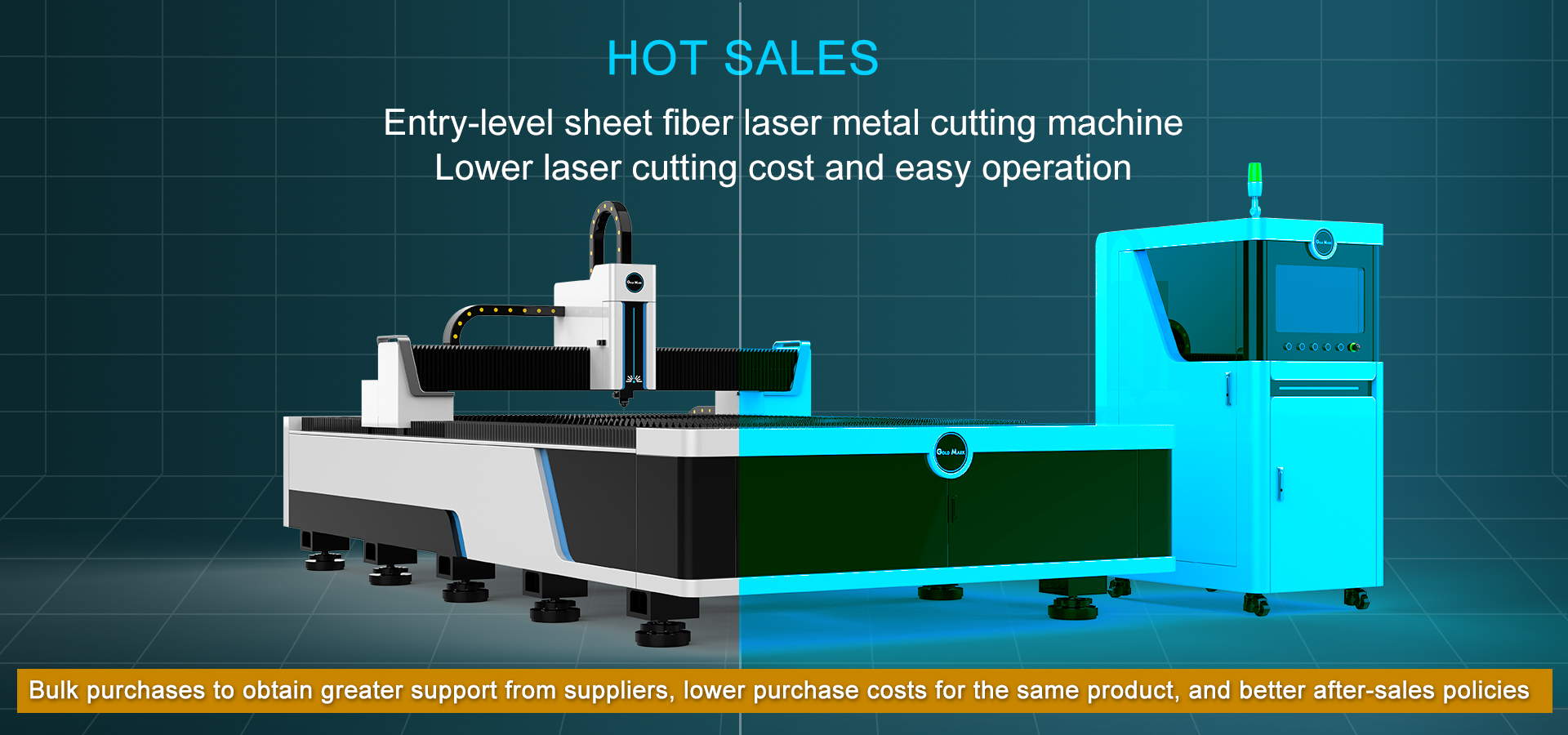

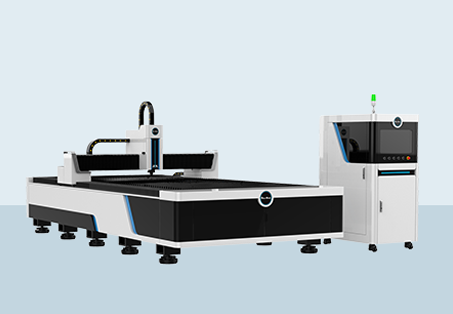

Isibonisi Sefekthri

Ukuhlukaniswa okuhlakaniphile komshini wokusika

Ngaphandle kokusebenza mathupha, ingagxila ngokuzenzakalelayo

-

Ngaphandle Kokugxila Manuwali

Isofthiwe ilungisa ngokuzenzakalelayo ilensi yokugxila ukuze ibone ukubhoboza okuzenzakalelayo nokusika amapuleti anogqinsi oluhlukene. Isivinini sokuzilungisa ngokuzenzakalelayo i-focus lens izikhathi eziyishumi zokulungiswa mathupha.

-

Ibanga Lokulungisa Elikhulu

Ibanga lokulungisa -10 mm~ +10mm, ukunemba okungu-0.01mm, lifaneleka ku-0 ~ 20mm izinhlobo ezahlukene zamapuleti.

-

Impilo Emide Yenkonzo

Ilensi ye-Collimator kanye nelensi yokugxila kokubili kunosinki wokushisa opholisa amanzi okwehlisa izinga lokushisa lekhanda elisikayo ukuze kuthuthukiswe impilo yekhanda lokusika.

I-Autofocus Laser Cutting Head

Umbhede Oshiselwe Ishubhu elingunxande

Umbhede Oshiselwe Ishubhu elingunxande Elishiselwe Isakhiwo sangaphakathi sombhede samukela isakhiwo sekhekheba lezinyosi sensimbi yensimbi, esishiselwe ngamashubhu amaningana angunxande. Ama-stiffener ahlelwe ngaphakathi kwamashubhu ukukhulisa amandla namandla aqinile ombhede, futhi kwandisa ukumelana nokuzinza kwesitimela somhlahlandlela ukuze kugwenywe ngempumelelo ukuguqulwa kombhede. Amandla aphezulu, ukuzinza, amandla aqinile, ukuqinisekisa iminyaka engu-20 yokusetshenziswa ngaphandle kokuhlanekezela; Ubukhulu bodonga lwamapayipi angama-rectangular buyi-10mm, futhi isisindo singu-4500 kg.

