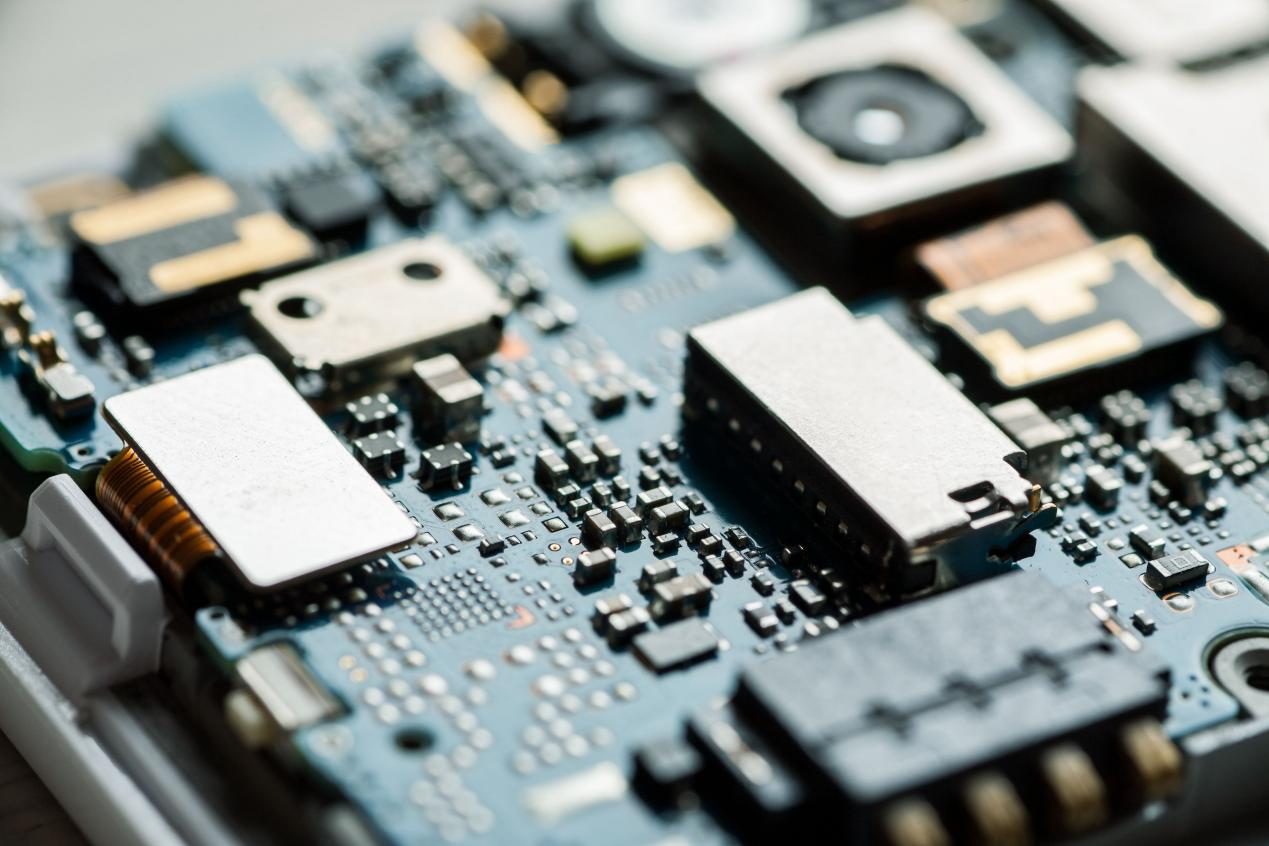

Ka ho tuma ha li-smartphones, li-TV tsa phanele le lisebelisoa tse ling, 'maraka oa lisebelisoa tsa elektroniki o bone kholo e neng e sa lebelloa. Tlhōlisano e ntseng e eketseha ka linako tsohle e entse hore indasteri ea tlhahiso ea lisebelisoa tsa elektronike e behe litlhoko tse phahameng lits'ebetsong tsa lihlahisoa. Mekhoa e tloaelehileng ea ho sebetsa e se e ntse e sa khone ho finyella litlhoko tsa mekhoa ea kajeno. Boleng bo sa tsitsang ba sehlahisoa, likarolo tse qhibilihisitsoeng, bothata ba ho etsa li-nuclei tse tloaelehileng, le litekanyetso tse fokolang tsa lihlahisoa li fetohile mathata ho bahlahisi. Ho hlaha halaser tjheseletsathekenoloji e phethile karolo e kholo ts'ebetsong ea tlhahiso ea lihlahisoa tsa elektronike tse phahameng, ka bobeli mabapi le ho ntlafatsa boleng ba lihlahisoa hammoho le ntlafatso ea boleng.

