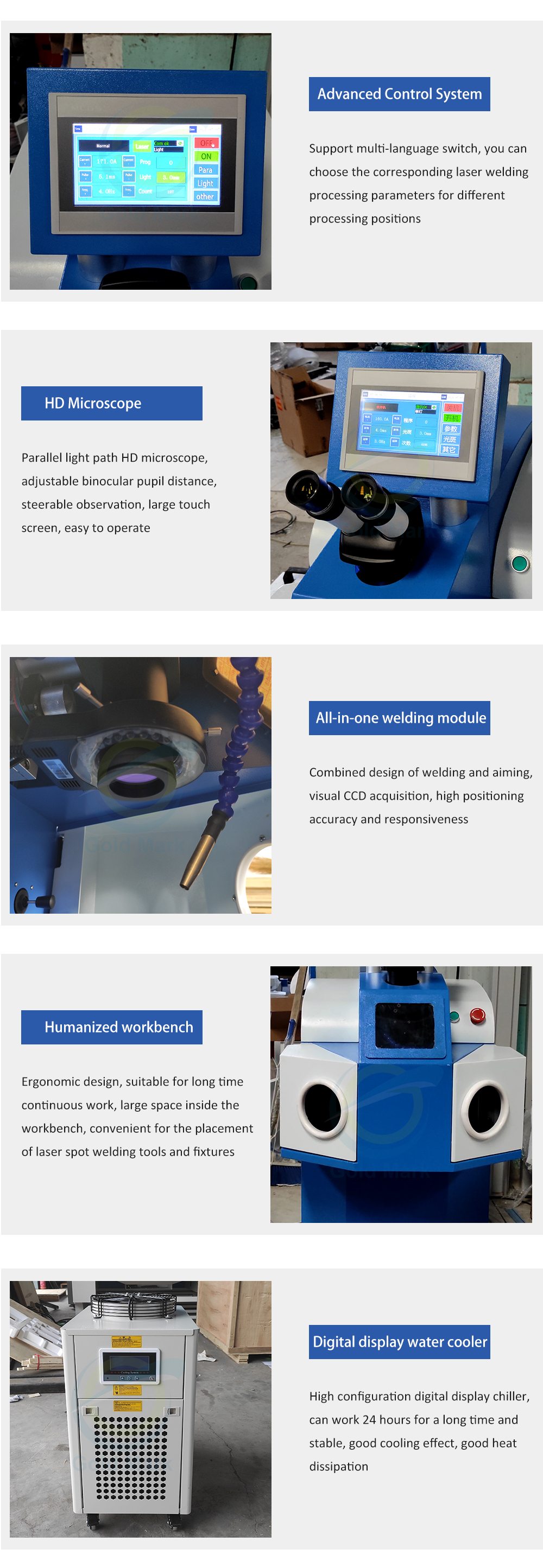

●Matla, bophara ba pulse, maqhubu, boholo ba letheba, joalo-joalo li ka fetoloa ka mefuta e mengata ho finyella liphello tse sa tšoaneng tsa welding.Liparamente li lokisoa ke lever ea taolo ka har'a sekoti se koetsoeng, se bonolo ebile se bonolo ho sebetsa.

●Ho amohela sekoti sa mabala a ceramic a tsoang kantle ho naha, a hanang kutu, a hana mocheso o phahameng, ts'ebetso e phahameng ea phetoho ea photoelectric, bophelo ba mabone (lilemo tse 8-10), bophelo ba mabone a xenon ho feta makhetlo a limilione tse 8.

●Amohela sistimi e tsoetseng pele ea lefatše ea ho etsa moriti ho qoba ts'usumetso ea mahlo nakong ea lihora tsa mosebetsi.

●Ka bokhoni ba ho sebetsa bo tsoelang pele ba lihora tse 24, mochini oohle o na le ts'ebetso e tsitsitseng mme ha o lokisoe nakong ea lihora tse 10000.

●Moralo oa batho, ergonomic, lihora tse telele tsa ho sebetsa ntle le mokhathala.