- 01Igama Brand:MAX RAYCUS JPT IPG

- 02100000 amahora ukuphila isikhathi

- 03Izinzile, eyongayo

- 04Ukugcinwa kwamahhala

Umthombo we-Laser

UJALO WESIKWELA

Igama Brand: I-Taiwan HIWIN

Inzuzo: Umsindo ophansi, ayigugi, ishelela ukugcina isivinini Esihambayo sekhanda le-laser

Imininingwane: 30mm ububanzi kanye 165 izingcezu ezine isitokwe etafuleni ngalinye ukuze kwehliswe ingcindezi kajantshi

- 01Igama Brand:CYPCUT

- 02Imininingwane:umsebenzi wokufuna onqenqemeni kanye nomsebenzi wokusika endizayo, ukuhlela okuhlakaniphile kwe-ect

- 03Ifomethi esekelwe: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT, NC, GBX njll ...

uhlelo lokulawula

Imingcele Yezobuchwepheshe

- 01Imodeli YomshiniI-TSC-1313 / TSC-1530 / TSC-2040 / TSC-2065

- 02Umshini1300 * 1300mm / 1500 * 3000mm / 2000 * 4000mm / 2000 * 6500mm

- 03Laser Amandla1kw/2kw/3kw/4kw/5kw 6kw 12kw 20kw

- 04I-Laser GeneratorI-Raycus (Ngokuzikhethela: I-Max noma i-IPG)

- 05Isistimu yokulawulaI-Cypcut (olunye uhlobo lungakhethwa)

- 06Ukusika IkhandaI-Raytool (olunye uhlobo lungakhethwa)

- 07I-Servo Motor kanye nesistimu yomshayeliI-Japan Fuji (Ngokuzithandela i-Yaskwa noma i-Inovance)

- 08Isibandisi samanziI-S & A ( Hanli )