Hona joale, laser tjheseletsa ka tlhahiso ea indasteri ea elektronike e sebelisoa haholo-holo ka ho nepahala sebaka thekenoloji tjheseletsa, ho nepahalaho tjheseletsa lethebathekenoloji e na le deformation e nyane ea mocheso, karolo ea sebaka le sebaka sa taolo e nepahetseng, boleng bo phahameng ba welding, bokhoni ba ho fihlella welding ea lintho tse fapaneng, ho fihlella habonolo le melemo e meng, e ka sebelisoa ho lihlahisoa tsa elektroniki ka har'a khetla, thebe, USB sehokelo, patch conductive, joalo-joalo, empa tjheseletsa thepa e fapaneng, tlhokahalo ea ho sebelisa mekhoa e fapaneng tjheseletsa . LatelaKHAUTA LETŠOAho ithuta haholoanyane ka tse latelang.

Laser precision spot welding mokhoa oa anti-material o phahameng

Ha ho tjheseletsa thepa e bonahatsang haholo joalo ka aluminium le koporo, mefuta e fapaneng ea maqhubu a tjheseletsa e na le tšusumetso e kholo ho boleng ba tjheseletsa. Ho sebelisa laser waveform e nang le spike e ka pele ho ka phunyeletsa mokoallo o phahameng oa ho bonahatsa. Matla a phahameng a tlhōrō a hang-hang a ka fetola boemo ba tšepe ka potlako 'me a phahamisa mocheso oa eona ho fihlela a qhibiliha, kahoo a fokotsa ho bonahatsa bokaholimo ba tšepe le ho ntlafatsa tšebeliso ea matla. Ho phaella moo, kaha lisebelisoa tse kang koporo le aluminium li tsamaisa mocheso ka potlako, ponahalo ea motsoako oa solder e ka ntlafatsoa ka ho sebelisa maqhubu a theoha butle.

Ka lehlakoreng le leng, sekhahla sa ho monya ha lisebelisoa tse kang khauta, silevera, koporo le tšepe se fokotseha ka bolelele bo ntseng bo eketseha, 'me bakeng sa koporo, sekhahla sa ho monya ha koporo se haufi le 40% ha laser wavelength e le 532 nm. Papiso ea litšobotsi tsa laser ea infrared le laser e tala e bonts'a hore boholo ba letheba la infrared laser bo kholoanyane, botebo bo tebileng bo khuts'oane, 'me sekhahla sa ho monya ha koporo se tlase; boholo ba letheba la laser bo botala bo nyane, botebo bo tebileng bo bolelele, 'me sekhahla sa ho monya ha koporo se phahame. Laser ea infrared le laser pulse spot welding ea koporo, ka ho latellana, e ka fumanoa hore welding ea laser ea infrared ka mor'a boholo ba manonyeletso a sa lumellaneng, athe manonyeletso a matala a laser a boholo bo ts'oanang, botebo bo tsitsitseng, bokaholimo bo boreleli. Tšusumetso ea tjheseletsa e tsitsitse haholoanyane ka laser e tala, 'me matla a phahameng a hlokahalang e tla ba ho feta halofo ea laser ea infrared.

Laser ho nepahala letheba tjheseletsa mokhoa bakeng sa thepa tšesaane lakane tšepe

Li-lasers tsa setso tsa millisecond li na le monyetla oa ho kenella le manonyeletso a maholo ha li cheseletsa lisebelisoa tsa tšepe tse tšesaane, athe lisebelisoa tse phahameng tse fapaneng hangata li na le matheba a phatlohileng le li-welds tsa bohata ka lebaka la ho se tsitse ha tsona le ho monya ho tlase ha leseli la laser sebakeng se tiileng. E le hore u rarolle poleiti e tšesaane le mathata a phahameng a fapaneng a tšepe, ka mokhoa oa faeba laser QCW / CW ea analog le modulation ea digital, ka ho latellana, qala hang ho finyella tlhahiso ea N pulse, ka matla a fokolang ho finyella ntlha e le 'ngoe ea li-pulse tse ngata. .

Mokhoa oa ho tjheseletsa letheba ka laser bakeng sa thepa e sa tshwaneng

Laser welding ea thepa e tšesaane ea lijana tse fapaneng e ka hlaseloa habonolo ke tjheseletso ea bohata, mapetsong le matla a tlase a manonyeletso ka lebaka la phapang e kholo ea thepa ea 'mele, ho solubility ho tlase, le monyetla o moholo oa ho hlahisa metsoako ea brittle, e fokotsang haholo thepa ea mochini. hlooho ea weld. Laser ea nanosecond e nang le boleng bo phahameng ba boleng bo khethiloe ho hatella ho thehoa ha metsoako ea intermetallic ka mokhoa oa ho hlahloba ka lebelo le phahameng ka ho laola ka mokhoa o nepahetseng oa ho kenya mocheso ho lemoha lenonyeletso la lipoleiti tse tšesaane tsa tšepe tse sa tšoaneng le ho ntlafatsa sebopeho sa weld le thepa ea mechine.

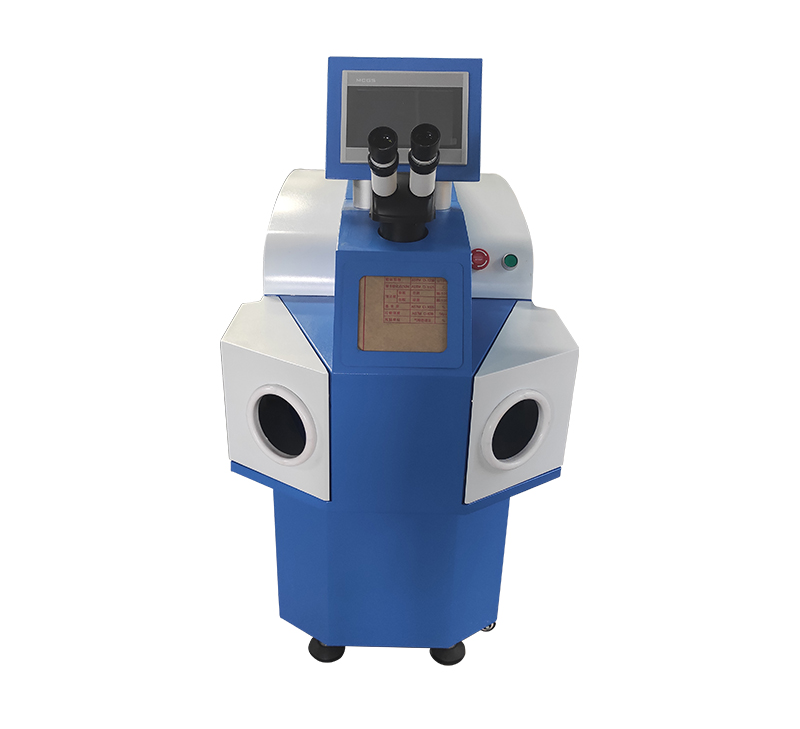

Jinan Gold Mark CNC Machinery Co., Ltd. ke indasteri ea theknoloji e phahameng e sebetsanang le ho etsa lipatlisiso, ho etsa le ho rekisa mechine ka tsela e latelang: Laser Engraver, Fiber Laser Marking Machine, CNC Router. Lihlahisoa li 'nile tsa sebelisoa haholo ka boto ea lipapatso, mesebetsi ea matsoho le ho bōpa, mehaho, tiiso, letšoao, ho betla lehong le ho betla, ho khabisa majoe, ho khaola letlalo, liindasteri tsa liaparo, joalo-joalo. Motheong oa ho monya thekenoloji e tsoetseng pele ea machabeng, re fa bareki tlhahiso e tsoetseng pele ka ho fetisisa le ts'ebeletso e phethahetseng ea kamora thekiso. Lilemong tsa morao tjena, lihlahisoa tsa rona ha li rekisoe Chaena feela, empa hape ho ea fihla Asia Boroa-bochabela, Bochabela bo Hare, Europe, Amerika Boroa le Limmaraka tse ling tsa mose ho maoatle.

Email: cathy@goldmarklaser.com

WeCha/WhatsApp: +8615589979166

Nako ea poso: Aug-27-2021