Imininingwane Yomkhiqizo

Isibonisi Sesampula

Indaba yesondlo

| Izinyathelo zokulungisa umshini wokusika i-laser | ||

| Isikhathi sokunakekela | Okuqukethwe kwesondlo | Ithagethi yesondlo |

| Usuku | 1. Hlola ukuthi izinga lokushisa le-chiller lijwayelekile yini (setha izinga lokushisa elingu-20±1℃) | Qinisekisa ukuthi amanzi okupholisa anikezwe i-laser asezingeni lokushisa elijwayelekile |

| 2. Hlola ukuthi isivalo sesekethe yamanzi, izinga lokushisa lamanzi kanye nomfutho wamanzi we-chiller kuyahlangabezana yini nezidingo. | Ukuqinisekisa ukusebenza okuvamile kwemishini futhi uvimbele ukuvuza kwamanzi | |

| 3. Qinisekisa ukuthi indawo yokusebenza ye-chiller yomile, ihlanzekile futhi ingena umoya | Ikhuthaza ukusebenza kahle kwe-chiller | |

| Inyanga | 1. Sebenzisa okokuhlanza i-Zhongbi noma insipho yekhwalithi ephezulu ukuze ususe ukungcola endaweni ebandayo. Ungasebenzisi i-benzene, i-asidi, impushana enukayo, ibhulashi lensimbi, amanzi ashisayo, njll. ukuze uhlanze. | Qinisekisa ukuthi ingaphezulu le-chiller lihlanzekile |

| 2. Hlola ukuthi i-condenser ivinjwe ukungcola. Sicela usebenzise umoya ocindezelweyo noma ibhulashi ukuze ususe uthuli ku-condenser ukuze uqinisekise ukuthi ingaphezulu le-chiller lihlanzekile. | Qinisekisa ukusebenza okuvamile kwe-condenser | |

| 3. Hlanza isihlungi somoya: a. Vula iphaneli lapho isihlungi somoya seyunithi sihlangene, donsa isihlungi somoya seyunithi bese usikhipha; b. Sebenzisa i-vacuum cleaner, isibhamu somoya kanye nebhulashi ukuze ususe uthuli esisefweni. Ngemva kokuhlanza, uma isihlungi simanzi, sinyakazise ukuze some ngaphambi kokusibuyisela. c. Umjikelezo wokuhlanza: kanye njalo emavikini amabili. Uma ukungcola kukubi, sicela ukuhlanze ngokungajwayelekile. | Vimbela ukupholisa okungekuhle okubangelwa ukupholisa okungekuhle kanye nokushiswa kwamaphampu amanzi nama-compressor | |

| 4. Hlola izinga lamanzi ethangini lamanzi bese ulandelela | Izinga elihle lamanzi lingaqinisekisa ukusebenza okuvamile kwe-laser | |

| 5. Hlola ukuthi akukho yini ukuvuza kwamanzi epayipini lokupholisa | Qinisekisa ukuthi akukho ukuvuza kwamanzi ku-chiller | |

| Ikota ngayinye | 1. Hlola izingxenye zikagesi (njengamaswishi, amabhulokhi wokugcina, njll.) bese usula ngendwangu eyomile. | Qinisekisa ukuthi ingaphezulu lezingxenye zikagesi ze-chiller zihlanzekile futhi wandise impilo yayo yesevisi |

| 2. Faka esikhundleni samanzi ajikelezayo (amanzi acwecwe), futhi uhlanze ithange lamanzi nesihlungi sensimbi; | Qinisekisa ukuthi i-laser isebenza kahle | |

| Uma ifakwe i-ROFIN laser, amanzi okupholisa angashintshwa kanye njalo ezinyangeni eziyisithupha ngemva kokwengeza ama-anti-corrosion inhibitors emanzini okupholisa. Uma ifakwe i-PRC laser, amanzi okupholisa angashintshwa kanye njalo ezinyangeni eziyisithupha ngemva kokwengeza i-propylene glycol emanzini okupholisa. | ||

| Amanothi: a. Beka i-chiller namapayipi amanzi kude nothuli. b. Khipha intambo yamandla kusokhethi bese uyisula ihlanzekile; c. Hlanza iyunithi yomzimba: Lapho uhlanza ingaphakathi leyunithi, ungavumeli amanzi achaphaze ezingxenyeni ze-electronic; d. Khipha ngokuphelele i-laser, ikhanda lokusika, nesipholile samanzi. ngaphandle. | ||